Quaternary ammonium salt cationic surfactant and application of chemical mechanical polishing solution

A technology of quaternary ammonium salt cations and surfactants, which is applied in the direction of polishing compositions containing abrasives, etc., and can solve the problems of high abrasive prices and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~22

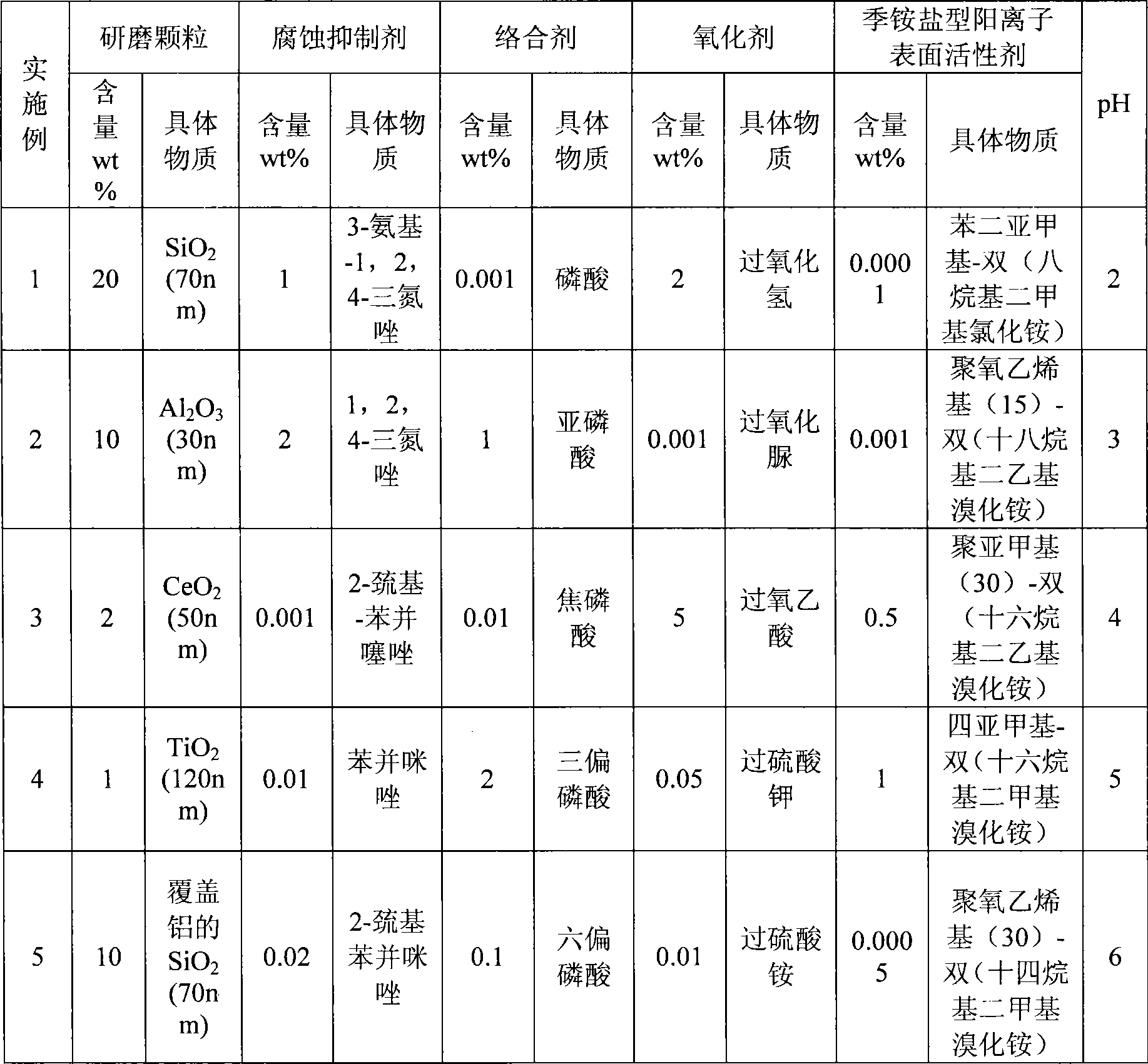

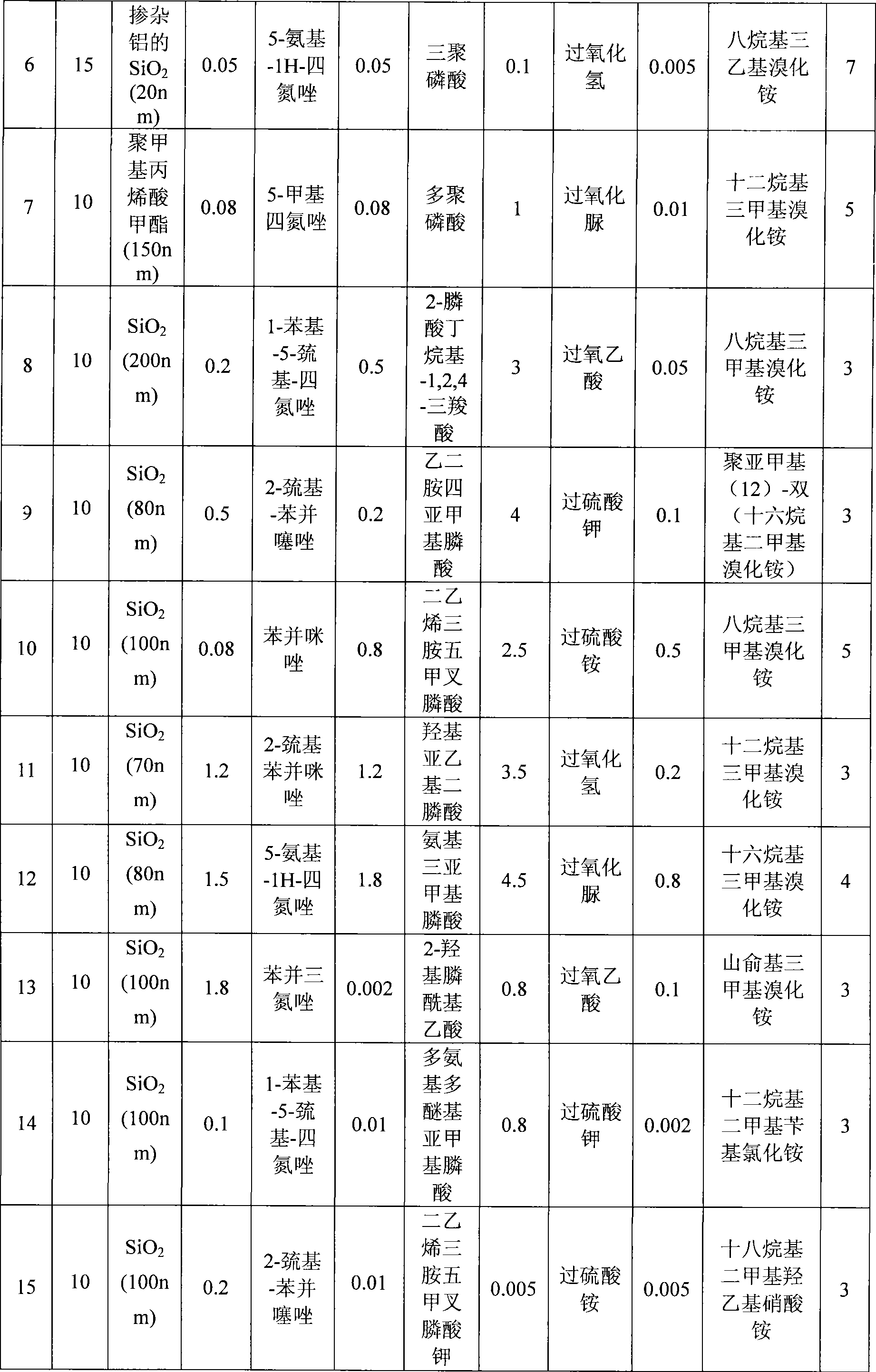

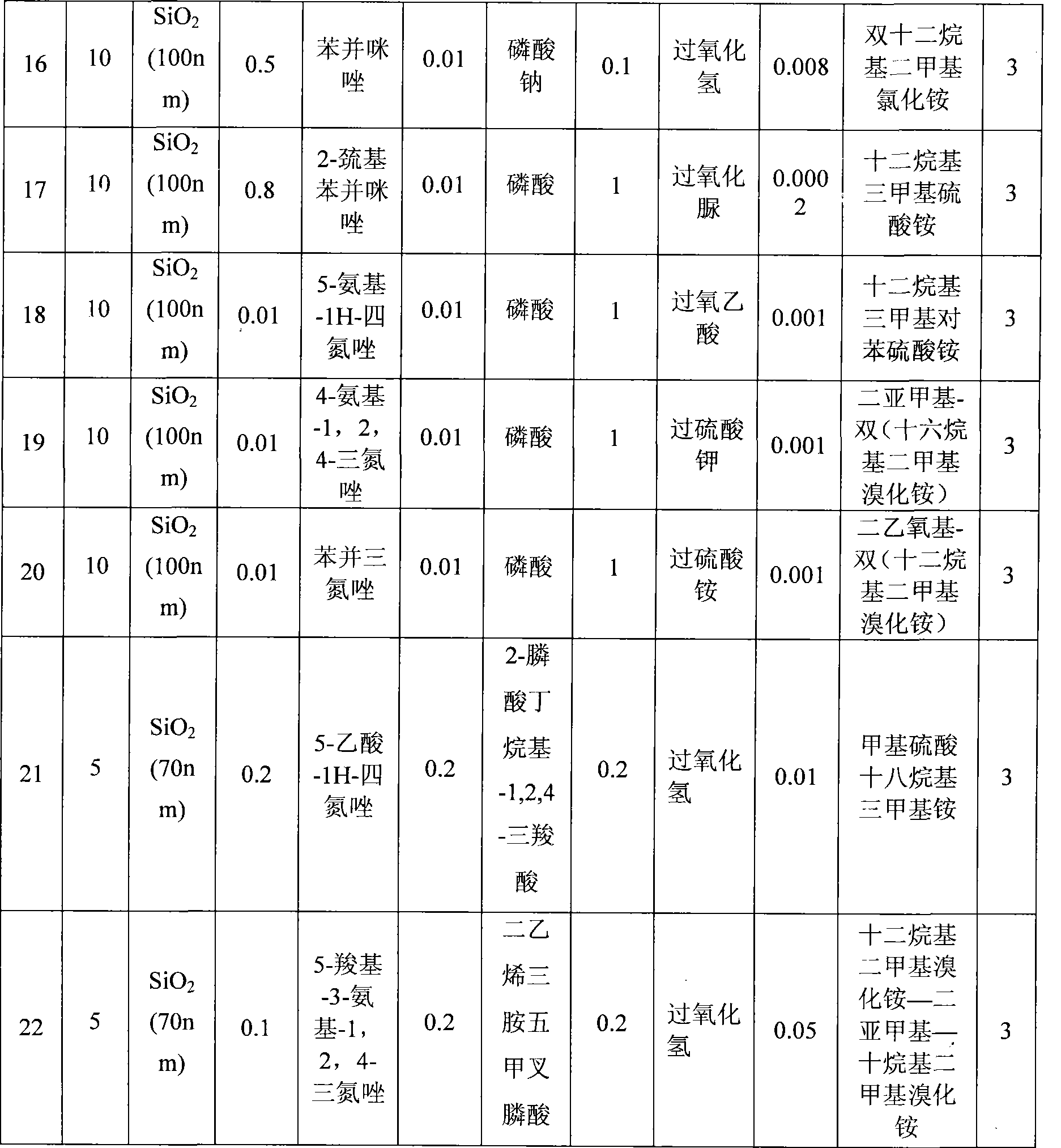

[0023] Table 1 shows examples 1-20 of chemical mechanical polishing fluids applied to the polishing of low-dielectric materials. According to the formula given in the table, mix other components except the oxidizing agent evenly, and use KOH or HNO 3 Adjust to desired pH. Add oxidant before use and mix evenly. Water makes up the mass percentage to 100%.

[0024] Table 1 Barrier Layer Chemical Mechanical Polishing Fluid Examples 1-22

[0025]

[0026]

[0027]

Embodiment 23~35

[0029] Examples 23-35 all contain 10wt% silicon dioxide (70nm), 0.1wt% benzotriazole, 0.01wt% phosphoric acid, 1wt% hydrogen peroxide, and 0.001wt% diethoxy-bis(dodecane dimethyl ammonium bromide), also contain polycarboxylate compound and / or its salt respectively, as shown in table 2. The preparation method is the same as above.

[0030] Table 2 embodiment 23~35 contained polycarboxylate compound and its pH

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com