A chemical mechanical polishing fluid

A chemical mechanical and polishing liquid technology, applied in the direction of polishing composition containing abrasives, etc., can solve the problems of difficult to meet the requirements of CMP polishing, low polishing, etc., and achieve the goal of overcoming uneven polishing rate, increasing selectivity ratio, and increasing polishing rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The raw materials selected in this embodiment are all commercially available. According to the formula in Table 1, all components are dissolved and mixed uniformly, and the mass percentage is made up to 100% with water. Potassium hydroxide (KOH) or nitric acid (HNO 3 ) to adjust the pH to 4.5, obtain specific examples as follows:

[0017] Table 1 comparative ratio and embodiment proportioning and concrete implementation result

[0018]

[0019] Carry out the chemical mechanical polishing of TEOS and SiN blank wafer respectively with the polishing solution prepared in the above-mentioned examples and comparative examples, and compare the polishing effects.

[0020] Polishing conditions: the polishing machine is Mirra, IC1010 polishing pad, the rotation speed of Platten and Carrier are 93rpm and 87rpm respectively, the pressure is 1.5psi, 2psi and 5psi, the flow rate of polishing liquid is 150mL / min, and the polishing time is 60 seconds. Polishing liquid 1A was used a...

Embodiment 2

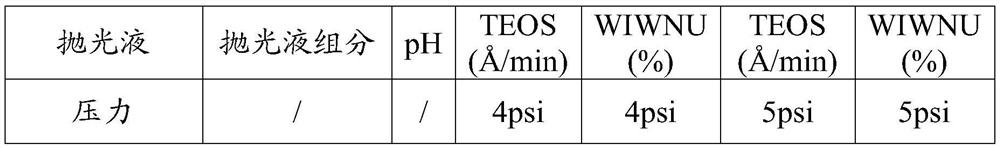

[0025] Table 2 Polishing effect list of polishing liquid of the present invention under different polishing pressures

[0026]

[0027]

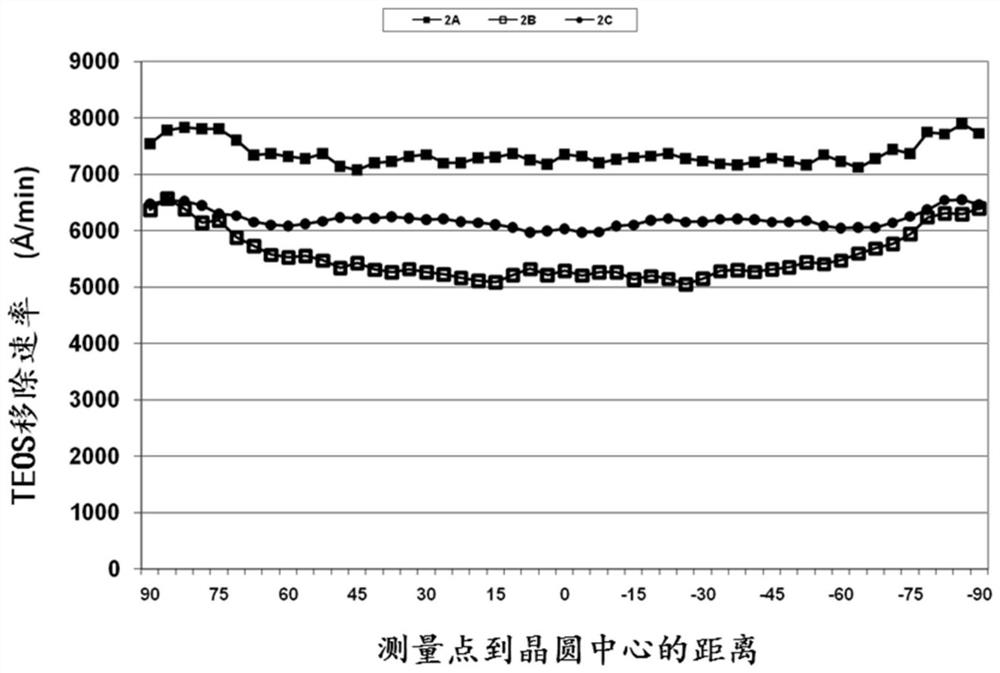

[0028] Carry out the polishing rate of TEOS blank wafer under different pressures respectively, the measurement of polishing rate non-uniformity (WIWNU) with the polishing liquid prepared in the above-mentioned embodiment and comparative example. Among them, the polishing conditions are: the polishing machine is Mirra, the IC1010 polishing pad, the rotation speed of Platten and Carrier are 93rpm and 87rpm respectively, the pressure is 4psi and 5psi, the flow rate of polishing solution is 150mL / min, and the polishing time is 60 seconds. The polishing performance of the polishing fluid was evaluated by the polishing removal rate corresponding to the TEOS blank wafer. Wherein, the TEOS polishing rate is calculated by measuring the before and after values of the TEOS film thickness. The TEOS film thickness is measured with a NanoSpec fi...

Embodiment 3

[0033] According to the formula in Table 4, dissolve and mix all components evenly, add potassium hydroxide (KOH) or nitric acid (HNO 3 ) to adjust the pH to 4.5, obtain specific examples as shown in the table below, wherein, benchmark 3A is the same as the composition and content thereof of the 1A polishing fluid of benchmark in table 1:

[0034] Table 4 embodiment proportioning and concrete implementation result

[0035]

[0036] The polishing liquid prepared in the above examples was respectively subjected to chemical mechanical polishing of TEOS blank wafer and SiN, and the polishing effects were compared. The polishing conditions are as follows: the polishing machine is Mirra, IC1010 polishing pad, the rotation speed of Platten and Carrier are 93rpm and 87rpm respectively, the pressure is 1.5psi, 2psi and 5psi, the flow rate of polishing solution is 150mL / min, and the polishing time is 60 seconds. Each polishing solution contains sol-type cerium oxide, and the solid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com