Material loading system for producing marsh gas by utilizing straw fermentation

A straw and feeding technology, which is applied in the field of feeding system, can solve the problems of easy falling behind, blockage of pipelines, affecting the gas production of the digester, etc., and achieve the effect of preventing blockage, ensuring raw materials and ensuring output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

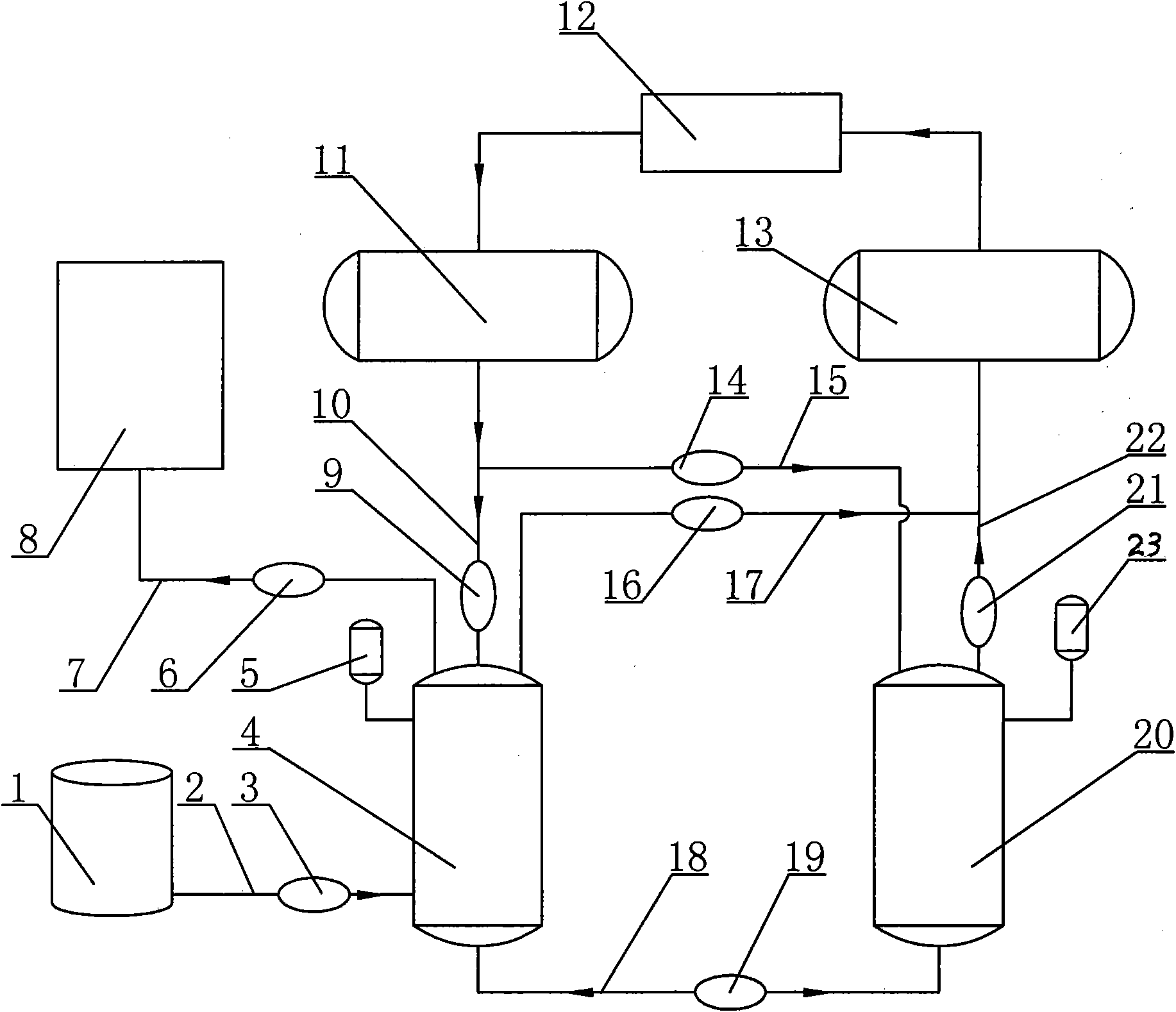

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the feeding tank 4 is connected to the straw mixing pool 1 through a pipeline 2, and the pipeline 2 is provided with a valve 3, and the feeding tank 4 is connected to the anaerobic digester 8 through a pipeline 7, and the pipeline 7 is provided with a valve 6. Tank 4 is connected with positive pressure tank 11 through pipeline 10, and pipeline 10 is provided with valve 9, and feeding tank 4 is connected with negative pressure tank 13 through pipeline 17, and pipeline 17 is provided with valve 16, and feeding tank 4 is connected with pipeline 18 and The feeding auxiliary tank 20 is connected, the pipeline 18 is provided with a valve 19, the feeding auxiliary tank 20 is connected with the positive pressure tank 11 through the pipeline 15, the pipeline 15 is provided with a valve 14, the feeding auxiliary tank 20 and the negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com