Length control method of metal powder rolled raw plate blank top crop

A technology of metal powder and control method, which is applied in the field of cutting length control of metal powder rolled green slabs, can solve problems such as waste of raw materials, lower quality of sintered products, and excessive length of cutting ends, so as to improve product quality and realize the best The effect of optimizing and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

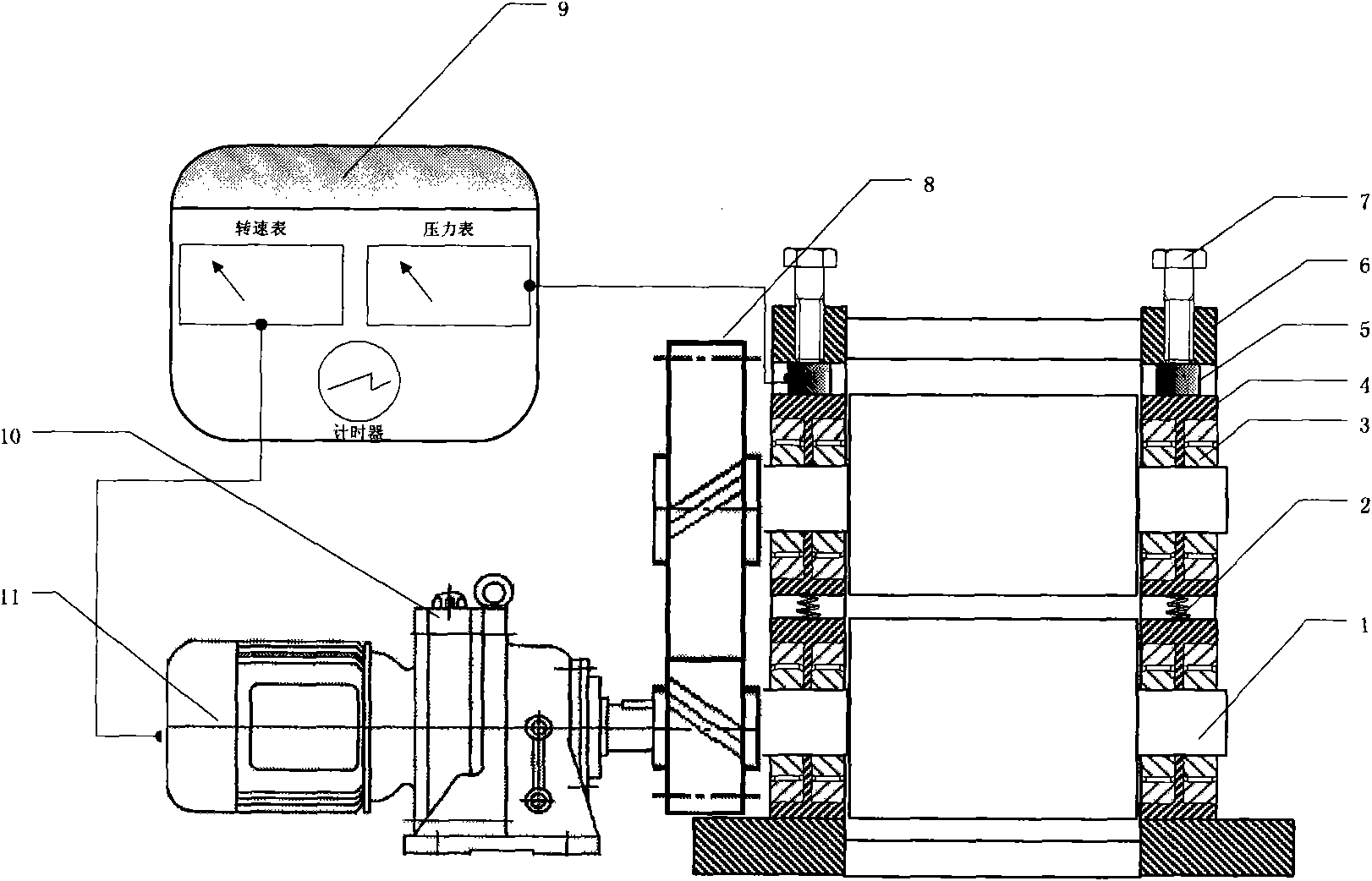

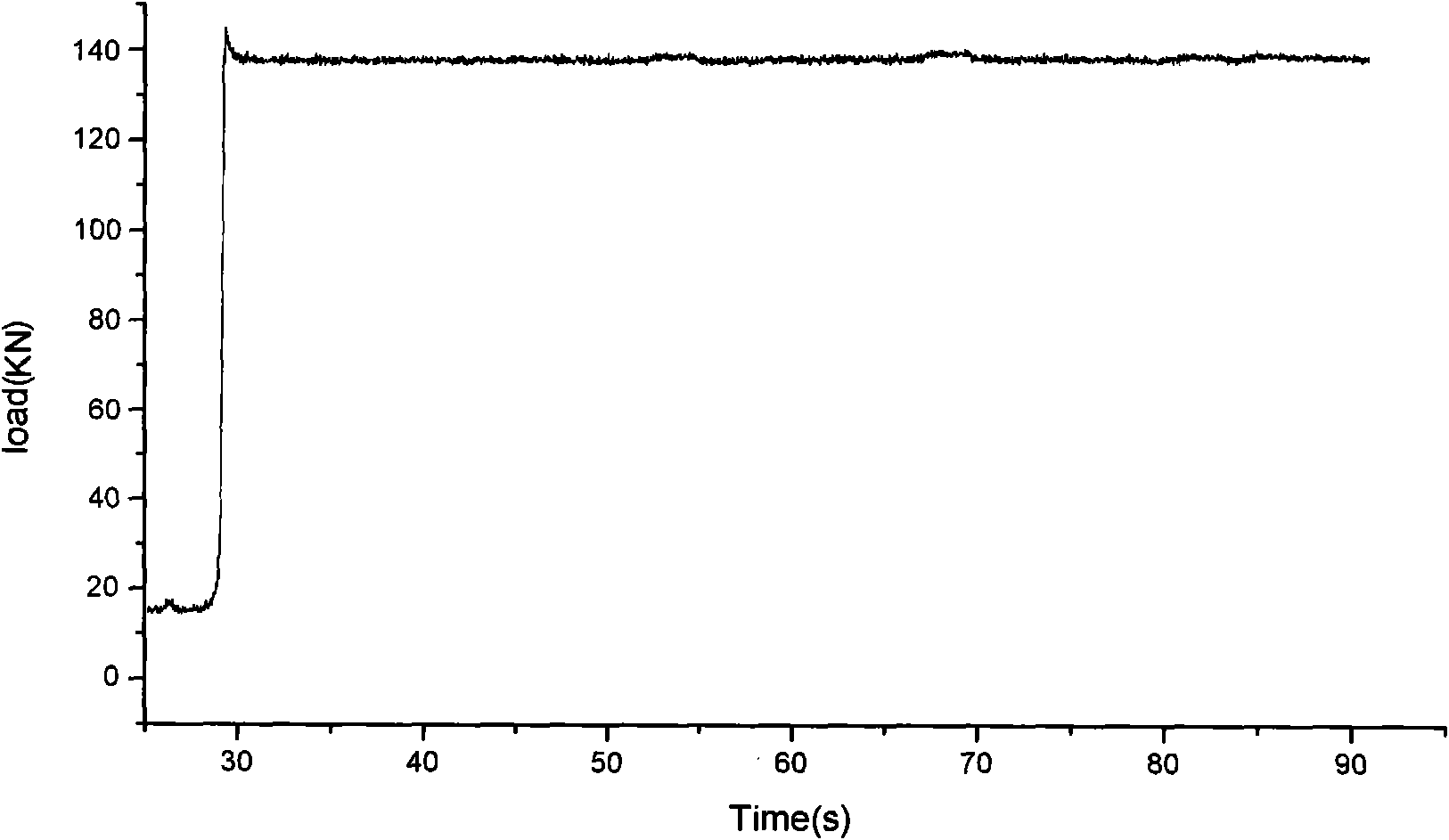

[0015] Embodiment: In this embodiment, tungsten-copper alloy powder is used, and the powder is placed between two rolls of a special rolling equipment with a rolling pressure electronic sensing system device, and then the motor is started for rolling operation. And obtain the change trend or change curve of the pressure with time recorded by the ad hoc pressure electric sensor system, and obtain the cut length of the green slab through the time taken for the rolling pressure to reach a steady state and the rotation speed of the roll.

[0016] The rolling equipment used in this embodiment can be found in figure 1 . figure 1 It is a schematic diagram of the rolling equipment with the pressure electronic sensing system device of the present invention.

[0017] Such as figure 1 As shown, this special device is improved on the basis of traditional original general-purpose rolling equipment. The system device includes: a pair of rollers 1, spring 2, roller bearing 3, bearing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com