Fully automatic moulding press for moulding small plastic parts

A fully automatic, molding machine technology, applied in engine components, mechanical equipment, multi-way valves, etc., can solve problems such as poor control of product accuracy, difficulty in machine maintenance and maintenance, and inconvenience in maintenance and repair, so as to reduce maintenance costs. , The pipeline layout is clear, easy to repair and maintain the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

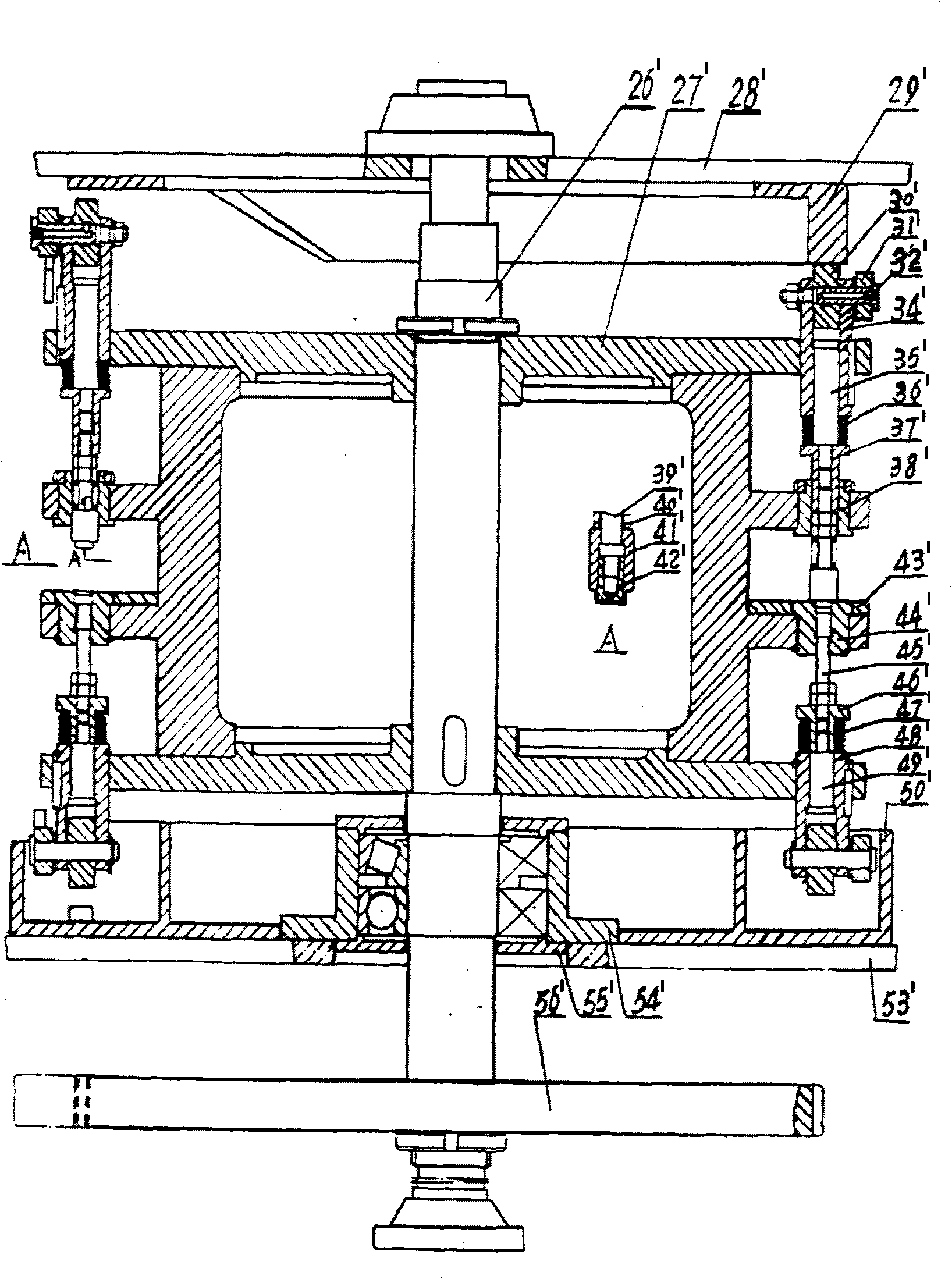

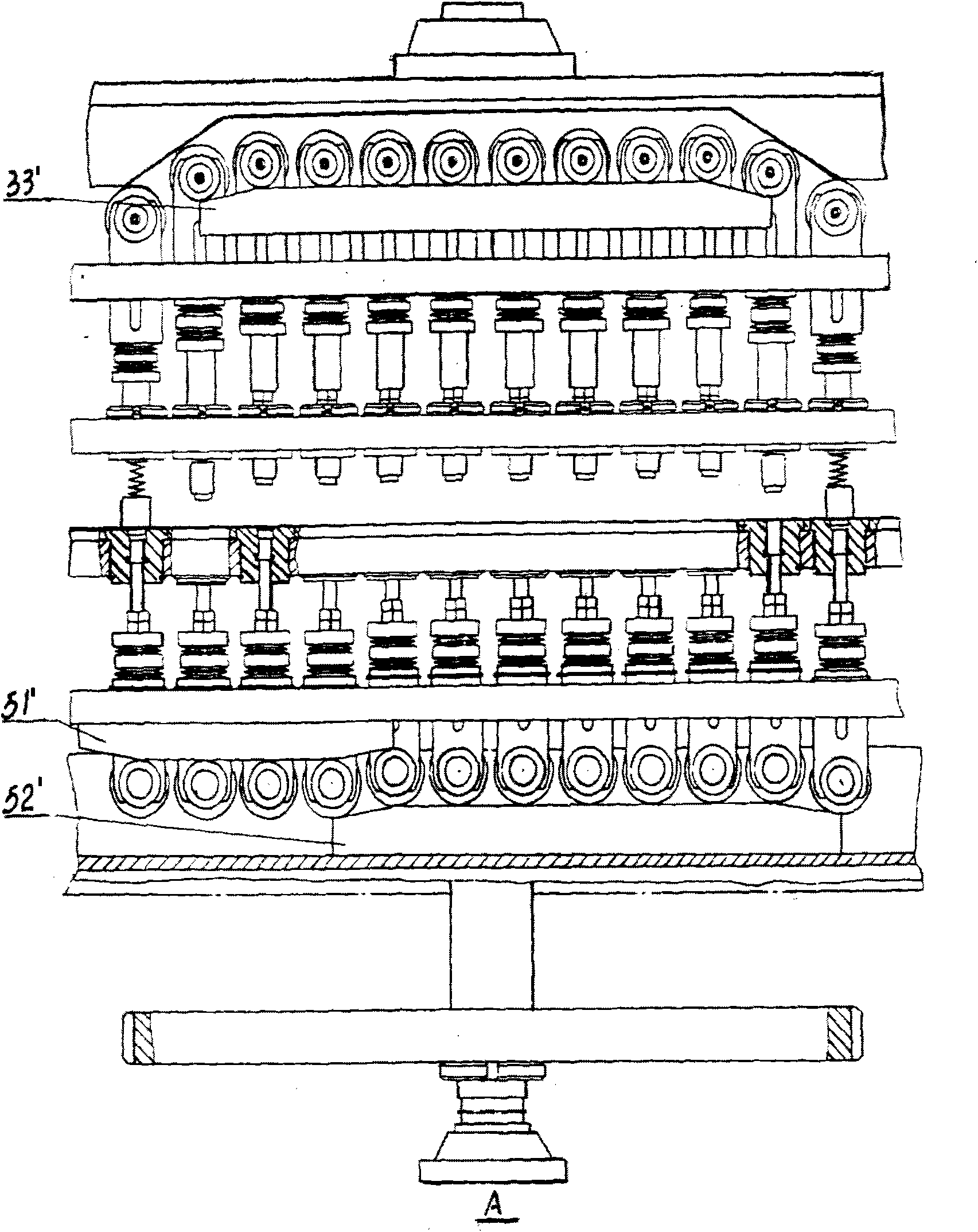

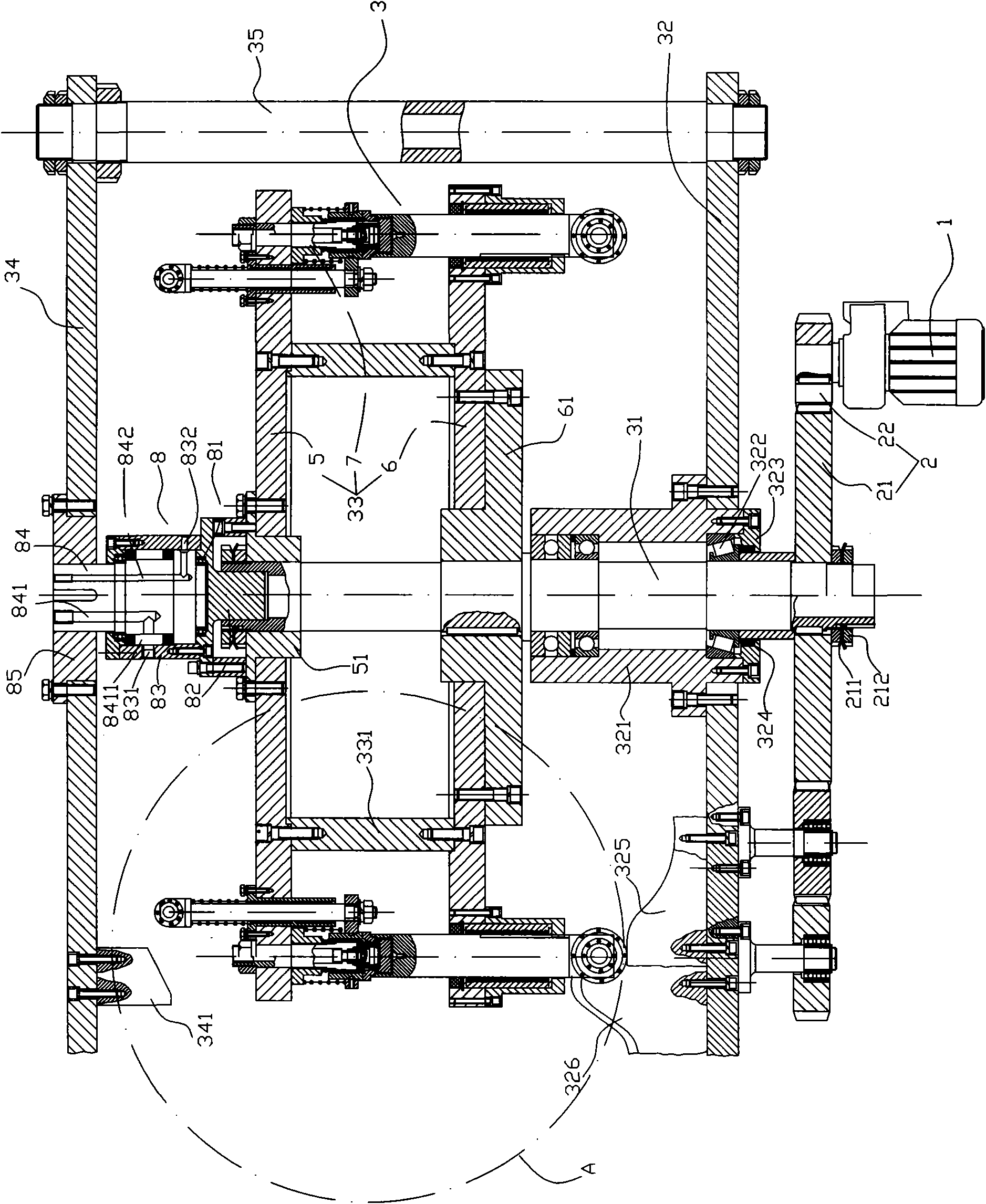

[0015] Such as image 3 and Figure 4 As shown, the fully automatic small-sized plastic molding molding machine includes a power unit 1, a molding unit 3 connected to the power unit through a gear set 2, and a mold cooling system, wherein the molding unit 3 includes a main shaft 31, a lower base plate 32, and a molding seat 33 and upper cover plate 34.

[0016] The main shaft 31 is connected with the power unit motor 1 through the gear set 2 at the end. In the present invention, the gear set 2 is composed of a bull gear 21 and a driven pinion 22 , wherein the bull gear 21 and the main shaft 31 are fixedly connected through a stop washer 211 and a round nut 212 .

[0017] The lower bottom plate 32 is fixed on the base of the molding machine and remains stationary. It is sealed with the main shaft 31 by the main shaft seat 321, the oblique bearing 322, the bearing cover 323 and the oil seal block 324. A mold closing guide rail 325 and a mold opening guide rail 326 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com