Reversible repair composition, preparation method thereof, varnish composition and self-repairing coating material

A composition and reversible technology, applied in coatings, polyurea/polyurethane coatings, layered products, etc., can solve the problems of poor scratch resistance, self-healing performance, and poor UV radiation resistance, and achieve scratch resistance Excellent, good UV radiation resistance, excellent self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

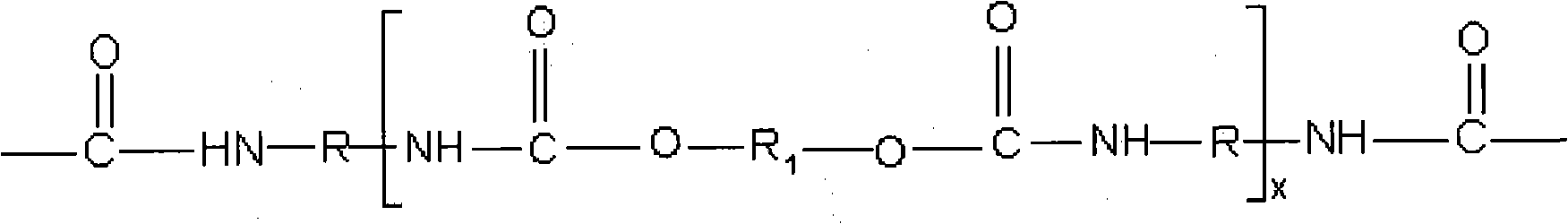

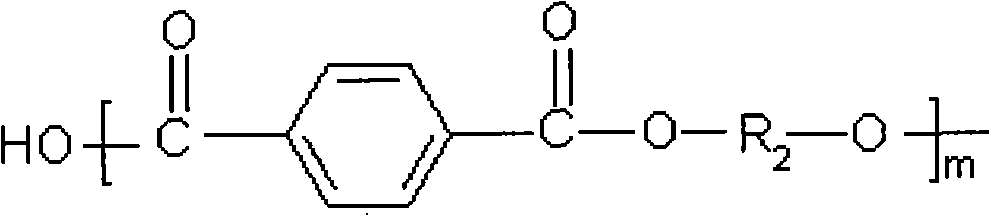

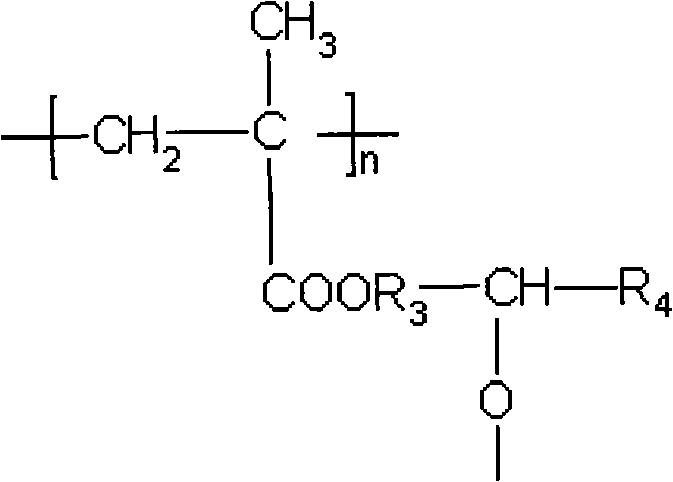

[0034] The present invention also provides a preparation method of the reversible restoration composition, the method comprising: under esterification reaction conditions, carrying out esterification reaction with aliphatic and / or aromatic diisocyanate and organic dihydric alcohol, and combining the obtained reaction product with The alcoholic hydroxyl-containing polyacrylate and the alcoholic hydroxyl-containing polyester undergo esterification reaction under the esterification reaction conditions in the presence of a catalyst.

[0035] In the method, the conditions of the esterification reaction of aliphatic and / or aromatic diisocyanate and organic dibasic alcohol include that the molar ratio of aliphatic and / or aromatic diisocyanate and organic dibasic alcohol can be 1.5- 3:1, the reaction temperature can be 160-180°C, and the reaction time can be 6-8 hours.

[0036] The esterification reaction product of aliphatic and / or aromatic diisocyanate and organic dihydric alcohol, ...

Embodiment 1

[0073] This example is used to illustrate the reversible repair composition, varnish composition and self-repair coating material provided by the present invention and the manufacturing method thereof.

[0074] (1) Preparation of reversible repair composition

[0075] In a 2-liter three-necked flask with a stirring device, at a stirring speed of 1000 rpm, 10 moles of methyl diisocyanate (produced by Tianjin Madison Chemical Industry Co., Ltd.) and 4 moles of 1,10-decanediol (produced by Shantou, Guangdong) City Xilong Chemical Factory) and 4.5 moles of propylene glycol methyl ether acetate (Guangdong Guanghua Chemical Factory Co., Ltd.) carried out esterification reaction at 160 ° C for 8 hours to generate polyurethane with -NCO at both ends (through gel permeation chromatography The degree of polymerization recorded by the method is 10); then, 1 mole of ethylene terephthalate (Beijing Hengye COSCO Chemical Co., Ltd.), 2 moles of polyhydroxypropyl methacrylate (Beijing Hengye ...

Embodiment 2

[0082] This example is used to illustrate the reversible repairing composition provided by the present invention and its preparation method, as well as the varnish composition and self-repairing coating material provided by the present invention and its manufacturing method.

[0083] (1) Preparation of reversible repair composition

[0084] In a 2-liter three-neck flask with a stirring device, at a stirring speed of 1000 rpm, 9 moles of ethyl diisocyanate (produced by Tianjin Madison Chemical Industry Co., Ltd.), 3 moles of 1,7-heptanediol (Beijing Heng Industry COSCO Chemical Co., Ltd.), 3 moles of butyl acetate (Guangdong Guanghua Chemical Factory Co., Ltd.) and 3 moles of diacetone alcohol (Guangdong Guanghua Chemical Factory Co., Ltd.) at 165 ° C for 7.5 hours to generate two ends Polyurethane with -NCO (the degree of polymerization measured by gel permeation chromatography is 7); then, 1 mole of poly-1,7-heptanediol terephthalate (Beijing Hengye COSCO Chemical Co., Ltd.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com