Method for paving combination paving layer for tunnel road surface

A paving layer and road surface technology, applied in the field of building materials, can solve the problems of life safety, poor driving comfort, low sound absorption coefficient, etc., achieve good isolation effect, improve anti-skid ability, and good fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

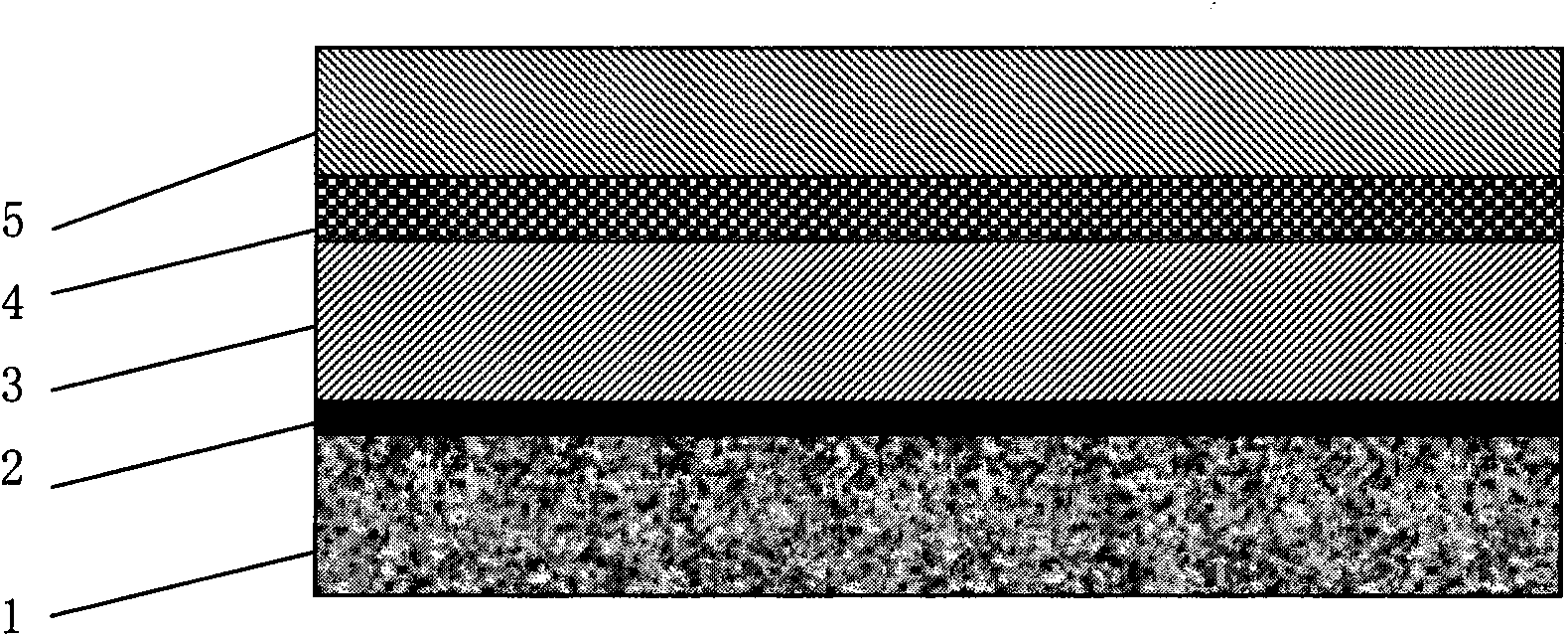

[0074] Such as figure 1 Shown, a kind of pavement method of tunnel pavement composite pavement, it comprises the steps:

[0075] 1) Preparation of flame-retardant high-viscosity modified asphalt:

[0076] Flame-retardant high-viscosity modified asphalt is composed of styrene-butadiene-styrene block copolymer (SBS), tackifier, compatibilizer, stabilizer, flame-retardant and smoke suppressant and base asphalt. The mass of each component The ratio is base asphalt: styrene-butadiene-styrene block copolymer: tackifier: compatibilizer: stabilizer: flame retardant and smoke suppressant = 100: 7.0: 1.5: 6.0: 0.5: 7.0; Add styrene-butadiene-styrene block copolymer after the base asphalt is melted, stir at a low speed of 10min at 150°C, then pass through a high-speed shearing machine, stir at a high speed of 45min at 160°C, and the speed is 3000r / min. Then place it at 140°C for 60 minutes to make it fully swell, and finally add tackifier, compatibilizer, stabilizer and flame retardant...

Embodiment 2

[0113] A pavement method for a combined pavement layer of a tunnel pavement, comprising the steps of:

[0114] 1) Preparation of flame-retardant high-viscosity modified asphalt:

[0115] Flame-retardant high-viscosity modified asphalt is composed of styrene-butadiene-styrene block copolymer (SBS), tackifier, compatibilizer, stabilizer, flame-retardant and smoke suppressant and base asphalt. The mass of each component The ratio is base asphalt: styrene-butadiene-styrene block copolymer: tackifier: compatibilizer: stabilizer: flame retardant and smoke suppressant = 100: 11.2: 3.0: 13.9: 1.2: 11.6; Add styrene-butadiene-styrene block copolymer after the base asphalt is melted, stir at a low speed of 15min at 170°C, then pass through a high-speed shearing machine, stir at a high speed of 60min at 180°C, and the speed is 4000r / min, Then place it at 150°C for 90 minutes to make it fully swell, and finally add tackifier, compatibilizer, stabilizer and flame retardant and smoke suppr...

Embodiment 3

[0152] A pavement method for a combined pavement layer of a tunnel pavement, comprising the steps of:

[0153] 1) Preparation of flame-retardant high-viscosity modified asphalt:

[0154] Flame-retardant high-viscosity modified asphalt is composed of styrene-butadiene-styrene block copolymer (SBS), tackifier, compatibilizer, stabilizer, flame-retardant and smoke suppressant, and base asphalt. The mass of each component The ratio is base asphalt: styrene-butadiene-styrene block copolymer: tackifier: compatibilizer: stabilizer: flame retardant and smoke suppressant = 100: 5.2: 1.0: 5.0: 0.2: 6.5; Add styrene-butadiene-styrene block copolymer after the base asphalt is melted, stir at a low speed of 10 minutes at 150°C, and then pass through a high-speed shearer, stir at a high speed of 45 minutes at 160°C, and the speed is 3000r / min. Then place it at 140°C for 60 minutes to make it fully swell, and finally add tackifier, compatibilizer, stabilizer and flame retardant and smoke su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com