Digitizing detection method of complicated curved face

A complex curved surface and detection method technology, applied in the field of digital detection of complex curved surfaces, can solve problems such as inability to guarantee accuracy, affect calculation accuracy, and large amount of calculation, so as to improve measurement accuracy, simplify calculation process, and achieve good detection accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

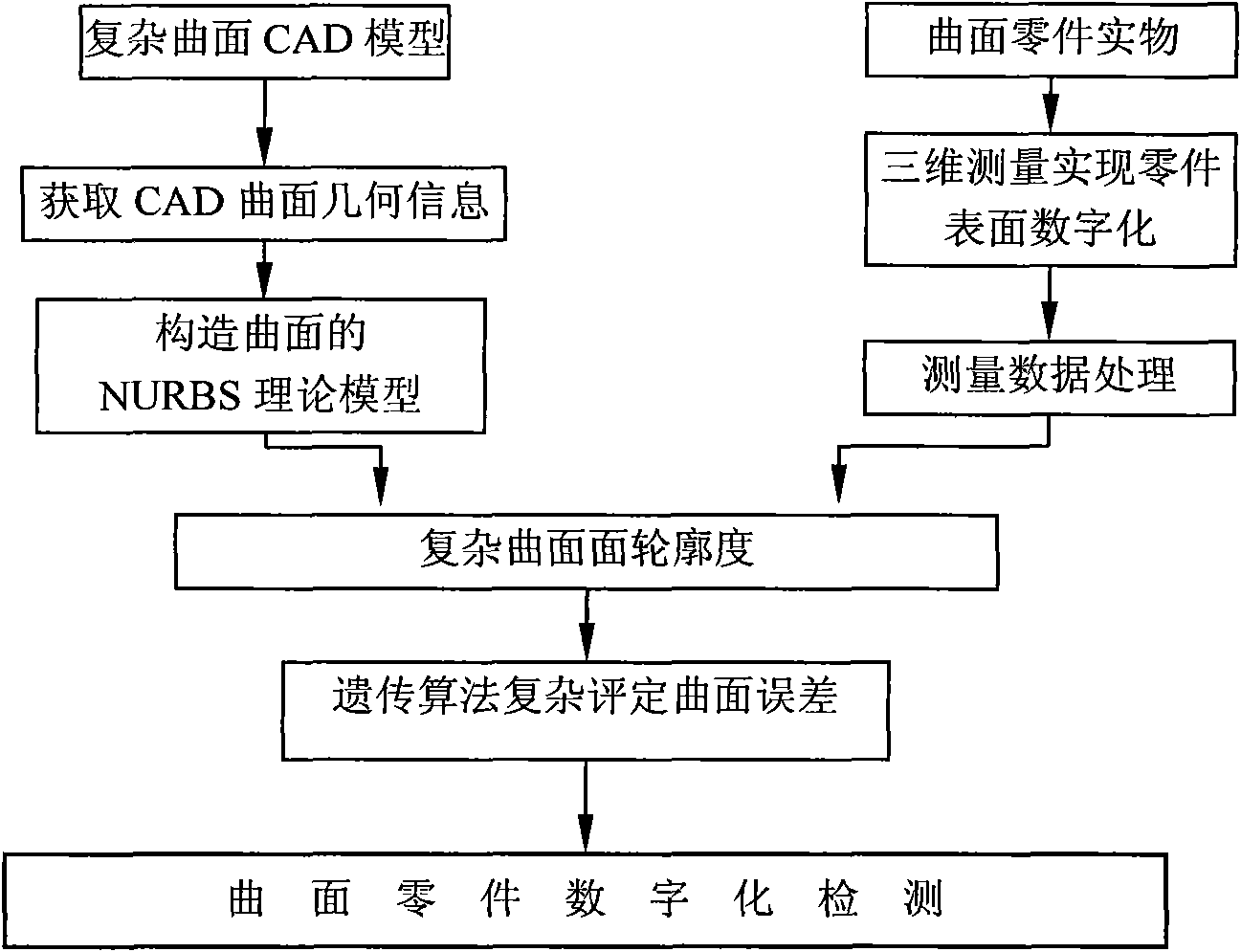

[0033] A digital detection method for complex curved surfaces, the process of which is as follows figure 1 As shown, the method includes the following steps:

[0034] (1) Extract the geometric data of the CAD model of the complex surface, establish the NURBS theoretical model of the complex surface, and then use the three-dimensional measurement of the actual surface part to digitize the surface of the part to obtain the measurement point parameters;

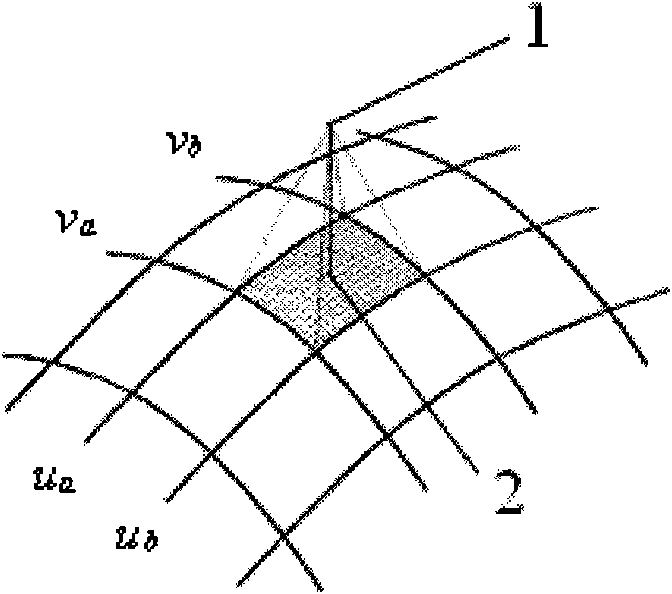

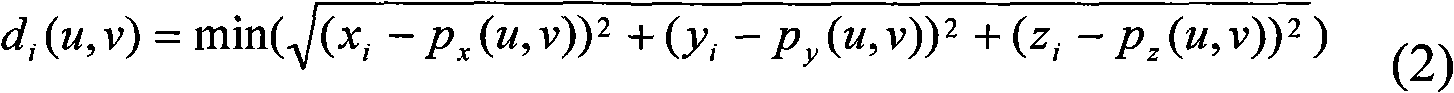

[0035] (2) Construct the isoparametric line area by searching two sets of isoparametric line closest to the measuring point on the CAD surface, and establish the binary nonlinear mathematical model of the minimum distance from the measuring point to the surface isoparametric line area;

[0036] (3) The genetic algorithm is used to calculate the shape error of the complex surface, and the error evaluation of the complex surface is realized.

[0037] Using the NURBS method to describe the theoretical model of the CAD surface, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com