Method for manufacturing artificial bionic compound eyes

A bionic compound eye and production method technology, applied in the field of interdisciplinary research, can solve the problems of low machining accuracy and difficult precision machining of spherical microlenses, so as to reduce the production cost, improve the ability of mass production, and overcome the light dispersion effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

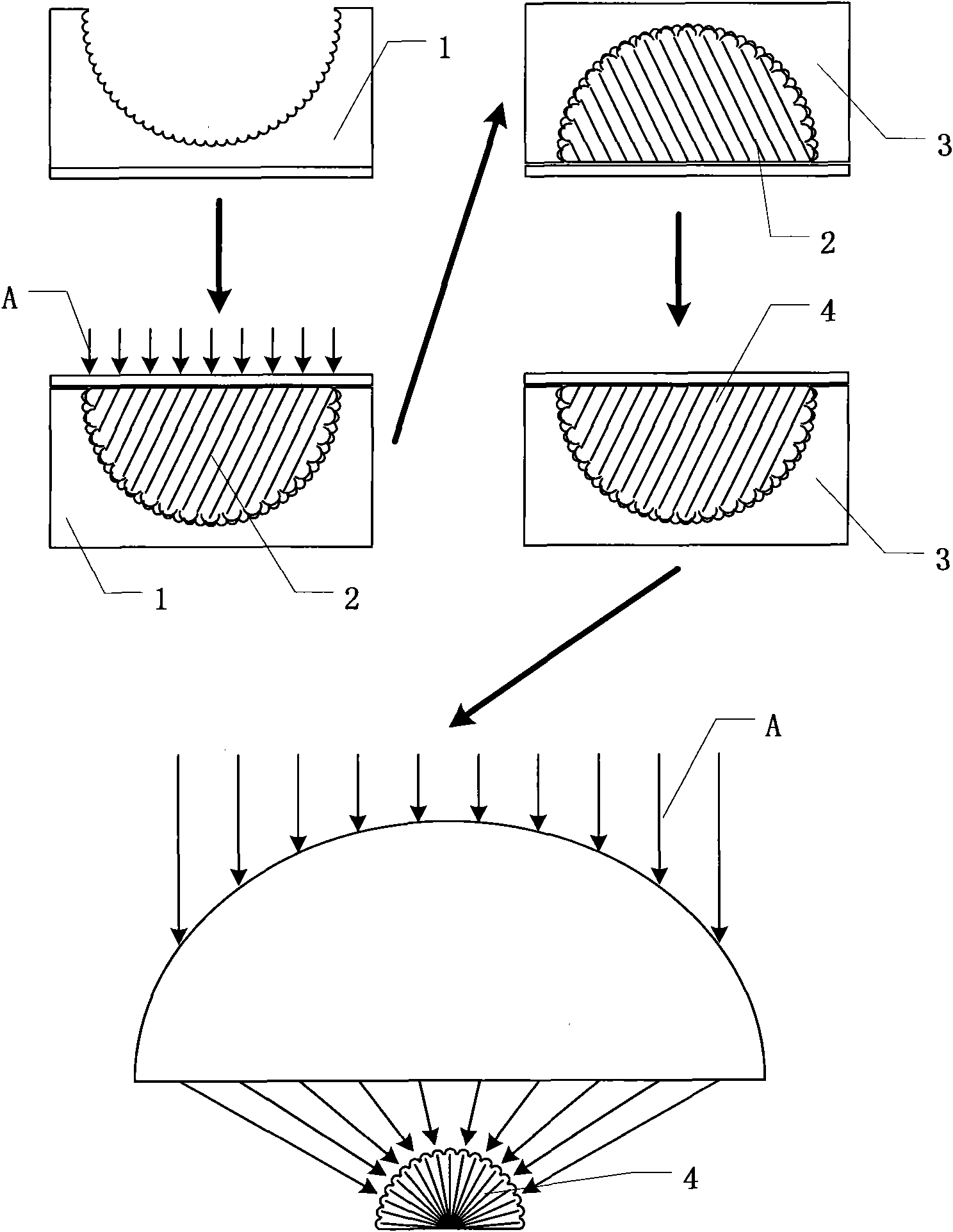

[0014] The present invention describes a manufacturing method of an artificial bionic compound eye. The technical solution is different from the existing artificial bionic compound eye manufacturing method, and the femtosecond pulse two-photon polymerization technology is used to manufacture an artificial compound eye structure. As the only two-photon polymerization technology that can precisely control and fabricate any three-dimensional micro-nano structure, it undoubtedly has unique advantages in fabricating complex artificial compound eyes. Combined with the recently developed ultraviolet nanoimprinting (UV-NIL) and soft lithography technology, polydimethylsiloxane PDMS (Poly-Dimenthylsiloxane) can be used to fabricate a biologically similar three-dimensional polymer optical system that breaks through the traditional framework. This breakthrough in exploratory research will have broad application prospects in many fields of optical applications, such as data storage and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com