Minitype tightly packaged fiber unit and production method thereof

A kind of optical fiber unit, miniature technology, applied in the field of miniature tight-packed optical fiber unit and its production, can solve the problems such as inability to produce miniature stainless steel optical fiber unit, achieve light weight, improve the performance of lateral pressure resistance, and improve the effect of bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

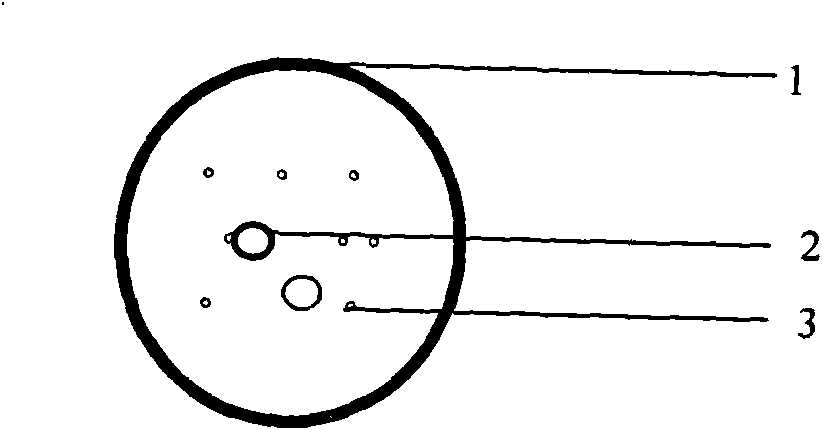

[0017] Refer to attached figure 1 , The structure of the miniature tight-packed stainless steel optical fiber unit includes optical fiber 2, optical fiber ointment 3, and stainless steel tube 1. An optical fiber 2 is installed in the stainless steel tube 1 and filled with optical fiber ointment 3 to form an optical fiber unit.

[0018] The production method of miniature tight-packed stainless steel optical fiber unit is as follows:

[0019] 1. Put the stainless steel coils on the steel belt rack, and then pull the steel belt to the steel pipe forming table through the steel belt tractor. The tension of the belt should be stable and there should be no shaking. The tension of the belt should be controlled at 80~90N.

[0020] 2. At the steel pipe forming table, the stainless steel strip is cut to the width required by the forming mold. The stainless steel strip is 6.2-6.3mm wide and 0.15-0.2mm thick, and then enters the φ2.0mm steel pipe forming mold. Wrap it into a stainless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Traction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com