Macromolecular multifunctional binder

A multi-functional, adhesive technology, applied in the direction of adhesives, etc., can solve the problems of human toxicity, easy to fall off, low bonding strength, etc., and achieve the effect of prolonging the service life, good weather resistance and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

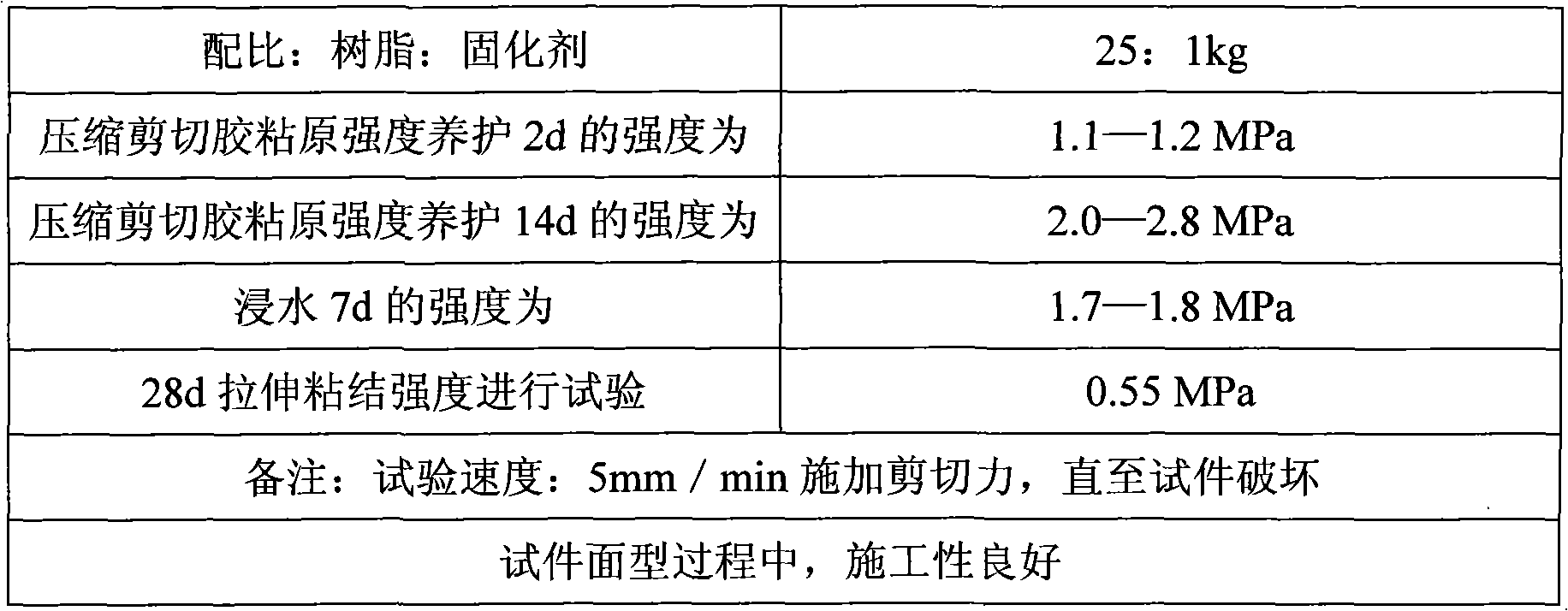

[0037] A polymer multifunctional adhesive, which is formed by mixing adhesive component A and curing agent B, and its proportion is: A: 100%, B: 4%;

[0038] Adhesive component A is prepared by mixing the following ingredients:

[0039] Ortho-phthalic general-purpose unsaturated polyester resin 35.7%

[0040] Silicone ethylene, vinyl acetate copolymer 1%

[0041] Thickener Polyacrylamide 2%

[0042] Lubricant Glycerin 0.3%

[0043] Fly Ash A 1 Grade 5%

[0044] Talc powder 56%≥350 mesh

[0045] Curing agent B is made by mixing the following components:

[0046] Curing agent methyl ethyl ketone peroxide 78

[0047] Thickener polyacrylamide 0.05

[0048] Talc powder, fineness ≥ 350 mesh 22.

[0049] Adhesive component A and curing agent B are packaged separately. When used, the amount of curing agent B is 4% of the adhesive component A. After mixing the adhesive component A and curing agent B, it can be pasted after one minute of stirring. It hardens after an hour. Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com