Method for packaging light emitting diode

A technology of light-emitting diodes and thermoplastic materials, applied in chemical instruments and methods, electrical components, circuits, etc., can solve the problems of easy yellowing, non-recyclability, and UV resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

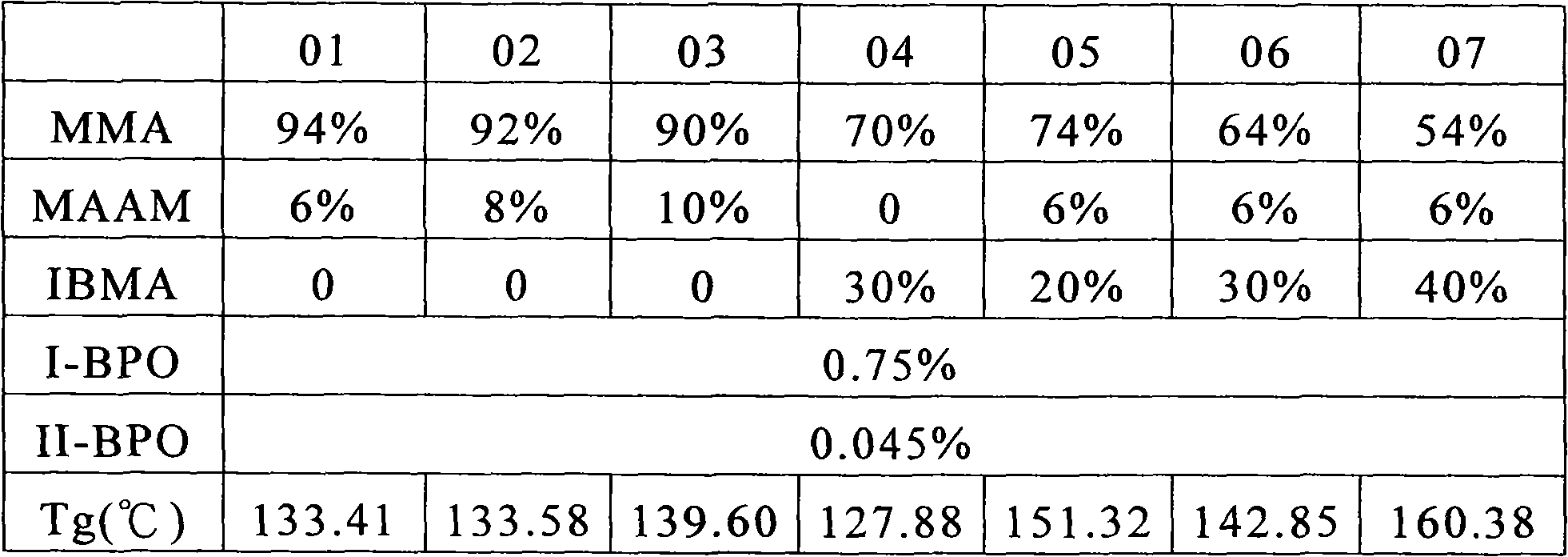

Embodiment 1

[0016] Acrylic esters such as methacrylate (MMA), hydrogen-bonding monomers such as methacrylamide (MAAM for short), macrosteric barrier monomers such as isobomyl methacrylate (isobomyl methacrylate, short for short) were used in different weight ratios. IBMA), and the first-stage thermal initiator benzoyl peroxide (benzoyl peroxide, I-BPO for short), react at 60° C. to 80° C. for 1-3 hours. When the viscosity of the above mixture increases, add the thermal initiator benzoyl peroxide (II-BPO for short) in the second stage and lower the temperature to 40°C to 60°C, and react for about 0.5-3 hours. Finally, the above mixture was placed in an oven and reacted at 90° C. for two hours and at 130° C. for two hours to complete the block polymerization reaction. After the reaction, properties such as Tg, transparency, and UV yellowing resistance of the copolymer were measured. The weight ratio of the above reactants and the physical properties of the formed copolymer are shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com