Atmospheric pressure microwave plasma treated porous membranes

A plasma, microporous membrane technology, applied in the direction of plasma, membrane, membrane technology, etc., can solve the problem of no preparation, no dewetting, no modification of thin porous membranes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

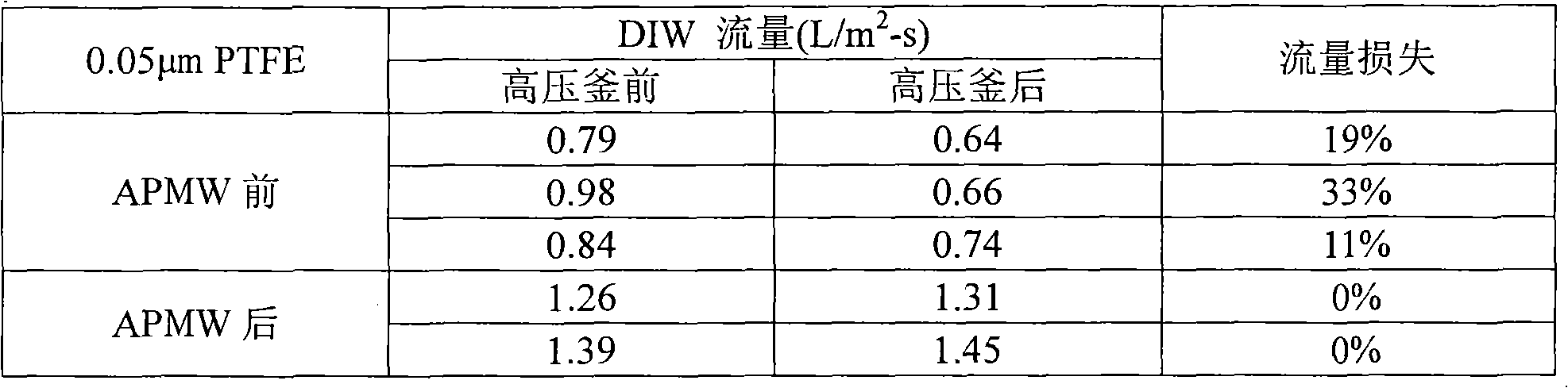

[0062] The present invention may include porous membranes and their method of preparation, wherein said porous membranes are treated with APMW plasma in the presence of gas initially present or injected into a plasma device, wherein the treated Improved contact wettability of porous membranes. For example, gases such as noble gases (such as helium or argon), reactive gases (such as oxygen), inert gases (such as nitrogen), purified sources of inert or rare gases, or relatively Complex gas molecules (such as carbon dioxide and ammonia). In various embodiments, these gases may be used in mixtures (two or more gases). Examples of suitable mixtures that may be used may include, but are not limited to, air, a source of ultra-clean dry air to which controlled amounts of steam such as water or other oxygenated liquids are added (see International Publication No. WO 2005 / 010619, Lithographic Projection Apparatus , Gas Purging Method, Device Manufacturing method and Purge Gas Supply S...

Embodiment 1

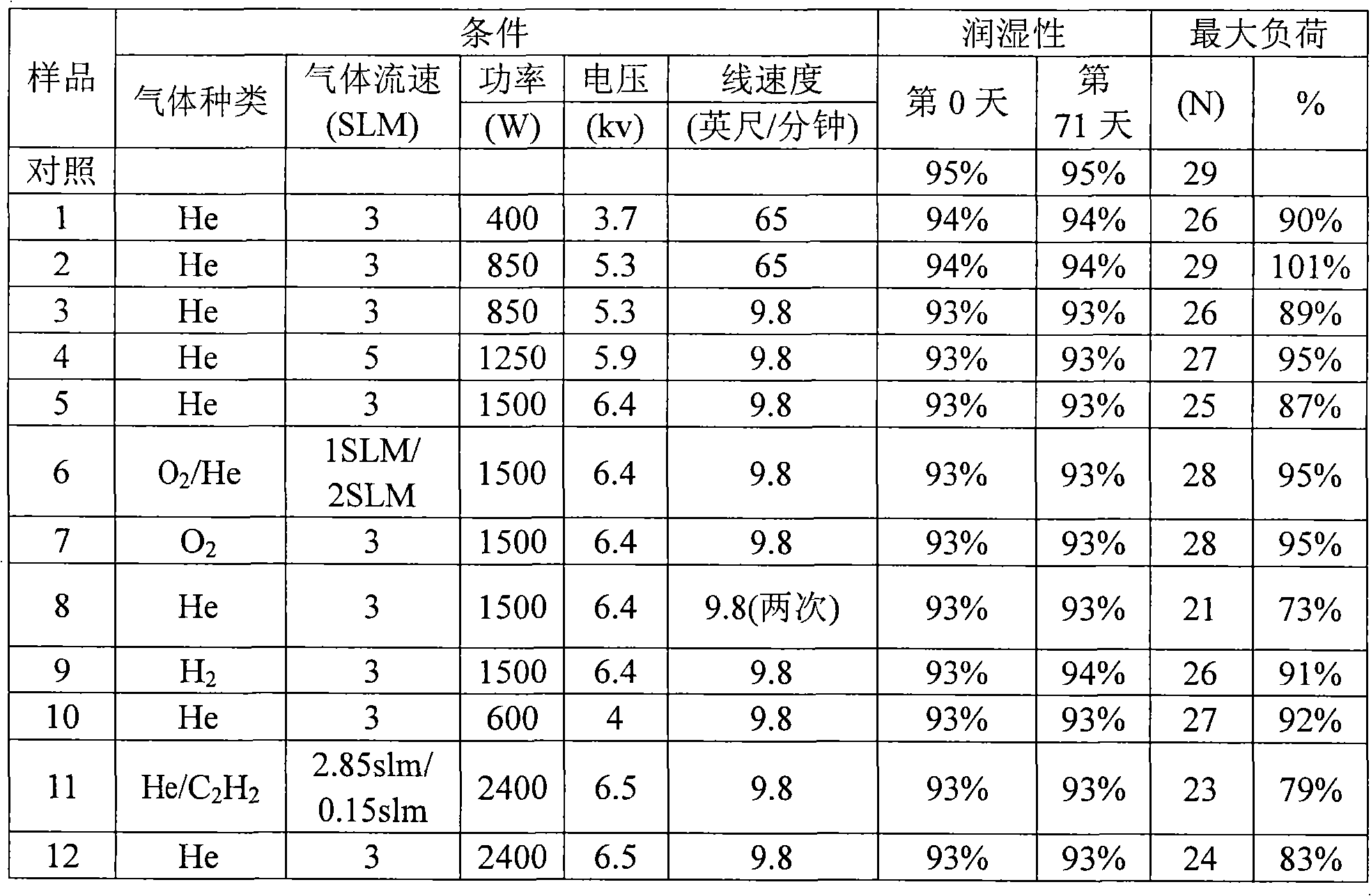

[0097] Atmospheric pressure microwave plasma treatment was performed on multilayer (support, filter layer, support) 0.03 micron PTFE membrane samples with different gas types, flow rates, power, voltage and processing time (line speed). In this example, films were cut into 12"x4" pieces and subjected to atmospheric pressure plasma treatment under various conditions on rotating electrodes (one electrode moving, the other stationary). The experimental conditions and results are listed in Table 1.

[0098] The strength (maximum load) of the control porous membrane and the APMW plasma modified porous membrane is summarized in Table 1. The results showed that the modified films retained more than 70% (mostly) of their original strength and improved wettability compared to the control samples. By selecting the conditions, the strength of the modified membrane can be more than 80%, more than 90%, and more than 95% of the strength of the untreated porous membrane. Higher strength is...

Embodiment 2

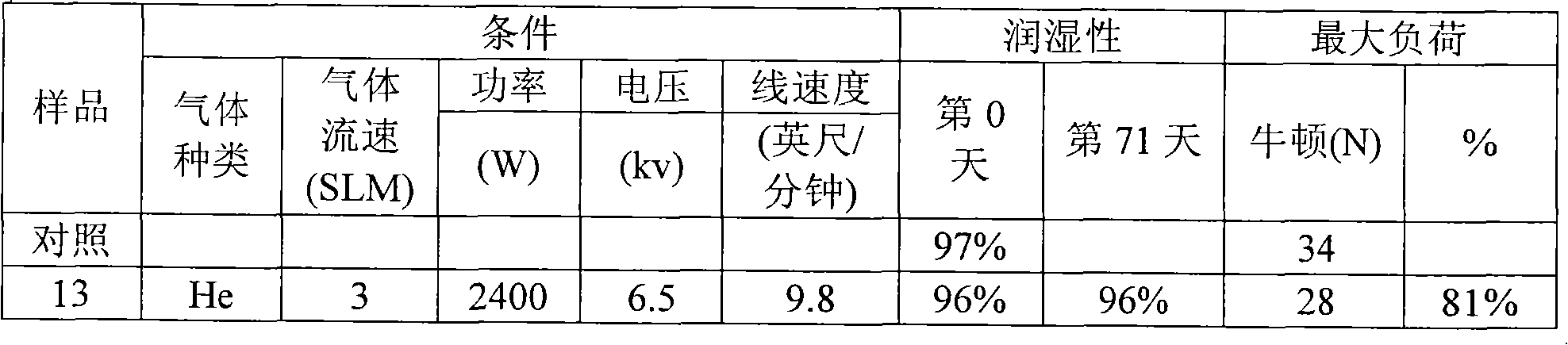

[0104] The conditions and results of the atmospheric-pressure microwave plasma treatment of a single-layer 0.05 μm PTFE porous membrane are listed in Table 2.

[0105] Table 2. APMW plasma treatment of 0.05 μm PTFE monolayer porous membrane

[0106]

[0107] Sample 13 showed improved wettability after atmospheric pressure plasma treatment and the film retained more than 80% of its strength. An untreated control sample, a pristine 0.05 micron PTFE membrane, was wettable by a MeOH solution having a MeOH concentration equal to or greater than 97% by weight. After atmospheric-pressure microwave plasma treatment, the modified membrane samples were contact-wettable by 96 wt% MeOH solution, which means better wettability. The results showed that the membrane retained its contact wettability after storage at ambient conditions for 10 days or more, and after 70 days or more. For example, APMW membranes were initially contact wetted with various solutions of MeOH and water to deter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com