Multilayer coating film-forming method

A multi-layer coating and coating technology, which can be applied to devices and coatings for coating liquid on the surface, which can solve problems such as deficiencies and achieve the effect of excellent coating processability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1-4

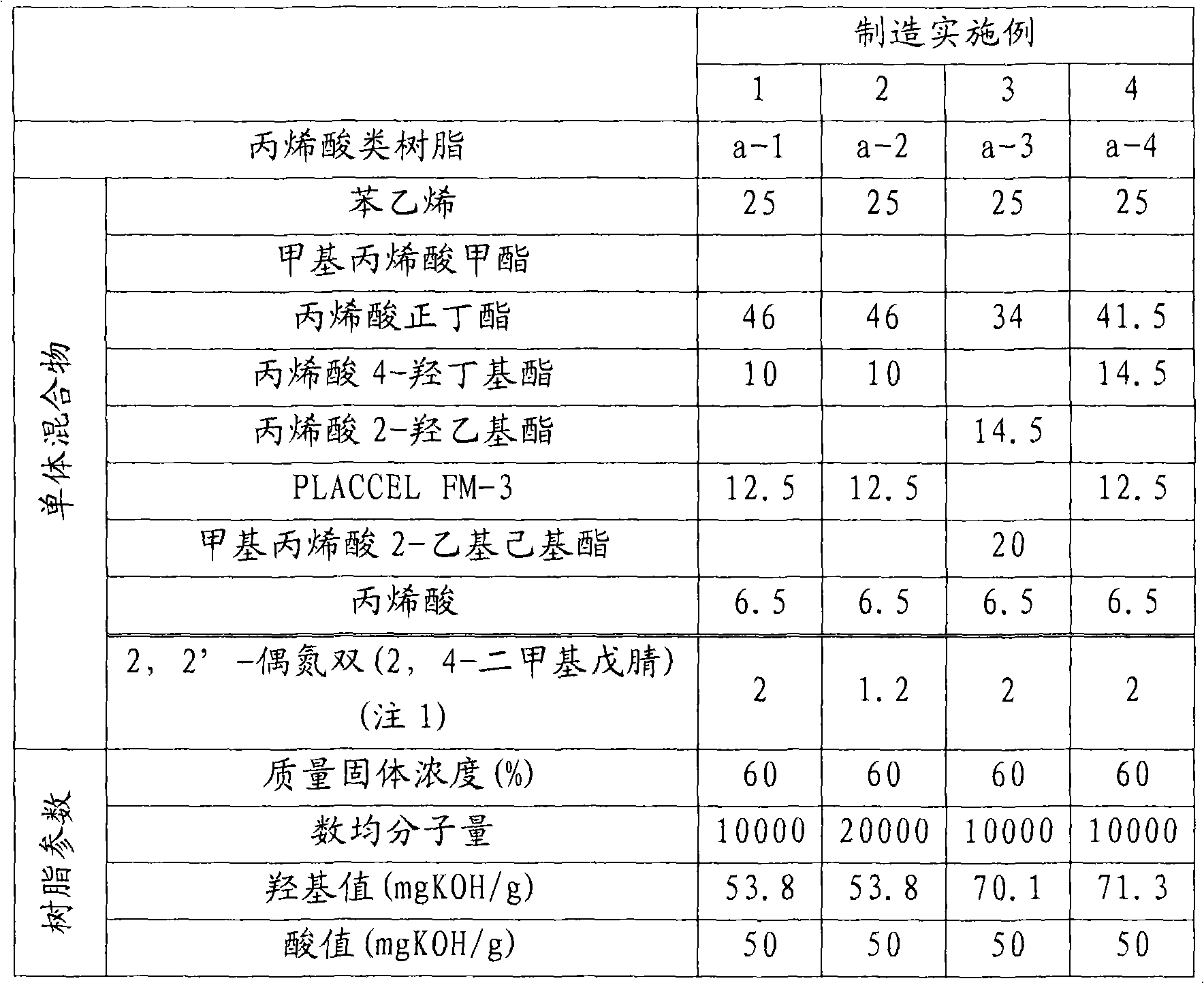

[0166] Into a four-necked flask equipped with a stirrer, a thermometer, a cooling tube, and a nitrogen inlet, 37.5 parts of isopropanol was charged, and then its temperature was raised to 85° C. under passage of nitrogen. After it reached 85° C., nitrogen supply was stopped, and each monomer mixture having the mixed composition of monomers and polymerization initiators shown in Table 1 below was added dropwise to the flask within 3 hours. (The system employed weak reflux conditions during the initial stages of the dropwise addition, but this was discontinued as the dropwise addition continued.) The reaction system was aged for an additional 2 hours at 85°C while passing nitrogen. , and cooled to 60°C. The product was diluted with 29 parts of methoxypropanol to obtain solutions of acrylic resins (a-1)-(a-4) having a solid content of 60% by mass of carboxyl groups and hydroxyl groups, respectively. The solid mass concentration (%) and resin parameters of the formed resin (a-1)-...

manufacture Embodiment 5-7

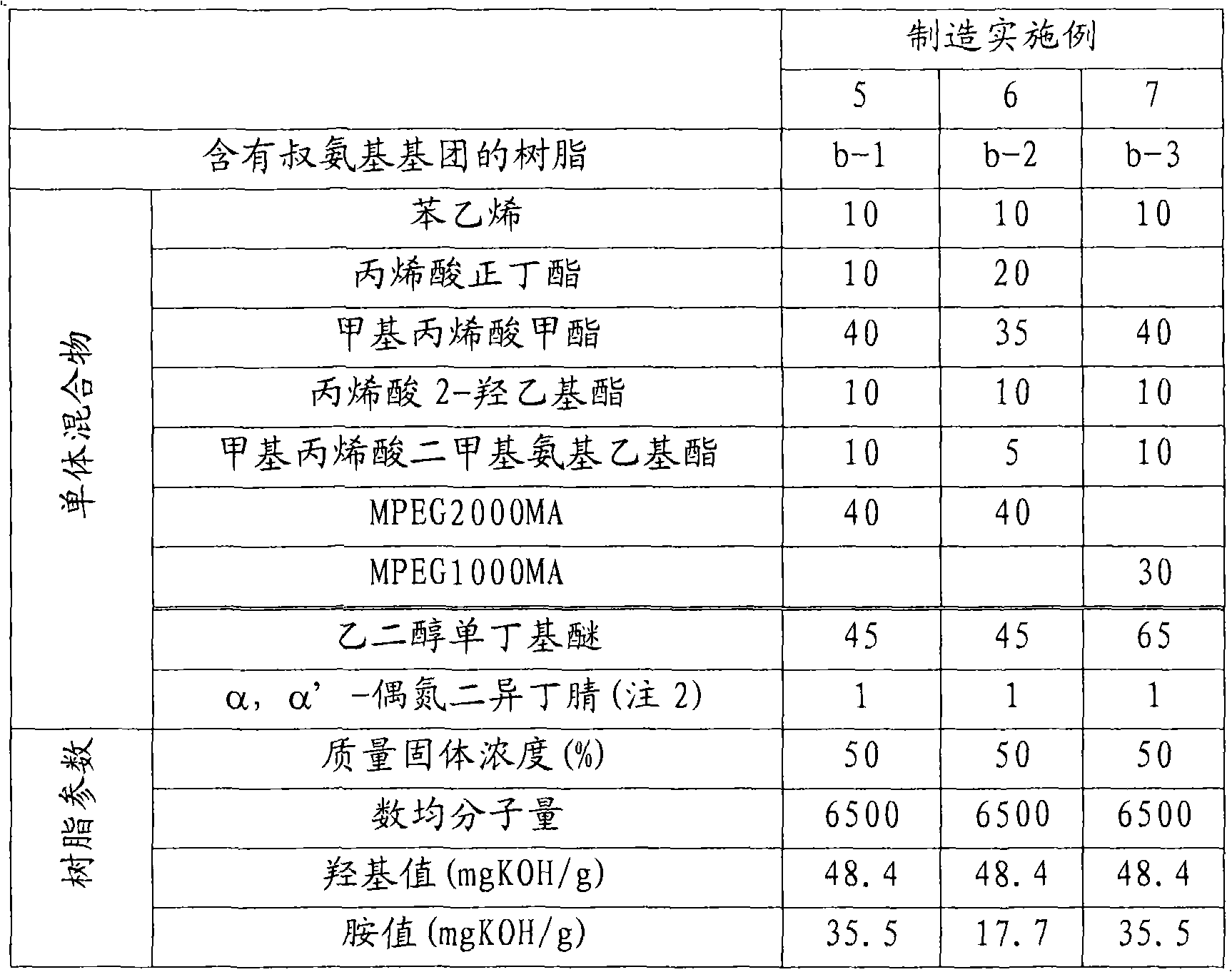

[0173] Into a four-necked flask equipped with a stirrer, a thermometer, a cooling tube and a nitrogen inlet, 20 parts of ethylene glycol monobutyl ether was charged, and its temperature was raised to 95° C. under nitrogen passage. After it reached 95° C., nitrogen supply was stopped, and each monomer mixture having the mixed composition of monomers and polymerization initiators shown in Table 2 below was added dropwise to the flask within 3 hours. Each product was then aged at 95°C for 2 hours under nitrogen passage, cooled to 60°C, and diluted with 15 parts of ethylene glycol monobutyl ether to provide tertiary amino groups with a solid content of 50% by mass. Solutions of resins (b-1)-(b-3). The solid mass concentration (%) and resin parameters of the formed resin (b-1)-(b-3) solutions are shown in Table 2 below.

[0174] In Table 2, MPEG2000MA (trade name) is a methoxypolyethylene glycol 2000 methacrylate, and MPEG 1000MA (trade name) is a methoxypolyethylene glycol 1000 m...

manufacture Embodiment 9

[0183] An aqueous dispersion of the acrylic resin (i) is produced as follows, and is used as a resin dispersion for the water-based base paint (B).

[0184] Charge 145 parts of deionized water and 1.2 parts of Newcol 562SF (Note 3) into a reactor equipped with a thermometer, automatic thermostat, stirrer, reflux condenser and dropping device, and put them in a nitrogen stream. Stir and mix. The temperature was raised to 80°C, 5% of the following total amount of monomer emulsion (1) and 5.2 parts of 3% ammonium persulfate aqueous solution were added to the reactor, and kept at 80°C for 20 minutes.

[0185] The remaining monomer emulsion (1) was then added dropwise to the reactor over 3 hours, followed by aging for 30 minutes. Then the following monomer emulsion (2) was added dropwise over 1.5 hours. The reaction mixture was aged for 2 hours and cooled to 30° C. during the gradual addition of 89 parts of a 1.5% aqueous solution of N,N-dimethylethanolamine to the reactor. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com