Photoelectric conversion element using thermosetting sealing agent for photoelectric conversion element

A technology of photoelectric conversion devices and sealants, which is applied in the direction of electrical components, photovoltaic power generation, electrolytic capacitors, etc., can solve the problems of insufficient durability evaluation, achieve high durability and reliability, excellent adhesion and moisture resistance and reliability Sexuality and low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

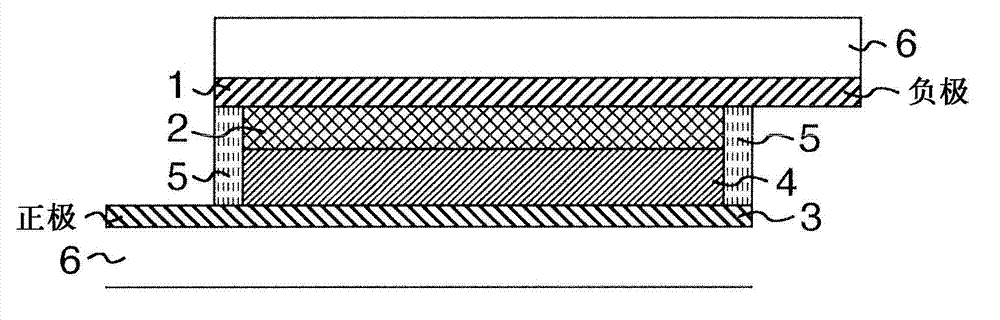

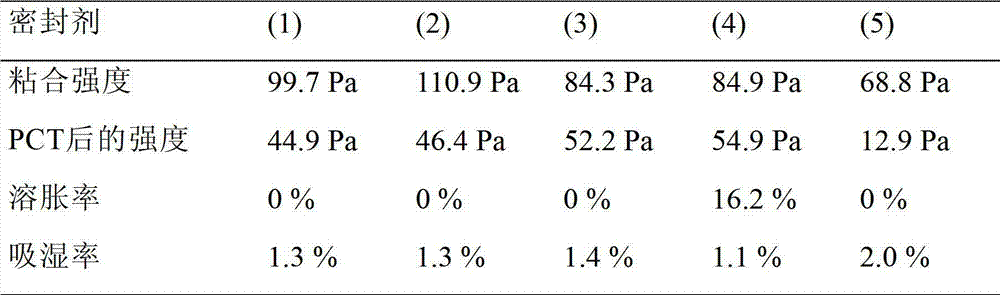

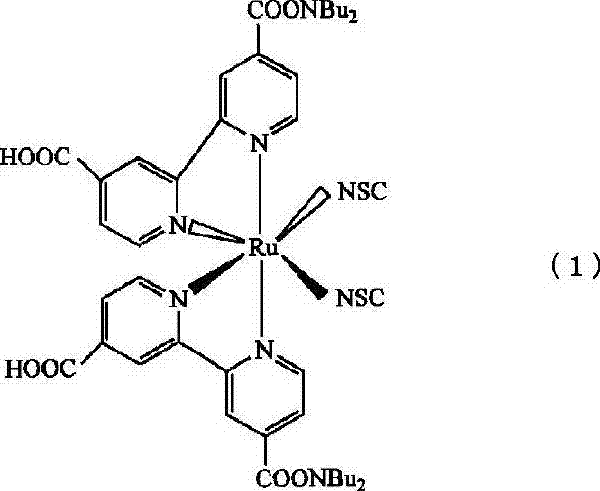

[0111] As an example of a photoelectric conversion device ( figure 1 ) shown, by screen printing machine on the conductive surface of the FTO conductive glass support as the conductive support, coated with terpineol to make paste-like TiO 2 fine particles (average particle diameter: 20 nm), and fired at 450° C. for 30 minutes to thereby form a conductive support having a semiconductor-containing layer (film thickness: 10 μm, minor axis width: 5 mm). The dye represented by formula (1) is 3.2×10 -4 The concentration of M was dissolved in a 1:1 mixed solvent of acetonitrile and tert-butanol; and the conductive support provided with the semiconductor-containing layer obtained above was immersed in a dye solution for 48 hours at room temperature to thereby fabricate an oxidized material semiconductor electrodes. Then, similarly on the conductive surface of the FTO conductive glass support with Pt was vapor-deposited to thereby fabricate a counter electrode.

[0112] [Formula 1...

Embodiment 2

[0117] A photoelectric conversion device (device 2) of the present invention was obtained in the same manner as in Example 1 except that the sealant (1) was changed to the sealant (2) in Sealant Production Example 2.

Embodiment 3

[0119] A photoelectric conversion device (device 3) of the present invention was obtained in the same manner as in Example 1 except that the sealant (1) was changed to the sealant (3) in Sealant Production Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com