Injection molded article of fiber-reinforced polylactic acid resin

A polylactic acid resin, fiber reinforced technology, applied in the direction of coating, etc., can solve the problems of impossible to obtain mechanical strength and flame retardancy, reduction of the proportion of plant-based resin, reduction of reproducibility, etc., to achieve excellent and good reproducibility. Excellent mechanical strength and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

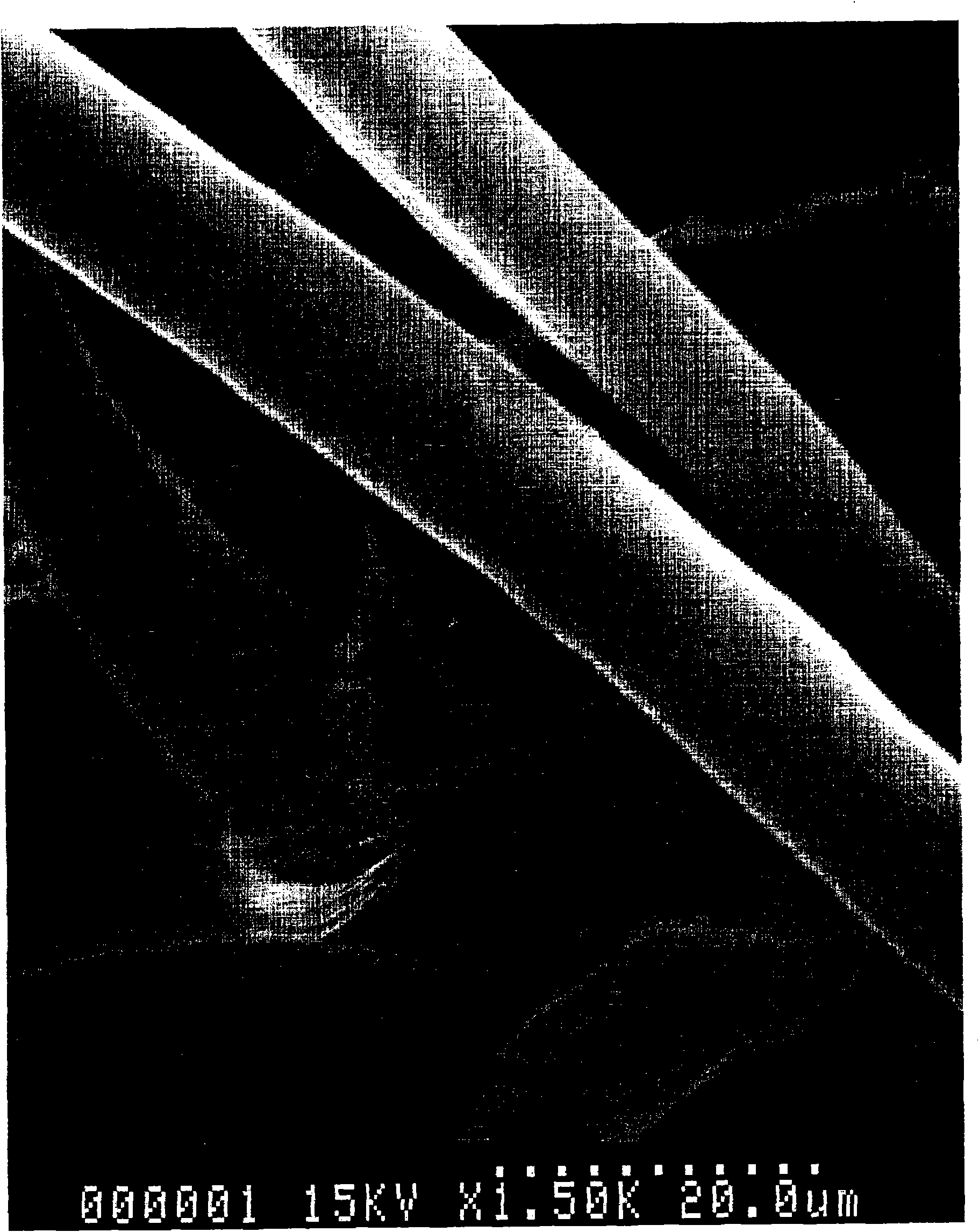

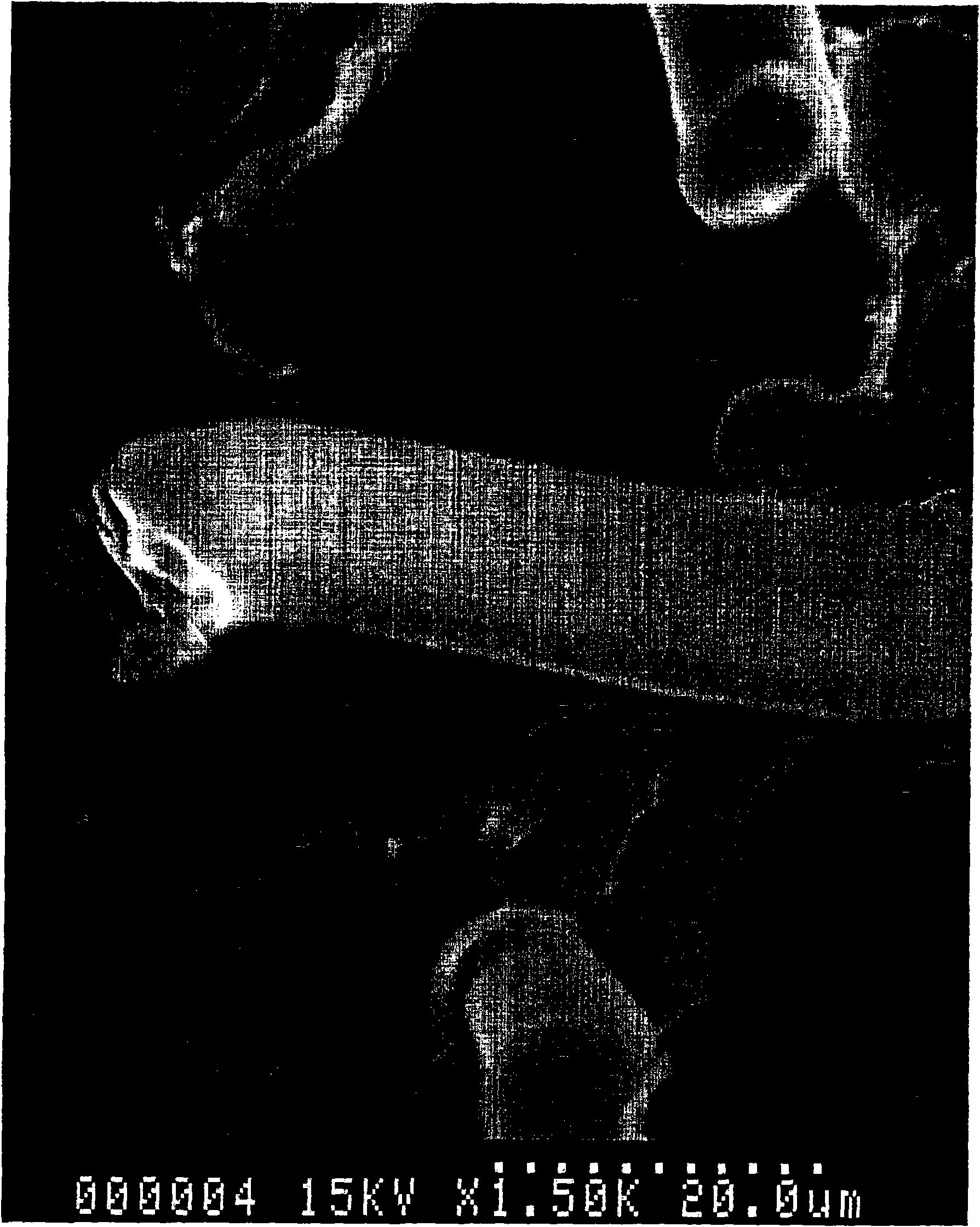

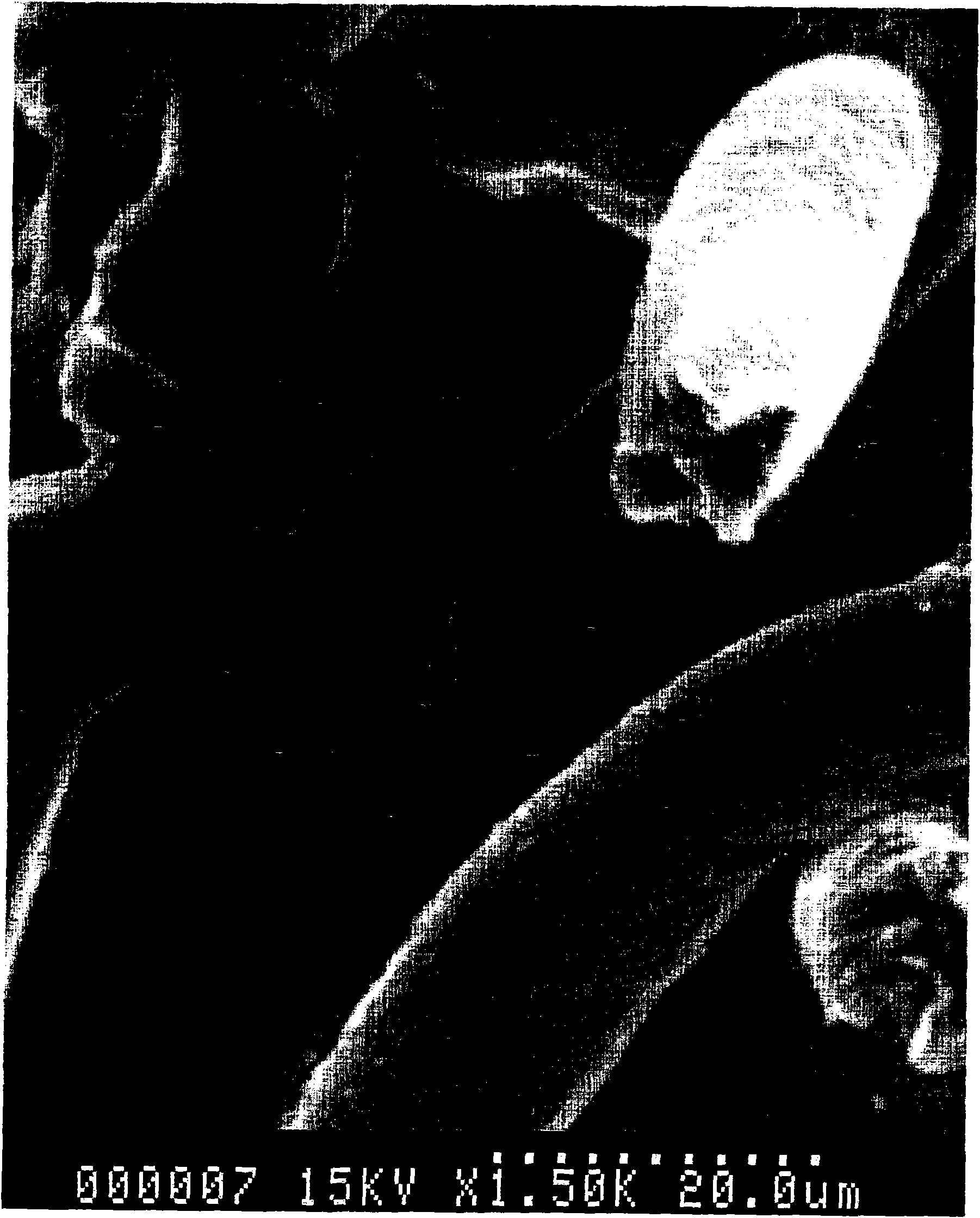

[0091] By mixing 68 parts by weight of polylactic acid (LACEA (registered trademark) (product number H-100; manufactured by Mitsui Chemicals, Inc.)), 30 parts by weight of PET (TOYOBO polyester filament yarn; cut Length (average) 7mm; fiber diameter (average) 20 μm; aspect ratio (average) 350), 2 parts by weight of TPP (manufactured by DAIHACHI CHEMICALINDUSTRY CO., LTD) as a monomer phosphoric acid ester to prepare the resin composition, and detect The mixing and molding temperature of the composition is determined. The results are listed in Table 1. The mixing and molding temperature is defined as the temperature at which the viscosity of the heated composition is 10 to 100 Pa·s. In Table 1, the addition rate refers to the ratio of the weight of monomeric phosphoric acid ester to the total weight of the resin composition.

Embodiment 2

[0093] By mixing 83 parts by weight of polylactic acid, 15 parts by weight of PPS (TORCON (registered trademark); manufactured by Toray Industries, Inc.; cut length (average) 7 mm; fiber diameter (average) 20 μm; aspect ratio (average) 350), 2 parts by weight of TPP as a monomeric phosphate ester to prepare a resin composition, and as in Example 1, the mixing and molding temperature of the composition were checked. The results are listed in Table 1.

Embodiment 3

[0095] By mixing 88 parts by weight of polylactic acid, 10 parts by weight of PI (P84, manufactured by TOYOBO CO., LTD. as reinforcing fibers; cut length (average) 7 mm; fiber diameter (average) 20 μm; aspect ratio (average) 350), 2 parts by weight of TPP as a monomeric phosphoric acid ester to prepare a resin composition, and detect the mixing and molding temperature of the composition as in Example 1. The results are listed in Table 1.

[0096] Table 1

[0097]

[0098] As shown in Table 1, the addition of the monomeric phosphates allowed the mixing temperature of each resin composition to be at least 50°C below the melting point of the reinforcing fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com