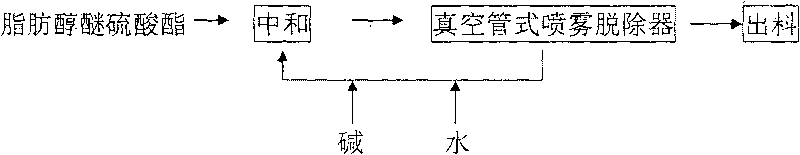

Technology for producing fatty alcohol polyethyleneglycol ether sulfate with low dioxane content by continuous vacuum tube type neutralization

An alcohol polyoxyethylene ether, vacuum tube type technology, applied in the direction of sulfuric acid ester preparation, transportation and packaging, chemical instruments and methods, etc., can solve the problems of poor system stability, increased energy consumption waste, large equipment investment, etc., to achieve easy system , stable operation, and the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

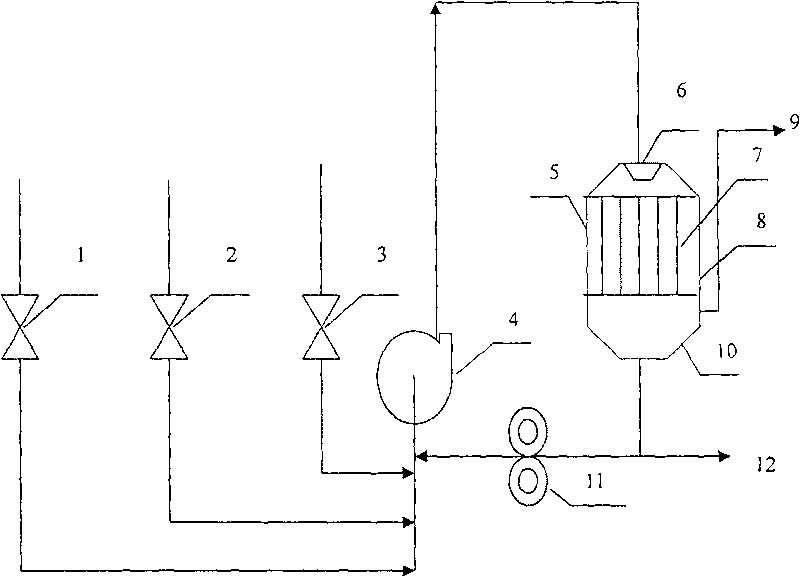

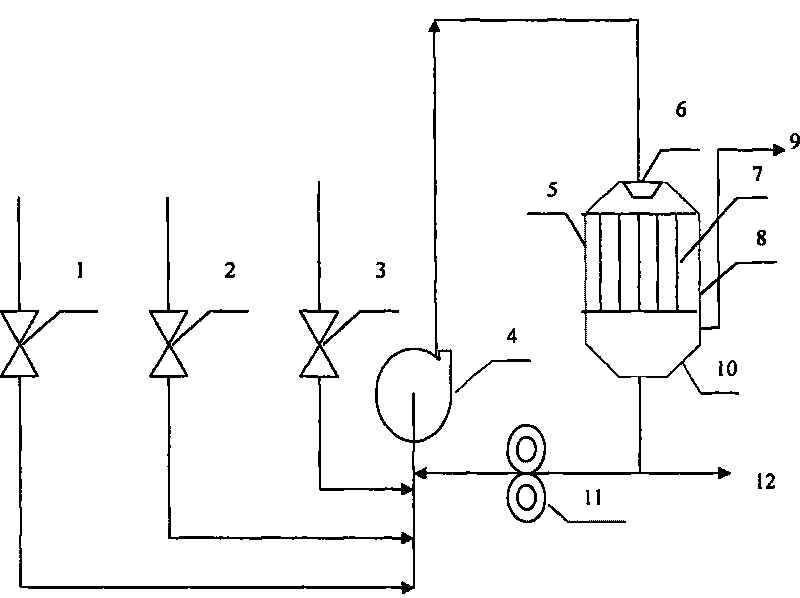

Method used

Image

Examples

Embodiment 1

[0032]The fatty alcohol ether sulfate that passes through the gas-liquid separator enters the neutralizer at a temperature of 43°C at a flow rate of 1200kg / h, and the circulating material enters the neutralizer at a flow rate of 36400kg / h together with liquid caustic soda and water measured by a flowmeter , the mixing and neutralization is completed in the neutralizer, the temperature is 65 ° C; the neutralized material enters the material distribution chamber on the upper part of the vacuum tube spray remover, and is atomized through the nozzle and sent to the vacuum removal tube, and the vacuum removal tube The outer jacket is kept warm with 60°C hot water, and the vacuum degree of the vacuum removal tube is controlled: 0.085MPa. The material forms an atomized turbulent state in the vacuum removal tube; 1,4-dioxane in the material forms an azeotrope with water After the condensate is evaporated and removed from the system in gaseous form, it is collected in the condenser of t...

Embodiment 2

[0034] The fatty alcohol ether sulfate that passes through the gas-liquid separator enters the neutralizer at a temperature of 45°C at a flow rate of 3000kg / h, and the circulating material enters the neutralizer at a flow rate of 30000kg / h together with ammonia water and water measured by the flowmeter. Mixing and neutralization is completed in the neutralizer, the temperature is 70°C; the neutralized material enters the material distribution chamber on the upper part of the vacuum tube spray remover, and is atomized and sent to the vacuum removal tube through the nozzle, and the vacuum removal tube The jacket is kept warm with hot water at 70°C, and the vacuum degree of the vacuum removal tube is controlled: 0.095MPa. The material is atomized in the vacuum removal tube to form a turbulent state; under vacuum conditions, 1,4-dioxane in the material and water form After the azeotrope is evaporated from the system in gaseous form, it is collected in the condenser of the vacuum sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com