Method for controlling electronic power steering system of vehicle without sensor

A technology of electric power steering and steering system, applied in the direction of automatic steering control components, electric steering mechanism, steering mechanism, etc., can solve the problems of increasing output noise, affecting the driver's sense of road and control stability, etc., to achieve simplified structure, Eliminate the need for installation and debugging, and eliminate the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

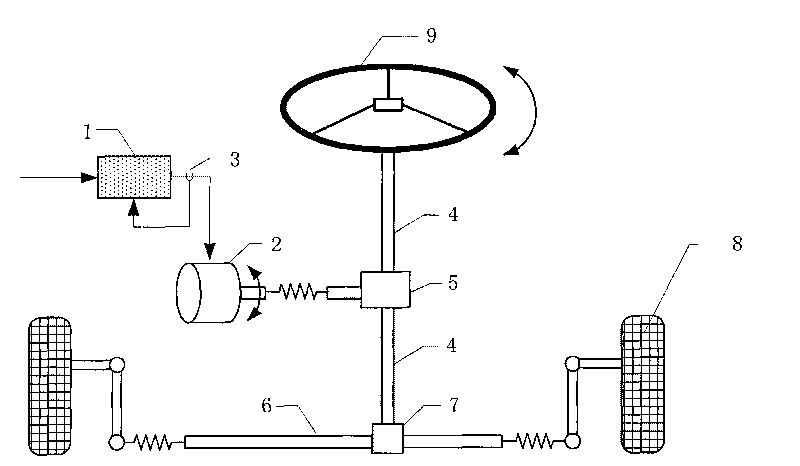

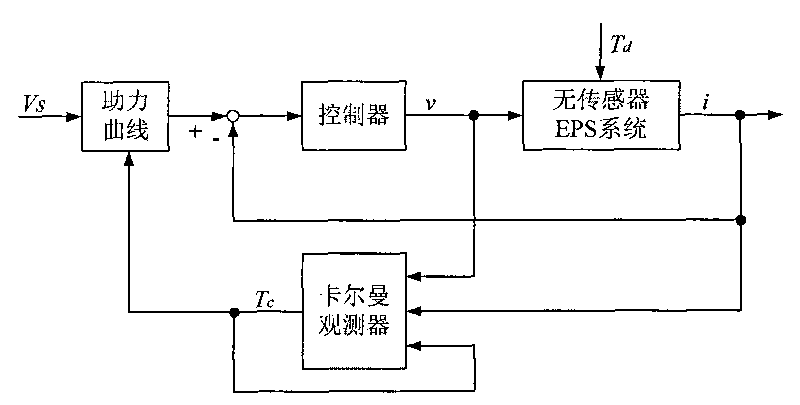

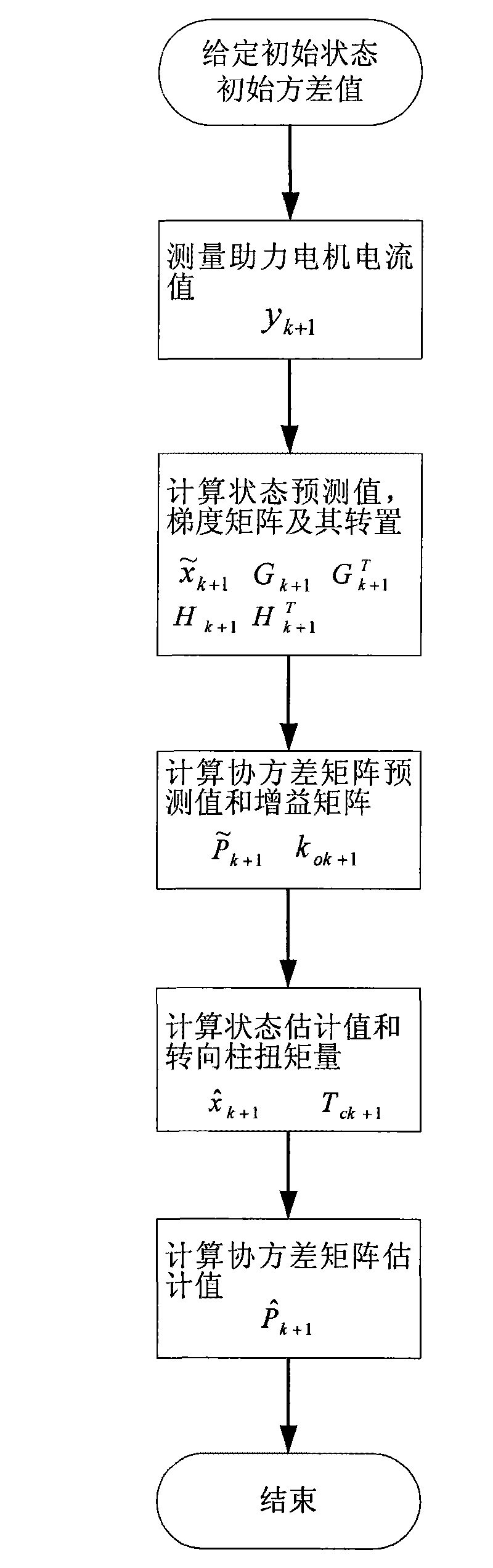

[0013] Such as figure 1 As shown, a control method of a sensorless automobile electric power steering system, the steering system includes a control unit (ECU) 1 and a booster motor 2; The state-space mathematical model executes the Kalman observer algorithm; the steering system also includes a booster motor current sensor 3, which takes the system state component of the booster motor current as the measurement input of the control unit (ECU) 1, and observes Steering column angle θ c , motor rotor angle θ m and other system state components such as rack displacement p, by formula (K c is the steering column stiffness coefficient, r p is the pinion radius) to get the steering column torque T c , thus establishing a sensorless EPS closed-loop control system to control the assist torque of the motor.

[0014] Among the figure, 4 is a steering column, 5 is a clutch and a reduction mechanism, 6 is a rack, 7 is a pinion, 8 is a wheel, and 9 is a steering wheel.

[0015] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com