Preservative film padded with minerals and preparation method thereof

A fresh-keeping film and mineral technology, applied to flexible coverings, containers, sacks, etc., can solve the problems of perishable and aging fruits and vegetables, inappropriate air ratio, poor moisture permeability, etc., achieve good fresh-keeping effect, good moisture permeability, The effect of keeping fresh for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

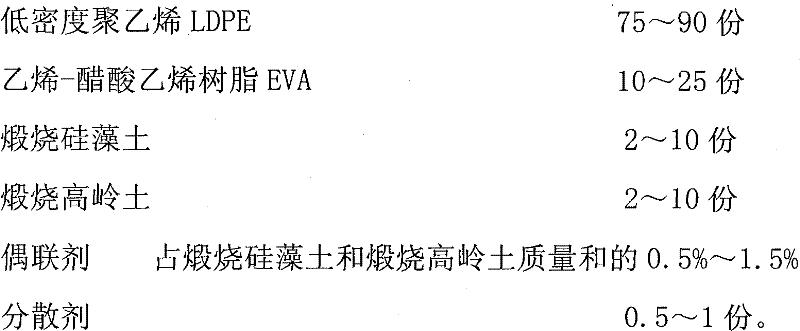

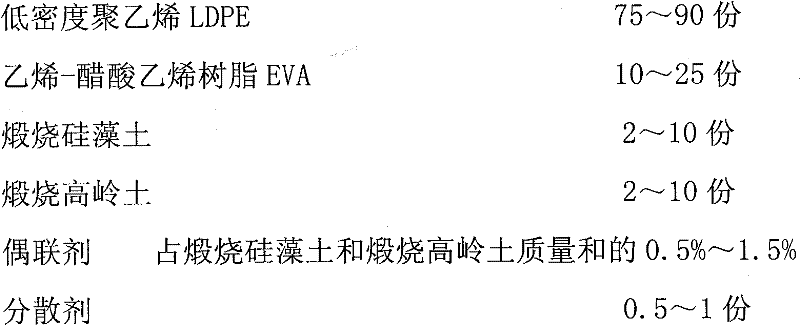

Method used

Image

Examples

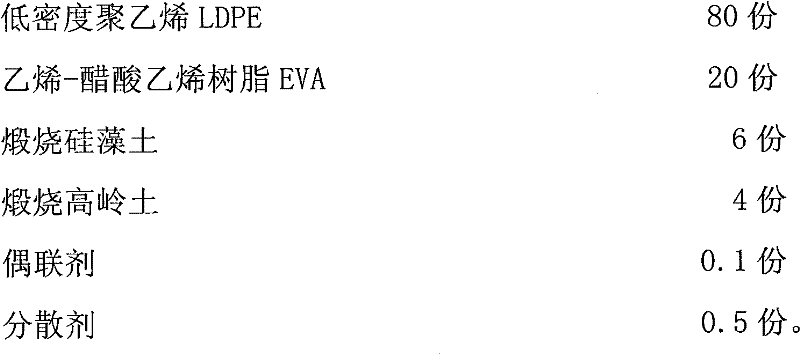

Embodiment 1

[0050] (1) Weigh 6 kg of calcined diatomite and 4 kg of calcined kaolin, respectively, and put them into a muffle furnace for calcination respectively. Diatomite is calcined at 700°C for 6 hours, and kaolin is calcined at 850°C for 6 hours to obtain calcined diatom Soil and calcined kaolin;

[0051] (2) Put the above-mentioned calcined diatomite and calcined kaolin into a high-speed kneader, heat to 90-100°C and start stirring, add 0.1 kg of silane coupling agent KH-550, and stir at 90-100°C for 5-10 minutes , drying after discharge to obtain activated composite filler;

[0052] (3) Add 80 kg of low-density polyethylene (LDPE), 20 kg of ethylene-vinyl acetate resin (EVA), and 0.5 kg of stearic acid to the obtained composite filler, and mix all the ingredients evenly with a plastic particle mixer , pelletized on a twin-screw extruder at a temperature of 105°C to 140°C, and then blown into a 30um film by a single-screw extrusion blow molding machine at a temperature of 120°C to...

Embodiment 2

[0054] (1) Weigh 2 kg of calcined diatomite and 10 kg of calcined kaolin, respectively, and put them into a muffle furnace for calcination respectively. Diatomite is calcined at 700°C for 6 hours, and kaolin is calcined at 850°C for 6 hours to obtain calcined diatom Soil and calcined kaolin;

[0055] (2) Put the above-mentioned calcined diatomite and calcined kaolin into a high-speed kneader, heat to 90-100°C and start stirring, add 0.12 kg of silane coupling agent KH-560, and stir at 90-100°C for 5-10 minutes , drying after discharge to obtain activated composite filler;

[0056] (3) 75 kilograms of low-density polyethylene (LDPE), 25 kilograms of ethylene-vinyl acetate resin (EVA), 0.5 kilogram of paraffin, join in the composite filler that obtains, after all ingredients are mixed evenly through plastic particle mixer, in It is pelletized on a twin-screw extruder at a temperature of 105°C to 140°C, and then blown into a 30um film by a single-screw extrusion blow molding mac...

Embodiment 3

[0058](1) Weigh 10 kg of calcined diatomite and 2 kg of calcined kaolin, respectively, and put them into a muffle furnace for calcination respectively. Diatomite is calcined at 700°C for 6 hours, and kaolin is calcined at 850°C for 6 hours to obtain calcined diatom Soil and calcined kaolin;

[0059] (2) Put the above-mentioned calcined diatomite and calcined kaolin into a high-speed kneader, heat to 90-100°C and start stirring, add 0.06 kg of silane coupling agent KH-570, and stir at 90-100°C for 5-10 minutes , drying after discharge to obtain activated composite filler;

[0060] (3) Add 90 kg of low-density polyethylene (LDPE), 10 kg of ethylene-vinyl acetate resin (EVA), and 0.5 kg of polyethylene wax to the obtained composite filler, and mix all the ingredients evenly with a plastic particle mixer , pelletized on a twin-screw extruder at a temperature of 105°C to 140°C, and then blown into a 30um film by a single-screw extrusion blow molding machine at a temperature of 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com