Heavy paraffin oil solvent deasphalting process for reducing recycle ratio of coking unit

A technology of coking equipment and heavy wax oil, which is applied in the petroleum industry and processing hydrocarbon oil, etc. It can solve the problems of high fuel consumption of heating furnace, low load utilization rate, and reduced processing volume, so as to reduce floor space and equipment investment , the effect of reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

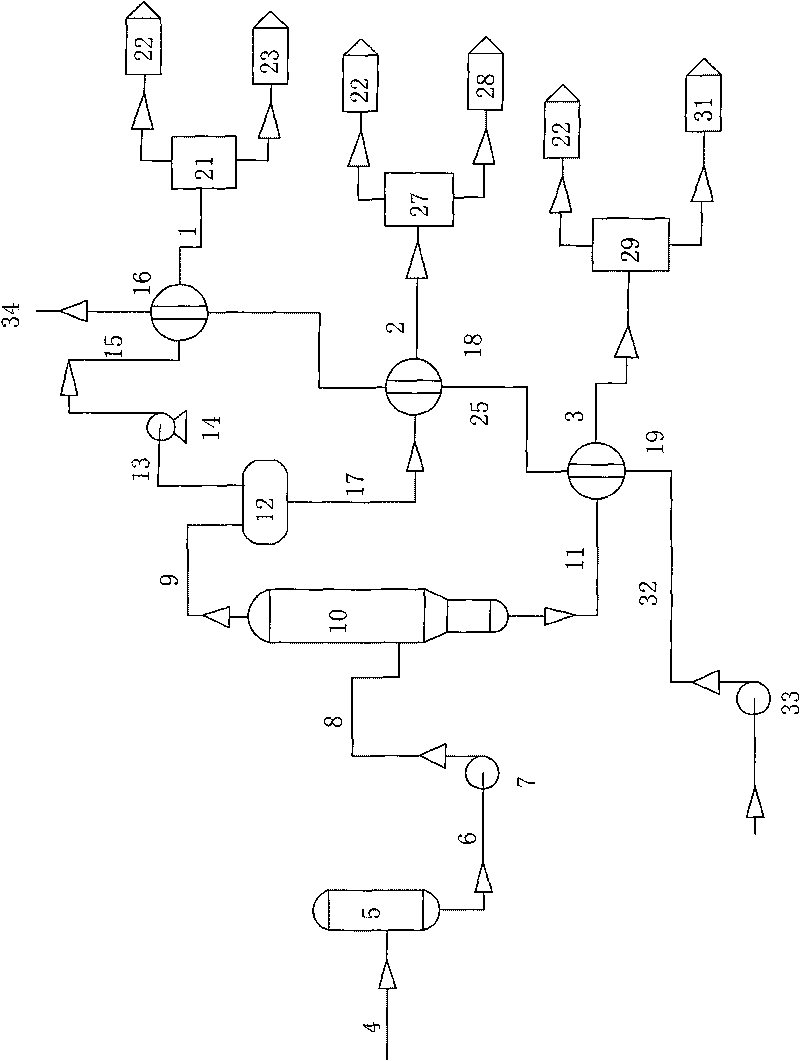

[0072] This embodiment is the two-stage extraction process of thermal combination method, such as figure 1 shown.

[0073] (1) After the heavy wax oil of the first, second and third sets of coking units in the refinery merges, it enters the raw material buffer tank 5 of the solvent deasphalting unit parasitic in the coking unit through the pipeline 4, and then flows through the pipeline 6 into the raw material pump 7. Mix with solvent after pressurization, the temperature is about 152°C, enter the extractor 10 through the pipeline 8, and after solvent extraction, the heavy wax oil is divided into two phases: the discharge from the top pipeline 9 of the extractor 10 contains desorbed A stage of extracting liquid of asphalt oil, colloid and most of the solvents; what is discharged from the lower pipeline 11 of the extractor is deoiled asphalt and a raffinate containing a small amount of solvents.

[0074] (2), one section of extract enters colloid settler 12 after heat exchanger ...

Embodiment 2

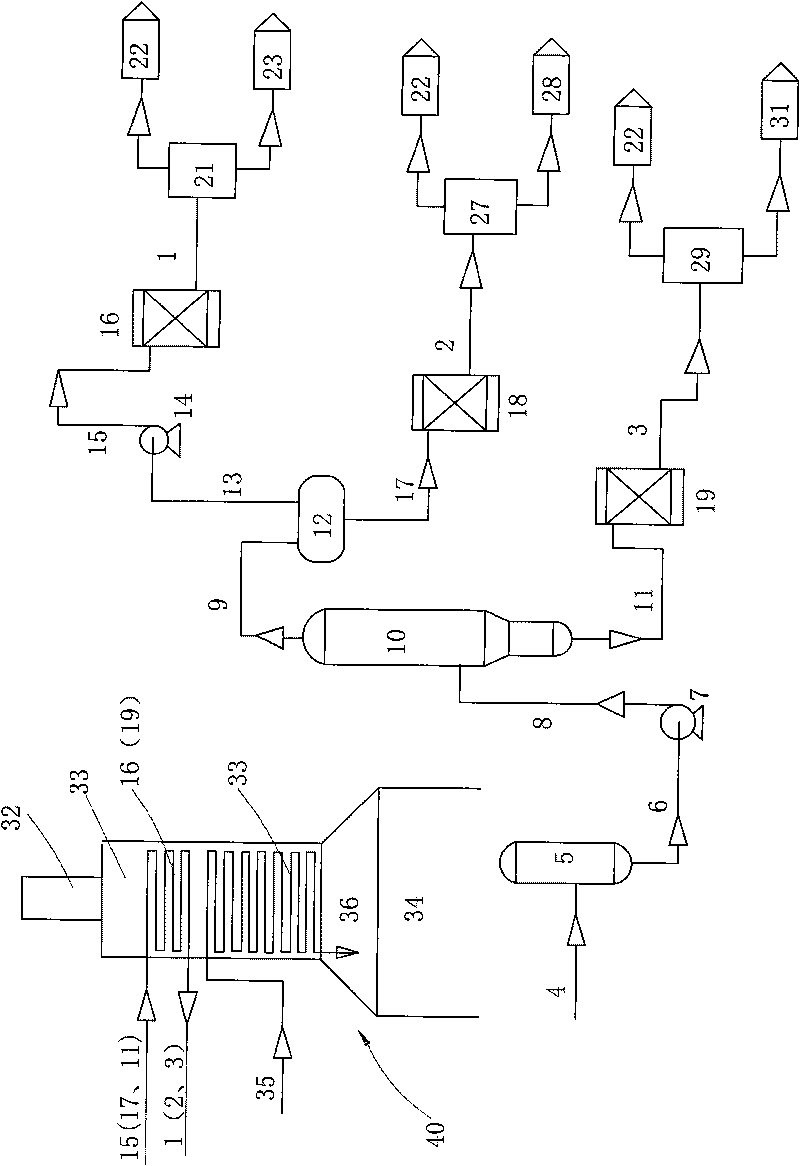

[0083] This embodiment is a two-stage extraction process of sharing the heating furnace of the coking unit.

[0084] (1) After the heavy wax oil of the first, second and third sets of coking units in the refinery merges, it enters the raw material buffer tank 5 of the solvent deasphalting unit parasitic in the coking unit through the pipeline 4, and then flows through the pipeline 6 into the raw material pump 7. Mix with solvent after pressurization. At this time, the temperature is about 152°C. After entering the extractor 10 through the pipeline 8 and being extracted by solvent, the heavy wax oil is divided into two phases: what is discharged from the pipeline 9 at the top of the extractor 10 is A section of extract containing deasphalted oil, colloid and most of the solvent; the discharge from the lower pipeline 11 of the extractor is deoiled asphalt and a raffinate containing a small amount of solvent.

[0085] (2), one section of extract enters colloid settler 12 after he...

Embodiment 3

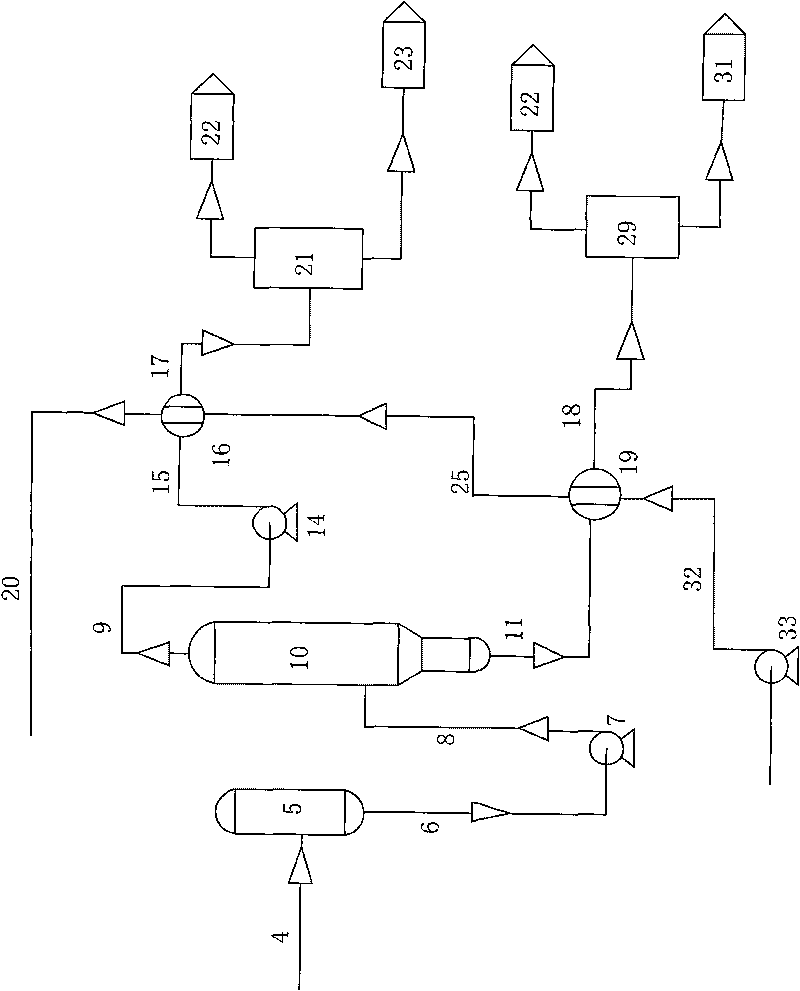

[0095] This embodiment is a one-stage extraction process of thermal combination method, such as image 3 shown.

[0096] (1) After the heavy wax oil of the first, second and third sets of coking units in the refinery merges, it enters the raw material buffer tank 5 of the solvent deasphalting unit parasitic in the coking unit through the pipeline 4, and then flows through the pipeline 6 into the raw material pump 7. Mix with solvent after pressurization. At this time, the temperature is about 152°C. After entering the extractor 10 through the pipeline 8 and being extracted by solvent, the heavy wax oil is divided into two phases: what is discharged from the pipeline 9 at the top of the extractor 10 is A section of extract containing deasphalted oil and most of the solvent; the discharge from the lower line 11 of the extractor is deoiled asphalt and a raffinate containing a small amount of solvent.

[0097] (2), one section of extract enters the booster pump 14 after exchangin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com