Composite square material used in building operations

A technology for building construction and compounding, which is applied in the on-site preparation of building components, construction, building construction, etc., can solve problems such as deformation and cracking of square wood, affecting the quality of structural molding, reduce construction costs, and benefit forest resources. Protective, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

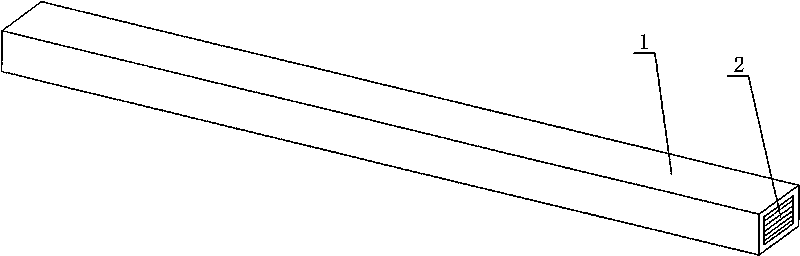

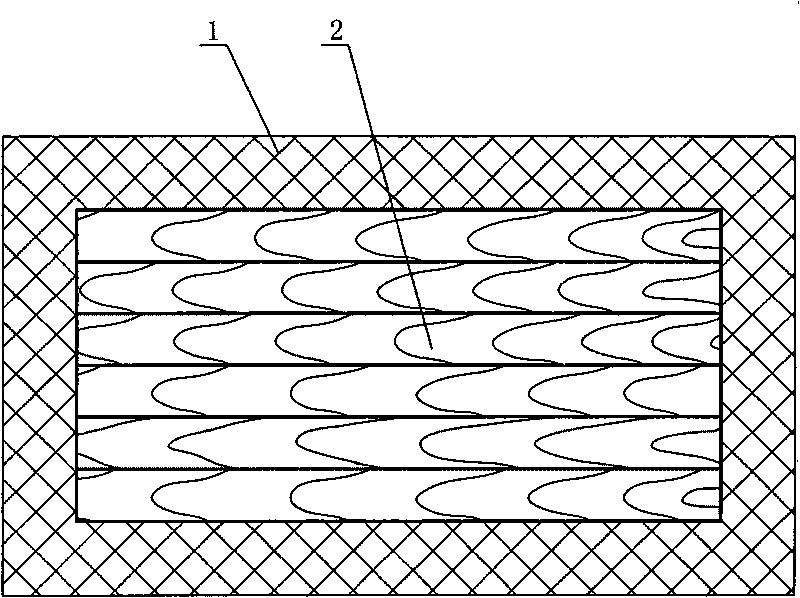

[0016] A composite square material used in building construction, comprising a plastic outer shell 1 and a multi-layer support body 2, the multi-layer support body 2 is fixedly arranged in the plastic outer shell 1, and the plastic outer shell 1 and the multi-layer support body 2 is a one-shot integral structure.

[0017] A composite beam manufacturing method used in building construction is:

[0018] Dry the recycled waste plastic products to remove water. Then, the waste wood products are processed into wood fibers with a length of 20 mm and a diameter of 1 mm. Mix the above two raw materials with 80% waste plastics and 20% wood fiber (the above percentages are percentages by weight), put them into a container and heat them to 180°C to melt, and then make plastic strips, and the temperature is controlled at 130°C . A plurality of waste plywoods are made into strips respectively, and the plurality of waste plywoods are glued and connected in sequence. The two plastic stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com