Method for preparing compound flocculating agent

A flocculant and composite technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the difficulty of large-scale industrial production and use of microbial flocculants, reduce the total amount of flocculants, the residual amount of metal ions, flocculant molecules Problems such as different structures, to achieve the effect of weakening secondary pollution, good promotion value, and good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

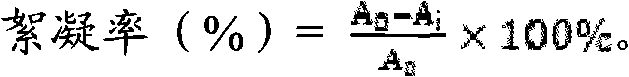

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of biological flocculant solution: mix EM, honey, and sterile water in a volume ratio of 5:5:90, and ferment for 3 days at 25°C with a rotary shaker speed of 120r / min to obtain EM Fermentation liquid: Centrifuge the fermentation liquid at a speed of 8000r / min for 20 minutes, evaporate and concentrate the separated liquid to 1 / 4 of the original volume at 40°C-50°C, cool to 4°C, add 2 times the volume of anhydrous cold ethanol , placed at 4°C for 24 hours, poured out the liquid, and retained the flocculation sedimentation substrate; then added ethanol with an equal volume of 80% mass concentration to the separated liquid part, left it for 24 hours, poured out the liquid part, and retained the flocculation sediment Precipitate, repeat this step twice to collect the flocculated precipitate; then dilute the precipitate with ethanol and dry it under vacuum for 6-8 hours under the condition of 10-12pa to obtain the solid bio-flocculant; dissolve the bio-floccula...

Embodiment 2

[0028]The difference between this implementation and Example 1 is: EM, honey, and sterile water are mixed according to the volume ratio of 5:5:90 and then fermented in a sealed container for 3 days. The other steps and parameters are the same as in Example 1. Composite flocculants are also available.

Embodiment 3

[0030] (1) Preparation of biological flocculant solution: mix EM, honey, and sterile water evenly according to the volume ratio of 5:5:90, and ferment for 3 days at 25°C with a rotary shaker speed of 120r / min; use 5000r Centrifuge the fermented liquid at a speed of 1 / min for 20 minutes, evaporate and concentrate the separated liquid to 1 / 4 of the original volume at 40°C to 50°C, cool it down to 4°C, add 2 times the volume of anhydrous cold ethanol, and cool it at 4°C Put it under the ground for 24 hours, pour out the liquid, keep the flocculation sedimentation substrate; then add ethanol with an equal volume mass concentration of 80% to the separated liquid part, let it stand for 24 hours, pour out the liquid part, keep the flocculation sedimentation, repeat the process Step 2 times, collect the flocculated precipitate; then dilute the precipitate with ethanol, and dry it under vacuum for 6-8 hours under the condition of 10-12pa to obtain the solid bio-flocculant; dissolve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com