A kind of production method of flocculating water purifying agent containing silicon and aluminum humate

A humate and production method technology, applied in flocculation/sedimentation water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of secondary environmental damage and non-recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

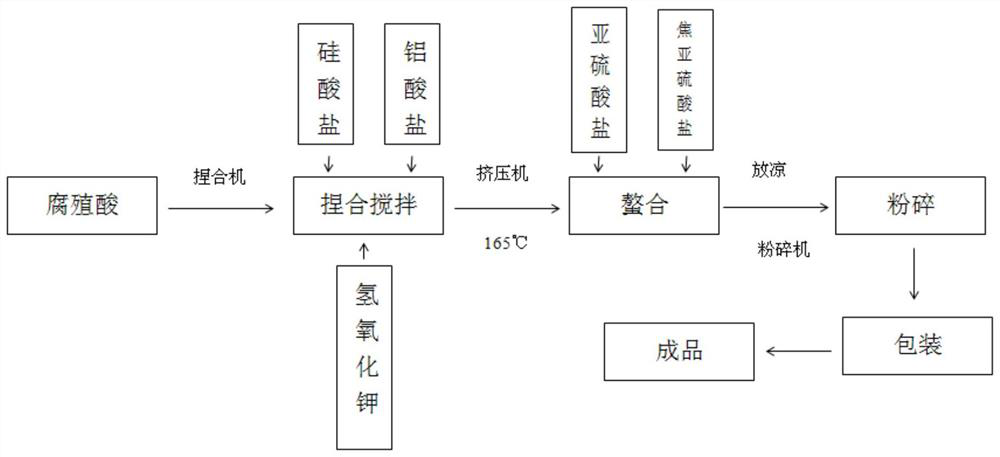

Method used

Image

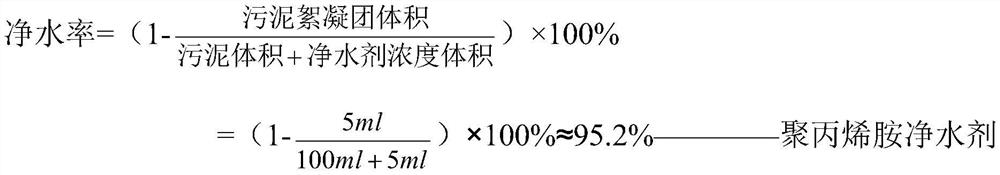

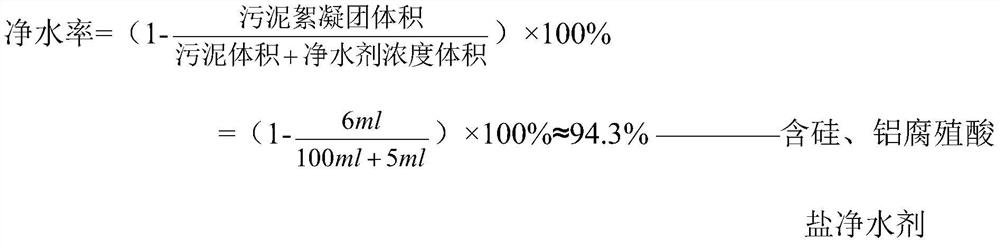

Examples

Embodiment 1

[0025] Put 100kg of humic acid on a dry basis into the kneader, add 50kg of water, knead and stir evenly, continue to knead and stir while adding 10kg of sodium silicate, 10kg of sodium aluminate, and 5kg of potassium hydroxide, continue kneading and stirring for 30 minutes, and then add coke Sodium sulfite 5kg, sodium bisulfite 5kg, continue kneading and stirring for 30 minutes, put the mixture into the screw extruder, adjust the temperature to 150°C to form irregular strips, cool naturally, and pulverize the finished silicon and aluminum humate flocculation water purifier.

Embodiment 2

[0027] Put 100kg of humic acid on a dry basis into the kneader, add 50kg of water, knead and stir evenly, continue to knead and stir while adding 15kg of sodium silicate, 5kg of sodium aluminate, and 10kg of potassium hydroxide, continue kneading and stirring for 30 minutes, and then add coke Sodium sulfite 5kg, sodium bisulfite 5kg, continue kneading and stirring for 30 minutes, put the mixture into the screw extruder, adjust the temperature to 180°C to form irregular strips, cool naturally, and pulverize the finished silicon and aluminum humate flocculation water purifier.

Embodiment 3

[0029] Put 100kg of humic acid on a dry basis into the kneader, add 50kg of water, knead and stir evenly, continue kneading and stirring while adding 12kg of sodium silicate, 8kg of sodium aluminate, and 8kg of potassium hydroxide, continue kneading and stirring for 30 minutes, and then add coke Sodium sulfite 5kg, sodium bisulfite 5kg, continue kneading and stirring for 30 minutes, put the mixture into a screw extruder, adjust the temperature to 165°C to form irregular strips, cool naturally, pulverize with a pulverizer, pack, and obtain finished silicon and aluminum Humate flocculating water purifier.

[0030] The silicon, aluminum humate flocculation water purifying agent product index that the present invention obtains:

[0031] a. Water-soluble organic matter ≥ 70%;

[0032] b. Water insoluble ≤ 3%

[0033] c. Water-soluble silicon mass fraction (on a dry basis) ≥ 2%

[0034] d. Water-soluble aluminum mass fraction (on a dry basis) ≥ 3%

[0035] e. Moisture ≤ 20%

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com