Protective coating for surface of steel workpiece

A workpiece surface, protective technology, applied in the direction of alkali metal silicate coating, coating, etc., can solve the problems of short overall life, carbon atom reduction, wear resistance reduction, etc., to achieve long production cycle and prevent high temperature oxidation of the surface , The effect of improving the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

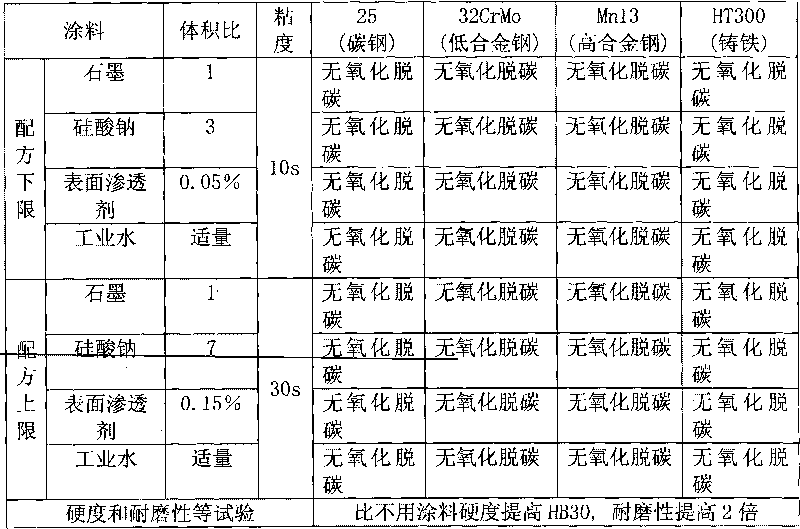

Examples

Embodiment Construction

[0013] The present invention is a water-based coating composed of graphite and a high-temperature binder, which is applied on the entire surface (partial) or protective part of a steel workpiece to form a high-strength, dense protective layer at high temperature; thereby shielding its surface from being oxidized, And make the carbon atoms in the paint diffuse to the workpiece surface (matrix) structure, and finally realize the protective coating that prevents surface high-temperature oxidation and decarburization, improves hardness and wear resistance, and improves the overall life of steel workpieces. The basic process of coating preparation, application and heat treatment is as follows:

[0014] Component preparation————————————————————————————————————————————————————————————————— → coating surface of steel workpiece———————————— → coating self-stripping

[0015] Among the components of the coating: graphite as aggregate, water glass (sodium silicate) as high temperature bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com