High-power LED lamp effectively lowering packaging thermal resistance

An LED lamp, high-power technology, applied in the cooling/heating device, lighting device, lighting and heating equipment of lighting devices, etc., can solve the problems of weakened heat conduction effect and LED device luminous failure, so as to ensure the efficacy and service life, Increase heat sink thickness and reduce the effect of thermal mismatch stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

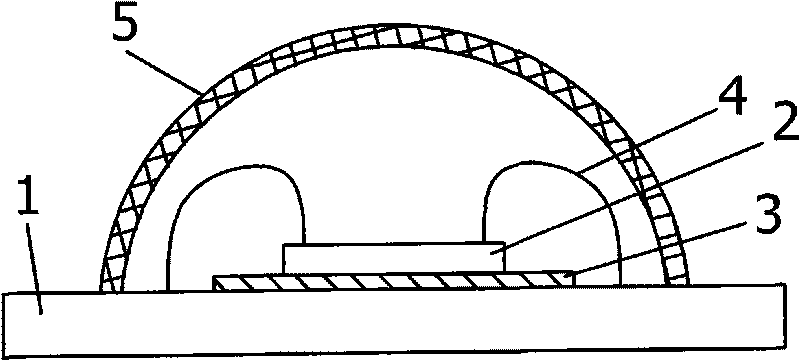

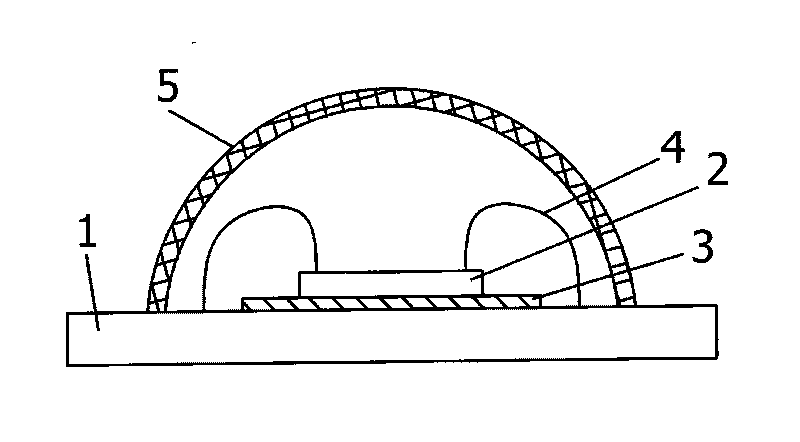

[0013] Such as figure 1 The shown high-power LED lamp effectively reduces the heat resistance of the package, including a metal base 1, an LED chip 2 packaged on the metal base 1, a metal wire 4, and an encapsulation compound 5, and the metal base 1 and the LED chip 2 is provided with a heat sink buffer layer 3 for buffering the thermal mismatch stress between the LED chip and the metal base.

[0014] The heat sink buffer layer 3 is a FeNi alloy layer electroplated on the metal base 1 .

[0015] The thickness of the FeNi alloy layer is 2-5 microns.

[0016] The FeNi alloy layer contained 36% Ni.

[0017] The LED chip 2 is connected to the heat sink buffer layer 3 by eutectic welding.

[0018] The metal base 1 is made of copper with better thermal conductivity.

[0019] The present invention is not limited to the above-mentioned best implementation mode, anyone can draw other various forms of products under the enlightenment of the present invention, but no matter make any ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com