Surface bioactive calcium-phosphate layer of carbon fiber reinforced polyetheretherketone composite material and preparation thereof

A technology of bioactive calcium and composite materials, which is applied in the field of bioactive calcium phosphorus layer and preparation on the surface of three-dimensional woven carbon fiber reinforced polyether ether ketone composite materials, can solve the problems of high application value and achieve improved biological level and good therapeutic effect , good surface bioactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

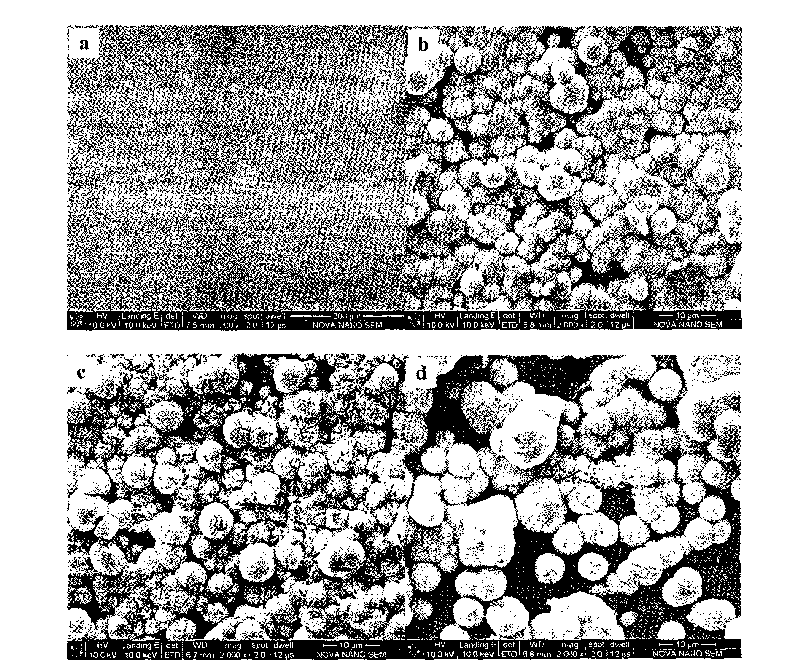

Image

Examples

example 1

[0025] The preparation method of three-dimensional braided carbon fiber reinforced polyether ether ketone composite material is as follows: first, carbon fiber and polyetheretherketone fiber are braided three-dimensionally and four-way, and then the fiber fabric is heated to 140-180 °C, vacuumed continuously, and kept for 1.5 hours, and then Rise to 380°C at a rate of 20°C / min and keep warm for 30min. Pressurize again at 0.5 MPa, remove the vacuum, continue to maintain the temperature for 30 minutes, and finally lower the temperature slowly, and release the mold when the temperature is lower than the glass transition temperature of polyether ether ketone by 30°C. The selected carbon fiber is PAN-based carbon fiber with a tensile strength of 2800MPa, a tensile modulus of 200GPa, and a density of 1.75g / cm 3 , with a diameter of 6-8 μm, produced by Jilin Carbon Plant.

[0026] The three-dimensional braided carbon fiber-reinforced polyetheretherketone composite material with a fi...

example 2

[0028]The three-dimensional braided carbon fiber reinforced polyether ether ketone composite material with a fiber volume content of 54% (the preparation method is the same as in Example 1) was ultrasonically cleaned with acetone, absolute ethanol, and deionized water at room temperature for 10 minutes each, and then dried. Put it in an atmospheric reactor, adjust the frequency to about 8kHz, output voltage about 8kV, current about 40mA, and discharge time for 120s. Then, at 37.5°C, the composite material was placed in 1.5 times SBF simulated body fluid for biomimetic mineralization. The ion solubility of standard simulated body fluid is [Na + ]: 142.0mM, [K + ]: 5.0mM, [Mg 2+ ]: 2mM, [Ca 2+ ]: 2.5mM, [Cl - ]: 147.8mM, [HCO 3 - ]: 4.2mM, [HPO 4 2- ]: 1.0mM, [SO 4 2- ]: 0.4mM, and with trishydroxyaminomethylmethane (CH 2 Oh) 3 CNH 2 and HCl solution as a slow-release agent to adjust the pH value of the solution to 7.4. Take it out after 28 days of bionic mineraliz...

example 3

[0030] The three-dimensional braided carbon fiber reinforced polyether ether ketone composite material with a fiber volume content of 36% (preparation method is the same as in Example 1) was ultrasonically cleaned with acetone, absolute ethanol, and deionized water at room temperature for 10 minutes each, and then dried. It was placed in the MEVVA source ion implanter, with a Ti rod with a purity of 99% as the working electrode, and the implanted side faced the Ti ion source. The injected beam current density is 0.4~0.5mA·cm -2 , the arc voltage is 70V, the trigger voltage is 80V, and the air pressure in the target chamber is about 8×10 -4 Pa, the injection dose is 5.0×10 15 . Then, at 37.5°C, the composite material was placed in 1.5 times SBF simulated body fluid for biomimetic mineralization for 7 days. The ion solubility of standard simulated body fluid is [Na + ]: 142.0mM, [K + ]: 5.0mM, [Mg 2+ ]: 2mM, [Ca 2+ ]: 2.5mM, [Cl - ]: 147.8mM, [HCO 3 - ]: 4.2mM, [HPO 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com