Clad net cloth gluing and surface processing technology

A technology of surface treatment and surface treatment agent, which is applied in the field of sandwich cloth lamination and surface treatment technology, can solve the problem that the physical performance indicators of peel strength and tear strength are not as good as those of scratching, difficult to control production process conditions, and poor air tightness of products Good and other problems, to achieve the effect of improving surface self-cleaning and anti-fouling, low product cost, and scientific and reasonable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

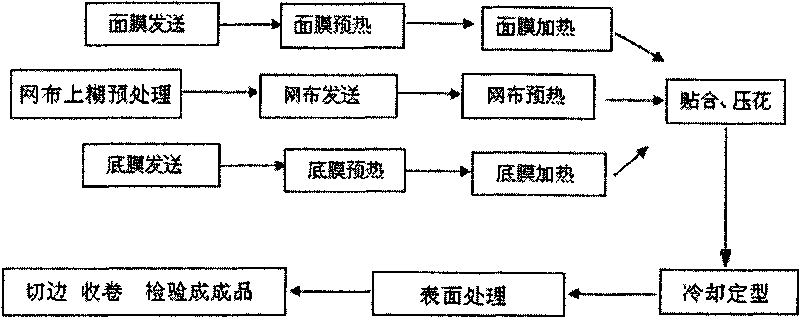

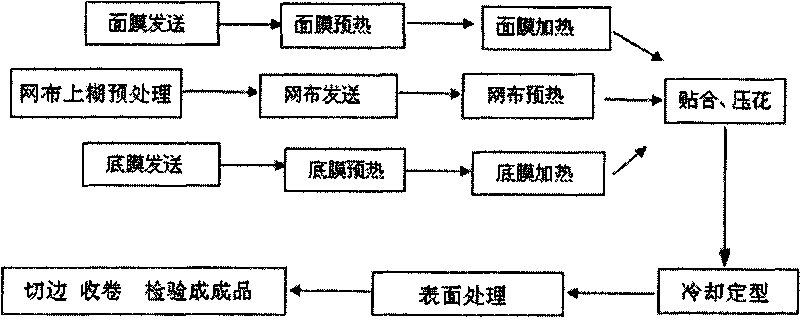

Image

Examples

Embodiment 1

[0022] The specific steps of the production process are:

[0023] (1) Paste pretreatment on the mesh cloth: use a coating machine to carry out PU paste or PVC paste dip coating treatment on the polyester mesh cloth, the raw material formula of the PVC paste is: EPVC 100PHR, and the K value of the EPVC is 63. DINP: 80PHR, liquid low-toxic barium zinc stabilizer 2PHR, solid low-toxic barium zinc stabilizer: 1PHR, P adhesion promoter: 4PHR; the preparation method of PVC paste is: mix EPVC, liquid plasticizer and other additives Soak in the container for 3 days to make it fully absorbed, stir with a high-speed mixer, use the friction and shear force between the material and the barrel wall and the material to fully mix and absorb, and 150 meshes before use Filtration through a filter screen; the PU paste is: according to the mass ratio: PU: methyl ethyl ketone: white glue: bridging agent ratio = 100: 4: 10: 2; mixed and stirred by a mixer; the coating amount is 50 g / m 2 ;

[0...

Embodiment 2

[0036] The specific steps of the production process are:

[0037] (1) Paste pretreatment on the mesh cloth: use a coating machine to carry out PU paste or PVC paste dip coating treatment on the polyester mesh cloth, the raw material formula of the PVC paste is: EPVC 100 PHR, the K value of the EPVC For 63, DINP: 110PHR, liquid low-toxic barium zinc stabilizer 4PHR, solid low-toxic barium zinc stabilizer: 2PHR, P adhesion promoter: 6PHR; the preparation method of PVC paste is: mix EPVC, liquid plasticizer and other Soak the additive container for 5 days to make it fully absorbed, stir it with a high-speed mixer, and use the friction and shear force generated between the material and the barrel wall and the material to fully mix and absorb it. Before use, 150 The purpose filter is filtered; the PU paste is: according to the mass ratio: PU: methyl ethyl ketone: white glue: bridging agent ratio = 100: 4: 10: 2; mixed and stirred by a mixer and prepared; the coating amount is 350...

Embodiment 3

[0050] The specific steps of the production process are:

[0051] (1) Paste pretreatment on the mesh cloth: use a coating machine to carry out PU paste or PVC paste dip coating treatment on the polyester mesh cloth, the raw material formula of the PVC paste is: EPVC 100 PHR, the K value of the EPVC 63, DINP: 100PHR, liquid low-toxic barium zinc stabilizer 3PHR, solid low-toxic barium zinc stabilizer: 1.50PHR, P adhesion promoter: 5PHR; the preparation method of PVC paste is: mix EPVC, liquid plasticizer and Soak the other additives in the container for 4 days to make them fully absorbed, stir them with a high-speed mixer, and use the friction and shear force between the material and the barrel wall and materials to fully mix and absorb them. 150-mesh filter screen; the PU paste is: according to the mass ratio: PU: methyl ethyl ketone: white glue: bridging agent ratio = 100: 4: 10: 2; mixed and stirred by a mixer to prepare; coating amount 250 g / m 2 ;

[0052] (2) Mesh se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com