Environmental hygiene processing system of monomer dispersing type urban sewage source

A technology of urban sewage and treatment system, applied in the field of urban sewage sanitation treatment, which can solve the current and future problems of environmental hazards, costly use, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

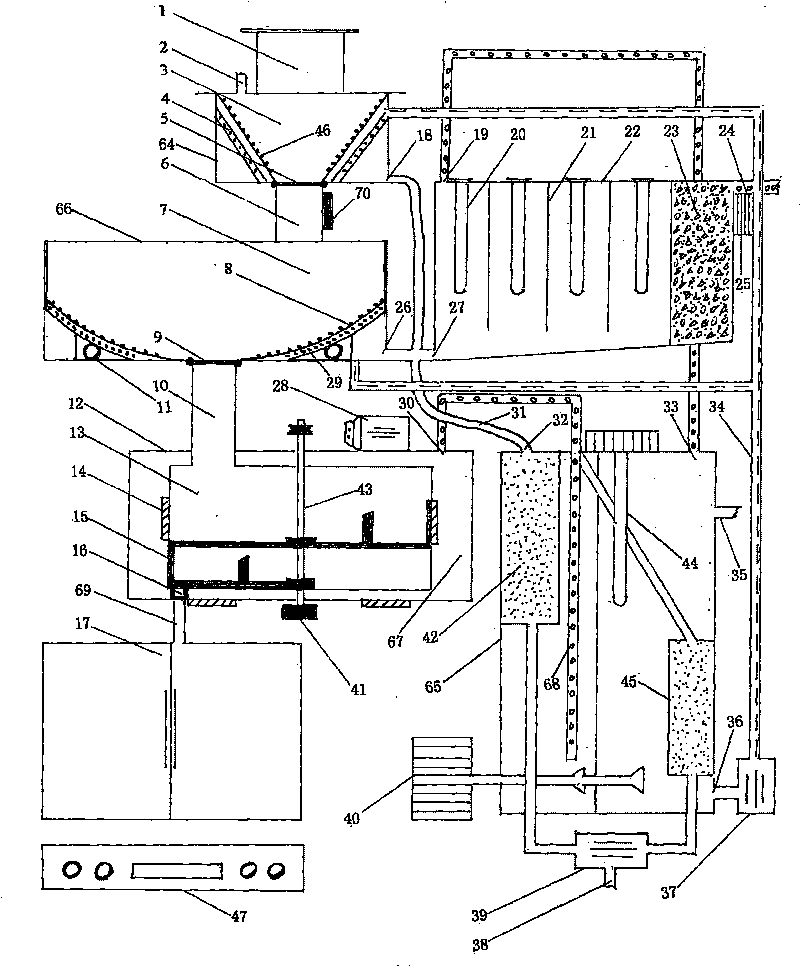

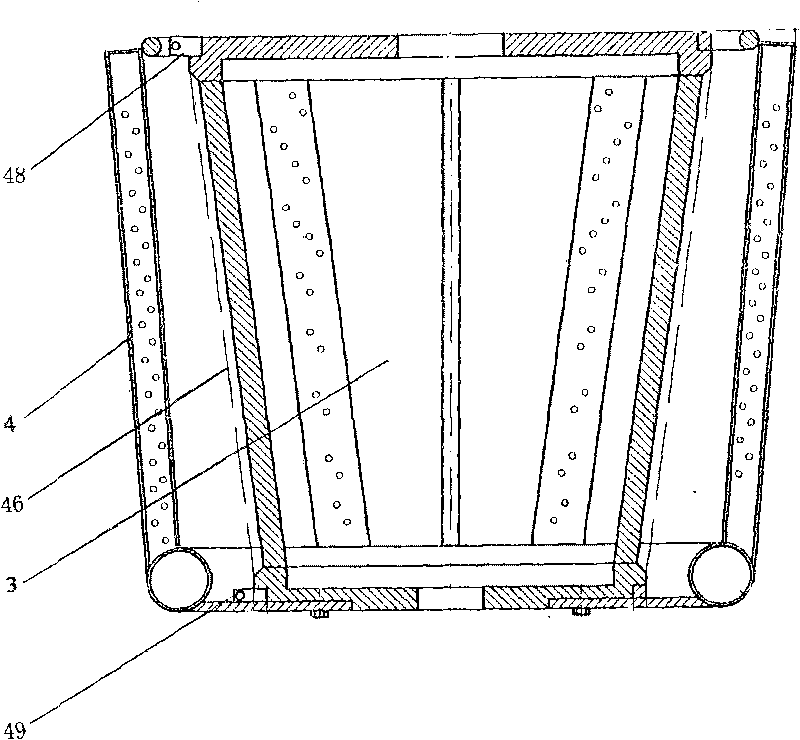

[0041] like figure 1 , figure 2 , Figure 4 As shown, the upper end of the fecal sewage inlet 1 is connected to the building sewer pipe, the lower end of the fecal sewage inlet 1 is connected to the fecal sewage collection and separation device 3, and the separation device sieve 46 is installed in the fecal sewage collection and separation device 3, and the screen surface is covered with sieve holes 53. Separator sieve 46 is fixed by sieve upper frame 48 and sieve lower frame 49, and separator sieve 46 forms interlayer with device shell 64, and the bottom surface of device shell 64 is inclined plane shape, and the low place of inclined plane is provided with separation device sewage outlet 18, and sewage pipe The lead is connected, the sewage pipe is connected to the sewage inlet 32 of the cleaning box, and the separated sewage enters the multi-stage sewage decomposition cleaning box 65, and the bottom of the fecal sewage collection and separation device 3 is provided with...

Embodiment 2

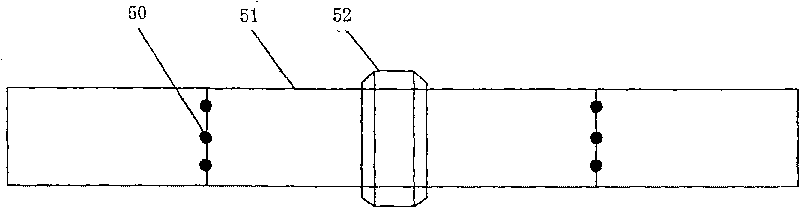

[0043] On the basis of Example 1, as figure 1 , Image 6 , Figure 7 As shown, the secondary separation metering temporary register 7 is connected to the first fecal sludge outlet 6, the secondary separation metering temporary register 7 is installed with a temporary register screen 8, a second backwasher 29, and a No. 2 valve is installed at the bottom 9. It communicates with the second fecal sludge outlet 10, and a meter 11 is installed at the bottom of the secondary separation metering temporary storage 7. The switching methods of the No. 1 valve 5, the No. 2 valve 9 and the No. 3 valve 16 are the same, and the gear 57 and the tooth Composed of strips 58, fixed with bolts through the fixing holes 59, the temporary storage sewage outlet 26 is set at the lower slope of the bottom of the temporary storage shell 66, and communicates with the sewage pipe 31, and the fecal sludge stored reaches the standard set by the meter 11. No. valve 9 is opened, and fecal sludge falls in t...

Embodiment 3

[0045] On the basis of test example 1 and example 2, if figure 1 As shown, the low-temperature pyrolysis sterilization bin 67 is connected to the second fecal sludge outlet 10 . A pyrolysis pot 13 is installed in the pyrolysis chamber shell 12, and heaters 14 are installed on the outside and bottom of the pyrolysis pot 13. There are three kinds of heat sources for heating: microwave energy, electromagnetic energy and infrared rays, and a stirring and pulverizing knife 15 is installed inside the pyrolysis pot 13. , is fixed by the central shaft 43 of the stirring and crushing knife, driven by the motor 28, the lower end of the central shaft 43 of the stirring and pulverizing knife is installed with a bearing 41, and the upper part of the pyrolysis chamber shell 12 is provided with a pyrolysis chamber sewage gas outlet 30 communicated with the sewage gas pipe 68, and the low-temperature heating The No. 3 valve 16 is set at the bottom of the sterilization chamber 67, and the feca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com