Apparatus for processing fecal sewage into reclaimed water at source

A technology for fecal sewage and reclaimed water, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, biological organic part treatment, etc. It can solve the problems of high cost, unavailability and influence, and achieve low manufacturing cost. , easy to operate, the effect of improving soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

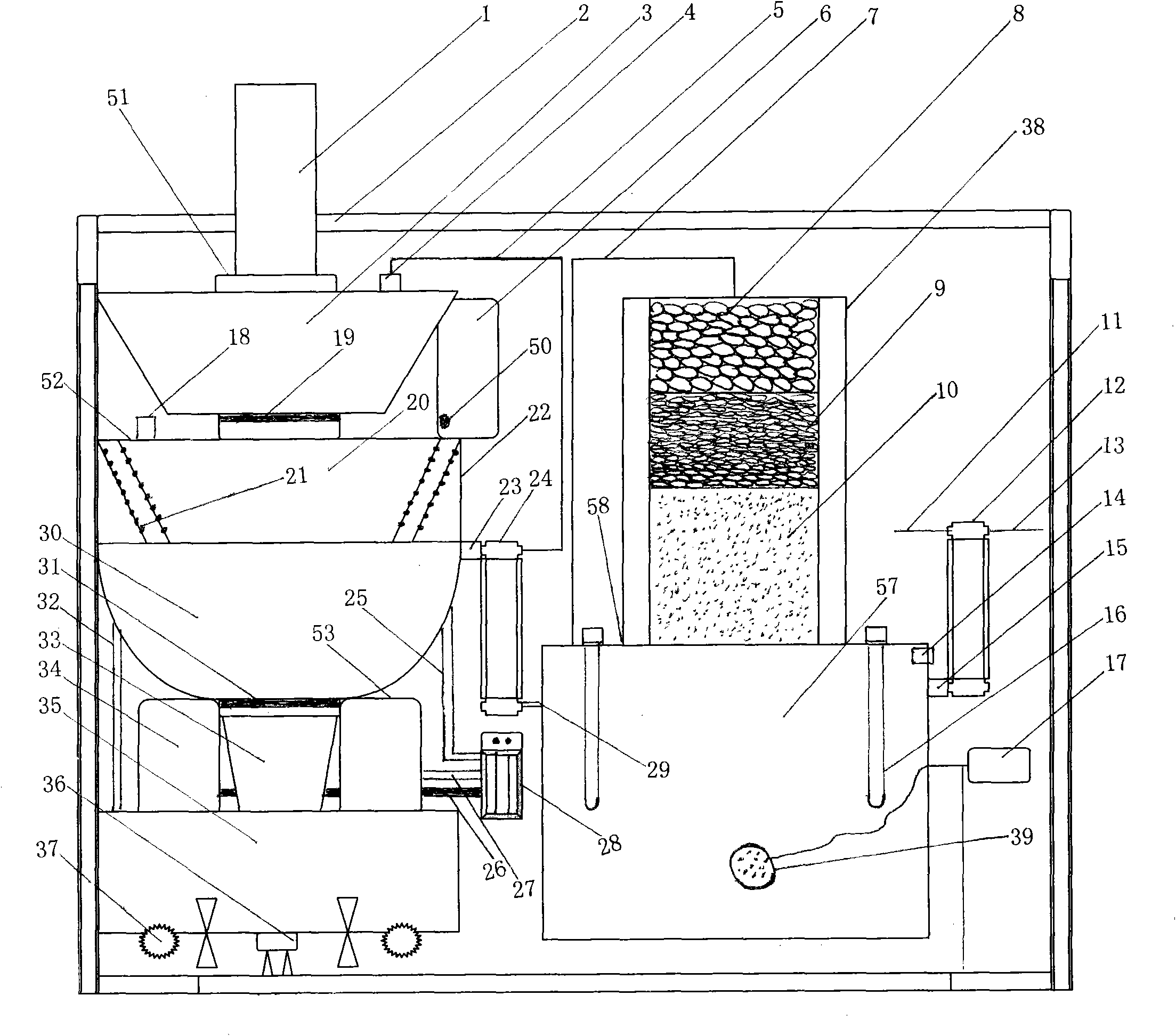

[0036] Such as figure 1 As shown, the upper end of the fecal sewage inlet 1 is connected to the sewer pipe of the building toilet, and the lower end is installed with a descaling device 51 to communicate with the collection and flocculation device 3. The upper part of the collection and flocculation device 3 is provided with a filter residue inlet 4 and communicates with the slag discharge pipe 5. The lower part is provided with No. 1 valve 19 communicating with the solid-liquid separation device 22, and the flocculant tank 6 is installed on the outside to communicate with the collecting and flocculating device 3. The flocculant tank 6 is connected to the pressure pump 28 through the flocculant tank pressure pipe 25. The first material-free alarm 50 is installed.

Embodiment 2

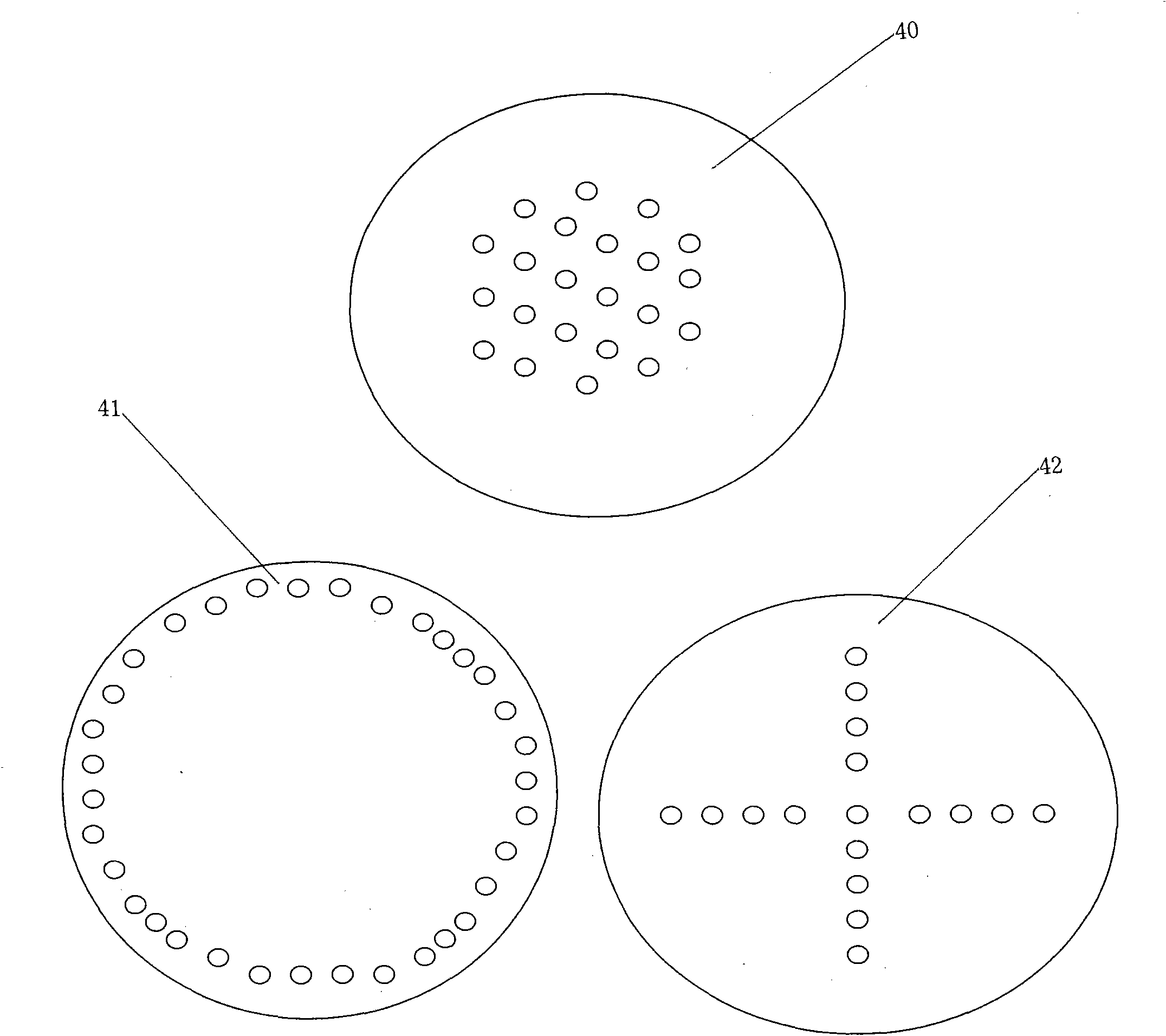

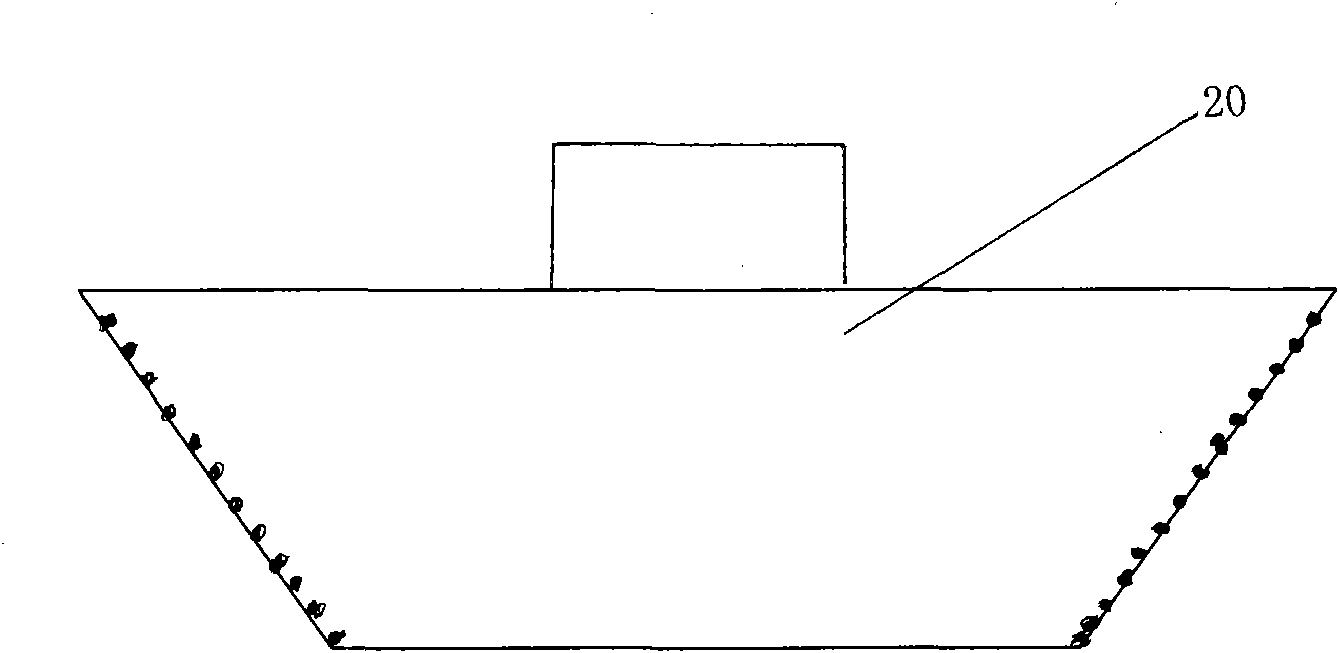

[0038] On the basis of Example 1, as figure 1 , image 3 , Figure 4 , Figure 5 As shown, the solid-liquid separation device 22 is installed below the collection and flocculation device 3, the solid-liquid separation device 22 is composed of a separator 52 and a sedimentation tank 30, and the separator 52 is composed of a separator inner cavity 20 and a separator outer cavity 49 . A separator mesh 43 is provided on the wall of the separator inner cavity 20 , and a backwasher 21 is installed in the separator 52 . Water regularly cleans the separator mesh 43 . The separator outer cavity 49 is provided with a sewage outlet 23 communicating with the sewage filtering device 24 . No. 2 valve 31 is installed at the bottom of precipitation kettle 30 .

Embodiment 3

[0040] On the basis of embodiment one and example two, as figure 1 , Figure 6 As shown, a sludge sterilizing device 33 is installed below the No. 2 valve 31, a dry powder sprayer 34 is installed on the outside of the sludge sterilizing device 33, and a spare sprayer 53 is installed in the opposite direction on the outside. The spare sprayer 53 has the same structure as the dry powder sprayer 34. The nozzle 45 is inserted into the sludge sterilizing device 33 . The dry powder sprayer 34 is provided with an upper cavity 54, a middle cavity 55, and a lower cavity 56, and materials are added through the feeding port 47, and a second no-material alarm 46 is installed outside. The pressure storage tank 48 is connected to the sprayer pressurizing pipe 26 to provide the spray pressure of the dry powder sprayer 34, and the pressurized backup pipe 27 provides the spray pressure of the spare sprayer 53, and the sprayer pressurized pipe 26 and the pressurized spare pipe 27 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com