Device for detecting thickness of photoresist on curved surface and method for detecting thickness of photoresist on curved surface point by point

A detection device and curved surface technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that the accuracy and accuracy cannot be guaranteed, and there is no thickness distribution of photoresist.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

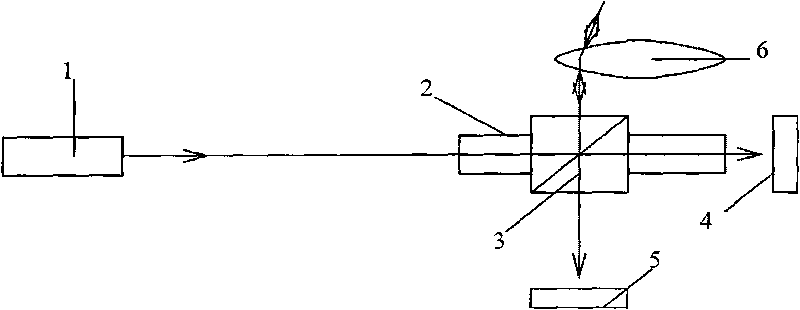

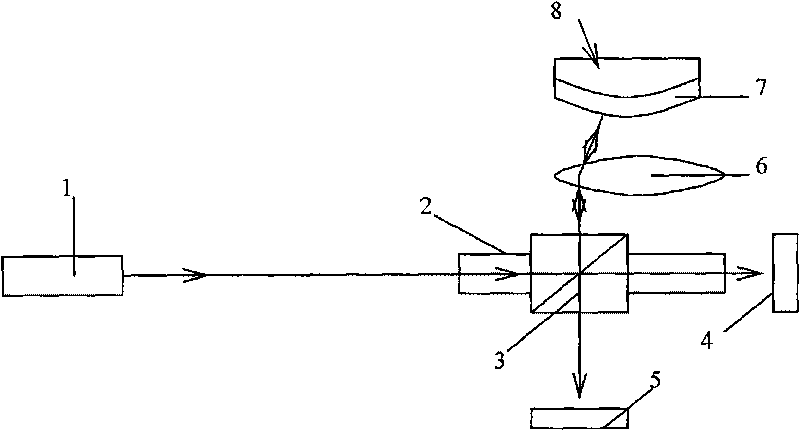

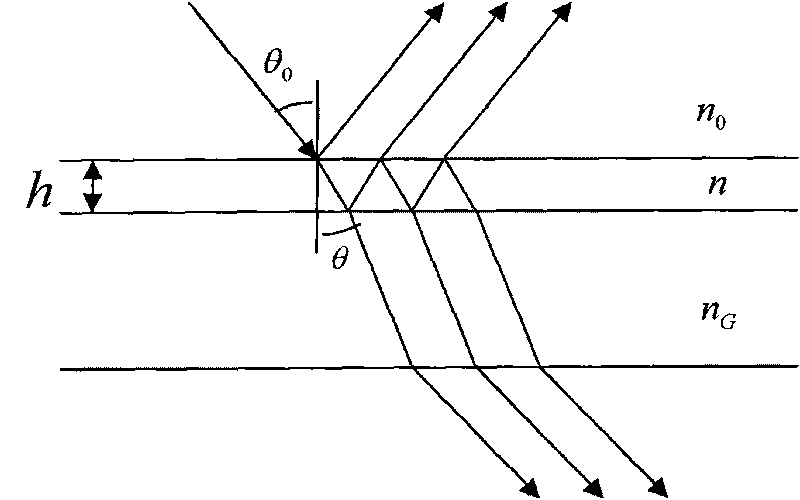

[0025] Such as figure 1 As shown, the point-by-point detection device for curved surface glue thickness of the present invention mainly includes: a laser transmitter 1 , a guide rail 2 , a beam splitting prism 3 , a first optical power meter 4 , a second optical power meter 5 and a lens 6 . Wherein, the dichroic prism 3 is arranged on the guide rail 2 . The dichroic prism 3 can move along the guide rail 2 to change the direction of the outgoing light passing through the dichroic prism 3 . The spherical center of the curved surface of the sample to be tested is located at the focal point of the lens 6, and the sample to be tested is held by a holder. The first optical power meter 4 and the second optical power meter 5 synchronously record the intensity of the transmitted light from the dichroic prism 3 and the light intensity of the reflected light reflected from the adhesive layer of the substrate.

[0026] When using the detection device of the present invention to detect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com