Design method of remanent magnetism mechanism of recombiner and remanent magnetism mechanism

A design method and technology of recloser, applied in the field of recloser and operating mechanism, can solve the problems of large instantaneous power mechanical characteristic control, complicated controller, etc., and achieve the effect of fast response speed, small closing current and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

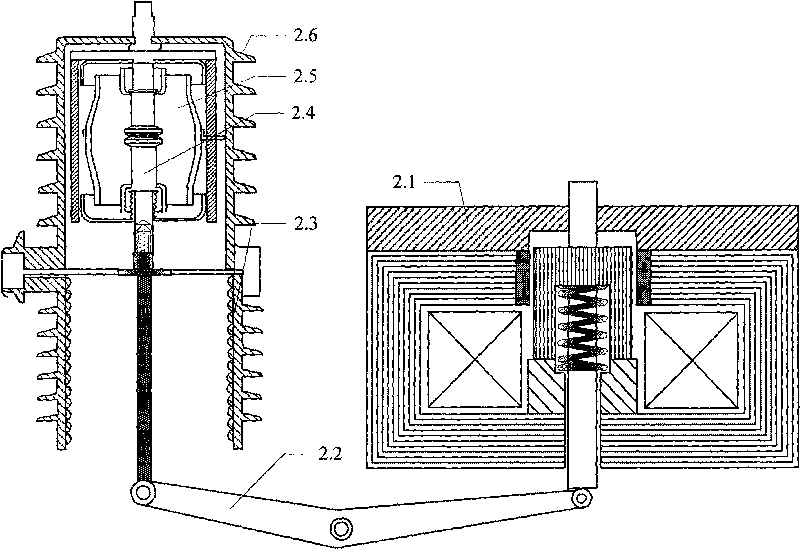

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

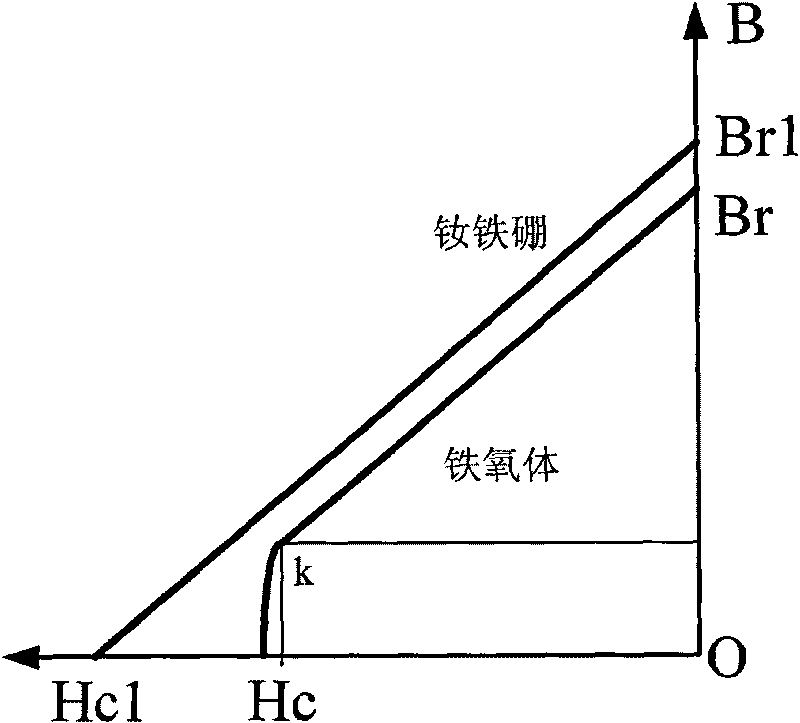

[0039] A method for designing a residual magnetic mechanism of a recloser is characterized in that silicon steel materials are used as the material of the magnetic circuit of the residual magnetic mechanism of the recloser, and the specific steps include:

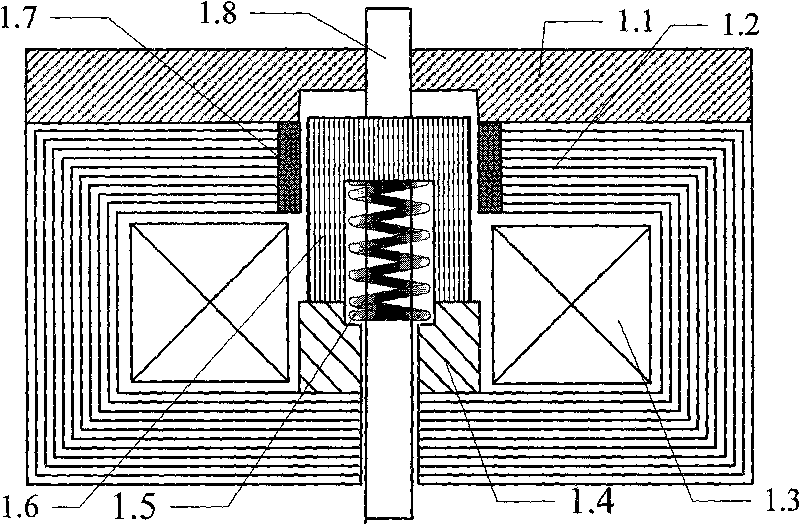

[0040] 1) The yoke is made of silicon steel; a cavity is set in the yoke, and a closing coil is set in the cavity; a through hole is set in the middle of the bottom of the cavity;

[0041] 2) A moving iron core is set in the middle of the closing coil, and the moving iron core is used to drive the pull rod; an elastic body is set in the middle of the closing coil, and the elastic force of the elastic body on the moving iron core is opposite to the magnetic force of the moving iron core after the closing coil is energized. Control the movement of the moving iron core in the axial direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com