Soft magnetic composite material and preparation method and application thereof

A soft magnetic composite material and magnetic powder technology, which is applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of high noise and high magnetic loss, and achieve low eddy current loss, low magnetic loss, Effect of reducing eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

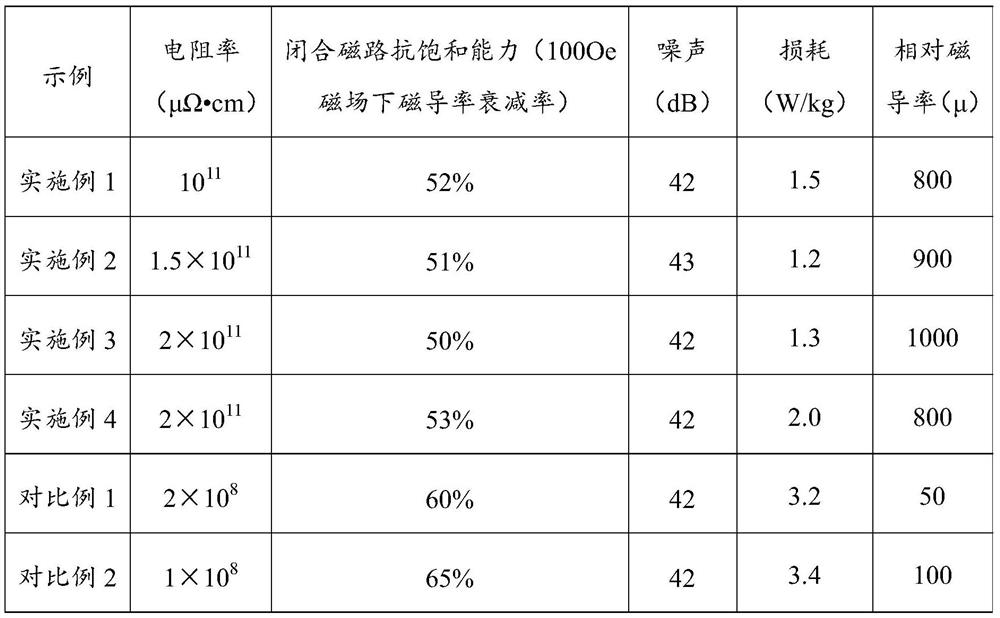

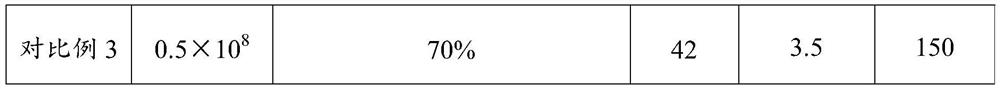

Examples

Embodiment 1

[0041] This embodiment provides a soft magnetic composite material and a preparation method thereof, comprising the following steps,

[0042] (1) Use the aerosol method to carry out particle size classification on the alloy matrix powder, and then fully mix it evenly. The particle size of the alloy matrix powder after particle size classification is 100 mesh; wherein, in terms of atomic percentage, the alloy matrix powder includes 81.2wt% Fe, 4wt% %Si, 3wt% Al, 0.8wt% B, 6wt% Ni, 2wt% Nb and 3wt% N; wherein, N is added in the form of SiN powder.

[0043] (2) Add the nano-oxide suspension and instant sodium silicate powder to the alloy matrix powder obtained in step (1), stir evenly to form a slurry, heat and keep stirring at 50°C until the slurry is dry, fully Grinding and drying the slurry and sieving through a 50-mesh particle size to obtain magnetic powder coated with an insulating layer; wherein the nano-oxide suspension includes 10% PbPdO 2 and SiO with a mass fraction o...

Embodiment 2

[0046] This embodiment provides a soft magnetic composite material and a preparation method thereof, comprising the following steps,

[0047] (1) Use the aerosol method to carry out particle size classification on the alloy matrix powder, and then fully mix it evenly. The particle size of the alloy matrix powder after particle size classification is 400 mesh; wherein, in terms of atomic percentage, the alloy matrix powder includes 80.3wt% Fe, 6wt% %Si, 5wt% Al, 0.2wt% B, 8wt% Ni, 0.3wt% Nb and 0.2wt% N; N was added in the form of SiN powder.

[0048] (2) Add the nano-oxide suspension and the instant sodium silicate powder to the alloy matrix powder obtained in step (1), stir evenly to form a slurry, heat and keep stirring at 80°C until the slurry is dry, fully Grinding and drying the slurry and passing through 100 mesh particle size screening to obtain magnetic powder coated with an insulating layer; wherein the nano-oxide suspension contains 15% PbPdO 2 and SiO with a mass f...

Embodiment 3

[0051] This embodiment provides a soft magnetic composite material and a preparation method thereof, comprising the following steps,

[0052] (1) Use the aerosol method to carry out particle size classification on the alloy matrix powder, and then fully mix it evenly. The particle size of the alloy matrix powder after particle size classification is 200 mesh; wherein, in terms of atomic percentage, the alloy matrix powder includes 80wt% Fe, 3wt% Si, 9wt% Al, 0.5wt% B, 2wt% Ni, 1.5wt% Nb and 4wt% N; N was added in the form of SiN powder.

[0053] (2) Add the nano-oxide suspension and instant sodium silicate powder to the alloy matrix powder obtained in step (1), stir evenly to form a slurry, heat and keep stirring at 60°C until the slurry is dry, fully Grinding the dried slurry and sieving through 80 mesh particle size to obtain magnetic powder coated with an insulating layer; wherein, the nano-oxide suspension contains 13% PbPdO 2 and SiO with a mass fraction of 7% 2 , PbPdO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com