Bus and bus assembly for electric transmission

A technology for power transmission and busbars, applied in the field of busbars and their busbar assemblies, can solve problems such as unprovided connections, and achieve the effects of increasing the contact area between metals, good electrical conductivity, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] (Example 1, busbar for power transmission)

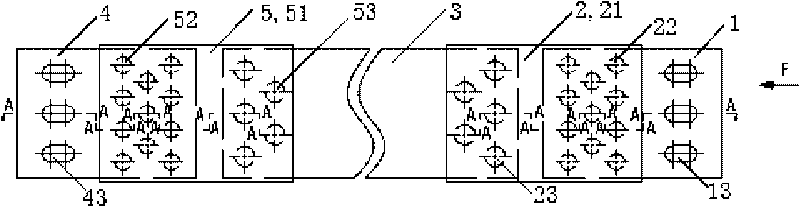

[0085] See figure 1 , The bus bar for power transmission in this embodiment includes a first copper plate 1 , a first cast aluminum plate 2 , an aluminum bar 3 , a second copper plate 4 and a second cast aluminum plate 5 .

[0086] See figure 2 The aluminum row 3 includes a group of round holes 31 perpendicular to the plate surface of the aluminum row 3 on the left end of the aluminum row 3 on the aluminum row 3 and the right end of the aluminum row 3 on the aluminum row 3 Another group of circular holes 32 perpendicular to the plate surface of the aluminum row 3.

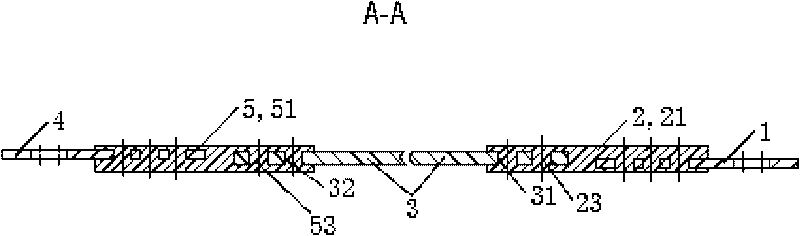

[0087] See image 3 and Figure 4 , the first copper plate 1 is a stamped pure copper rectangular plate with a thickness of 3 to 5 millimeters (4 millimeters in this embodiment), which includes the first pure copper plate body 11, the first pure copper plate body 11 located on the first pure copper plate body 11 Eleven connecting holes 12 perpendicular to th...

Embodiment 2

[0103] (Example 2, busbar for power transmission)

[0104] The rest of the busbar for power transmission in this embodiment is the same as that in Embodiment 1, except that:

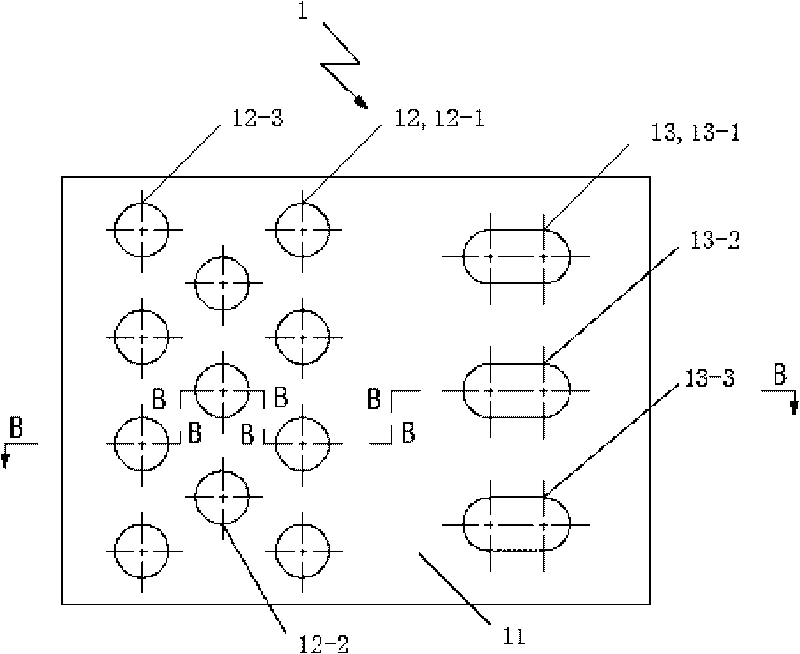

[0105] See Figure 11 , a group of bolt holes 13 on the first copper plate 1 has 6 in total, divided into two rows on the left and right, and a row on the left side has 3 bolt holes 13, each of which is a waist hole, and is distributed at equal intervals according to the up and down direction, from top to bottom These are the first bolt hole 13-1, the second bolt hole 13-2 and the third bolt hole 13-3 in sequence. There are three bolt holes 13 in a row on the right side, each of which is a round hole, and is equally spaced according to the up and down direction, and from top to bottom are the fourth bolt hole 13-4, the fifth bolt hole 13-5 and the sixth bolt Holes 13-6.

[0106] See Figure 12 , a group of bolt holes 43 of the second copper plate 4 has 6 in total, divided into left and right rows, an...

Embodiment 3

[0108] (Example 3, busbar assembly for power transmission)

[0109] Select the 4 busbars obtained in Example 1, among which 3 with larger dimensions are used as A, B, and C three-phase lines, and another one with the same structure and smaller size is used as the neutral line. See Figure 15 , The busbar assembly for power transmission in this embodiment further includes an insulating frame 7 , a square pipe 8 and an insulating mounting block 6 .

[0110] See Figure 14 , The insulating frame 7 includes an upper insulating frame 71 and a lower insulating frame 72 . The overall shape of the upper insulating frame 71 and the lower insulating frame 72 is cuboid, made of insulating ceramics. The upper part of the lower insulating frame 72 is provided with 4 front and rear equally spaced grooves from left to right. The 3 grooves on the left have the same shape, and the groove on the far right is slightly smaller than the groove on the left. The bottom of the upper insulating f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com