Method for processing pyracantha fortuneana juice

A processing method and juice technology, which are applied in the processing field of concentrated sterilization of Pyracantha juice, can solve the problems of unfavorable juice quality and reduced juice efficacy, and achieve the effects of better appearance quality, high speed and high similarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

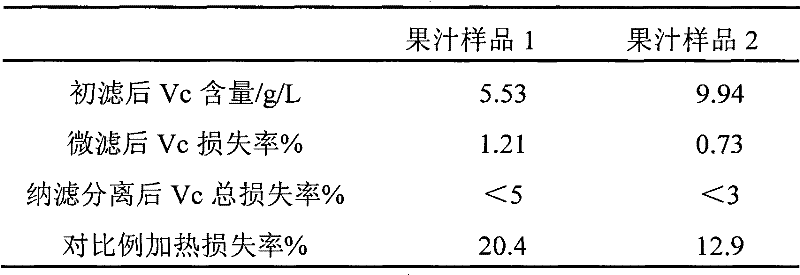

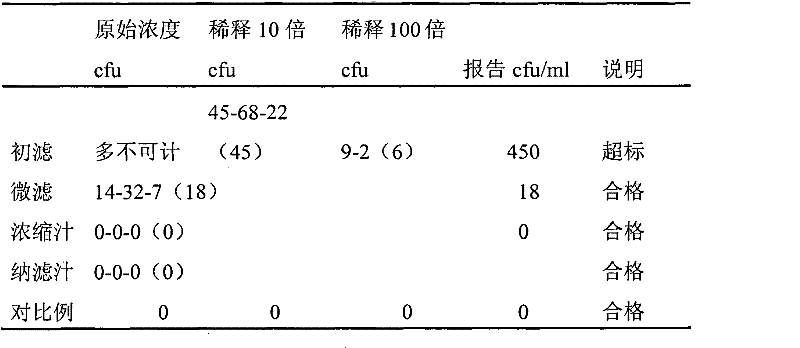

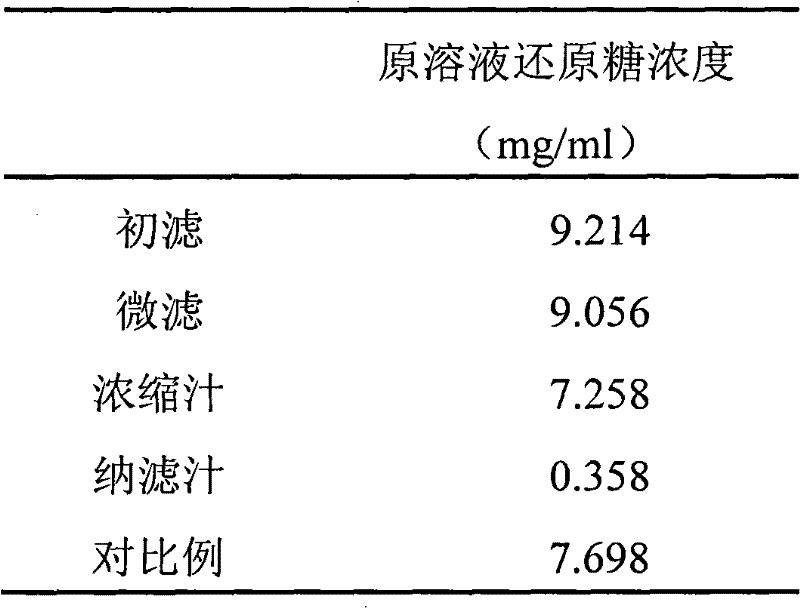

Examples

Embodiment 1

[0025] Embodiment 1, the sequence includes:

[0026] 1. Primary filtration step: the freshly squeezed and diluted Pyracantha japonicus juice is first pretreated, and the juice is filtered with a filter cloth with a pore size of 0.01mm; then, the pretreated Pyracantha japonicus juice is centrifuged at room temperature at a speed of 2000rpm After 40 minutes, after removing the solidified matter, use a Buchner funnel to filter under reduced pressure to remove suspended matter and most of the solid particles to obtain the primary filtered juice;

[0027] 2. Micron-level filtration step: Use the first membrane separation device to filter the first-level filtered juice in a non-gravity direction to obtain the second-level filtered juice, and put it into a clean and sealed oxygen-insulated container; pre-filter the filter membrane of the first membrane separation device The reverse filtration direction is washed with 0.1mol / L hydrochloric acid and pure water in turn. The filter membr...

Embodiment 2

[0048] Embodiment 2, the sequence includes:

[0049] 1. Primary filtration step: the freshly squeezed and diluted Pyracantha japonicus juice is first pretreated, and the juice is filtered with a filter cloth with a pore size of 0.1mm; then, the pretreated Pyracantha japonicus juice is centrifuged at room temperature at a speed of 5000rpm Treat for 15 minutes, remove the solidified matter, and use a Buchner funnel to filter under reduced pressure to remove suspended matter and most of the solid particles to obtain the primary filtered juice;

[0050] 2. Micron-level filtration step: Use the first membrane separation device to filter the first-level filtered juice in a non-gravity direction to obtain the second-level filtered juice, and put it into a clean and sealed oxygen-insulated container; pre-filter the filter membrane of the first membrane separation device The reverse filtration direction is washed with 0.1mol / L hydrochloric acid and pure water in turn. The filter membra...

Embodiment 3

[0071] Embodiment 3, the sequence includes:

[0072] 1. Primary filtration step: the freshly squeezed and diluted Pyracantha japonicus juice is first pretreated, and the juice is filtered with a filter cloth with a pore size of 0.05 mm; then, the pretreated Pyracantha japonicus juice is centrifuged at room temperature at a speed of 4000 rpm After 20 minutes, after removing the solidified matter, use a Buchner funnel to filter under reduced pressure to remove suspended matter and most of the solid particles to obtain the primary filtered juice;

[0073] 2. Micron-level filtration step: Use the first membrane separation device to filter the first-level filtered juice in a non-gravity direction to obtain the second-level filtered juice, and put it into a clean and sealed oxygen-insulated container; pre-filter the filter membrane of the first membrane separation device The reverse filtration direction is washed with 0.1mol / L hydrochloric acid and pure water in sequence. The filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com