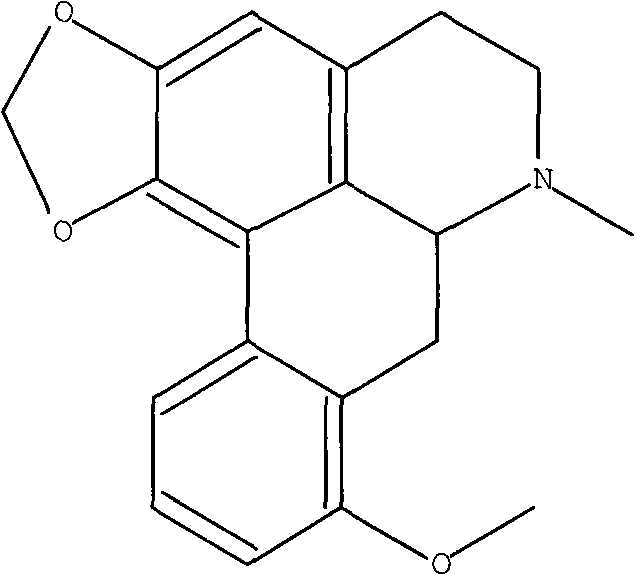

Method for preparing stephanine

A stephanine and stephenine technology, which is applied in the field of stephenine preparation, can solve the problems of unfavorable large-scale production operations, serious pollution, and low stephenine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take 10Kg of fresh Stephania vine roots and stems, add 10 times its weight in water and soak for 24 hours, separate the medicinal solution, filter, concentrate, adjust the pH value to 11 with concentrated ammonia water, add an equal volume of chloroform for extraction, take the chloroform layer, and recover the solvent And dry to get the total alkaloids, add chloroform to dissolve, inject high-efficiency countercurrent extractor, use chloroform-0.07mol / L sodium phosphate-0.04mol / L citric acid buffer solvent system, the upper phase is the stationary phase, and the lower phase is the mobile phase , collect steppaline segments, concentrate, collect crystals, wash and dry to obtain 5.4 g steppineine, which is detected by HPLC with a purity of 98.6%.

Embodiment 2

[0018] Take 10Kg of fresh Stephania vine roots and stems, add 12 times its weight in water and soak for 72 hours, separate the liquid medicine, filter, concentrate, adjust the pH value to 14 with concentrated ammonia water, add an equal volume of chloroform for extraction, take the chloroform layer, and recover the solvent And dry to get the total alkaloids, add chloroform to dissolve, inject high-efficiency countercurrent extractor, use chloroform-0.07mol / L sodium phosphate-0.04mol / L citric acid buffer solvent system, the upper phase is the stationary phase, and the lower phase is the mobile phase , collect steppaline segments, concentrate, collect crystals, wash and dry to obtain 8.4 g steppineine, which is detected by HPLC with a purity of 98.3%.

Embodiment 3

[0020] Take 10Kg of fresh Stephania vine roots and stems, add 15 times its weight in water and soak for 48 hours, separate the liquid medicine, filter, concentrate, adjust the pH value to 13 with concentrated ammonia water, add an equal volume of chloroform for extraction, take the chloroform layer, and recover the solvent And dry to get the total alkaloids, add chloroform to dissolve, inject high-efficiency countercurrent extractor, use chloroform-0.07mol / L sodium phosphate-0.04mol / L citric acid buffer solvent system, the upper phase is the stationary phase, and the lower phase is the mobile phase , collect the stephine segment, concentrate, collect the crystals, wash and dry to obtain 7.6 g stephine, which is detected by HPLC with a purity of 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com