Loading device and loading mode for use in measurement of hydrogen diffusion in stress field

A loading device and stress field technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as test structure interference, decision-making affecting hydrogen diffusion, test structure data dispersion, etc., to achieve the effect of reducing deviation and effective evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

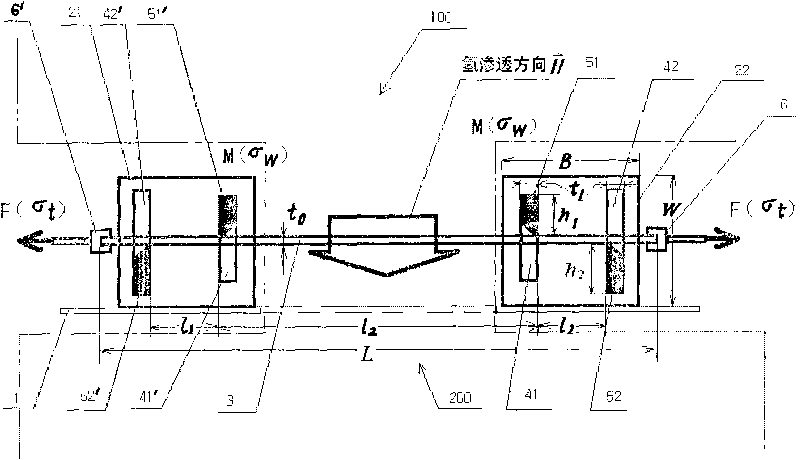

[0048] A loading device for hydrogen diffusion measurement in stress field, such as figure 1 Shown, including:

[0049] Positioning frame 1, a rigid support arranged between the hydrogen permeation double electrolytic cell 100 and 200, on which a chute is arranged along the long axis of the sample to be tested;

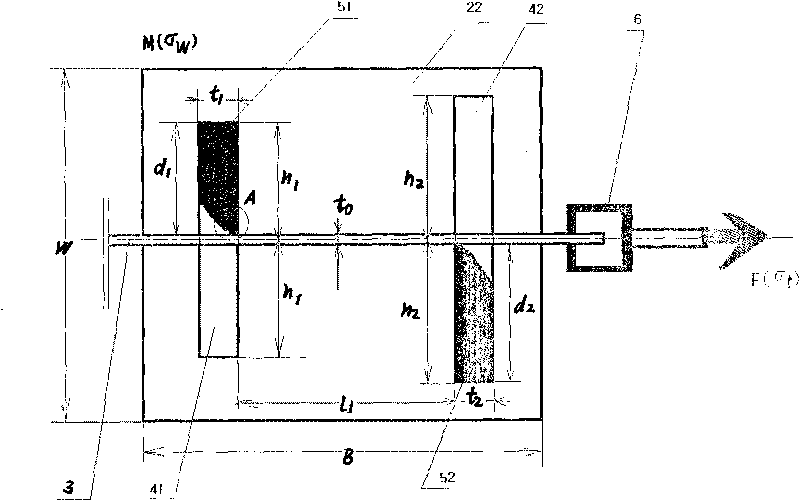

[0050] The two sets of loading frames 21 and 22 are supported by the positioning frame 1, arranged in parallel along the long axis of the sample 3 to be tested, and can slide along the chute in the positioning frame 1. Each set of loading frames includes two main frames, which are separate On both sides of the test sample 3 along the short axis direction, sandwich the test sample 3 and perpendicular to the upper and lower surfaces of the test sample 3, such as figure 2 Shown

[0051] The loading windows 41, 42, 41', 42' are opened on each group of loading frames 21, 22. The upper and lower surfaces of the sample 3 to be tested are the vertical planes, and they are divided i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com