Zinc oxide/cuprous oxide nano heterojunction photocatalytic material and method for preparing same

A technology of photocatalytic materials and zinc oxide nanorods, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, chemical instruments and methods, etc., to achieve the effect of improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

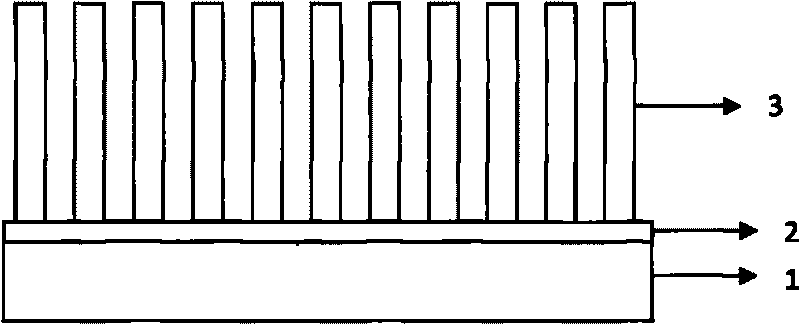

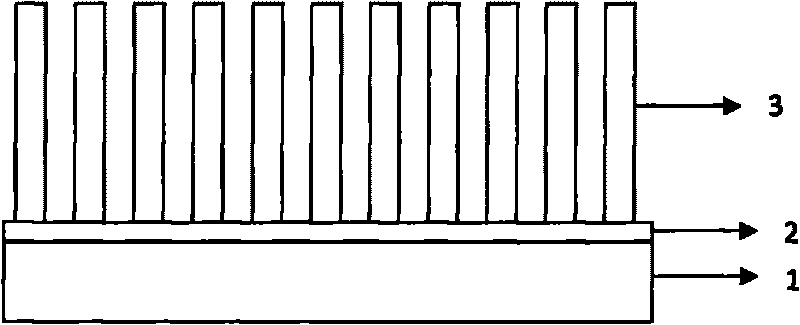

[0034] (1) Zinc oxide / cuprous oxide nano-heterojunction photocatalytic material of the present invention, such as figure 1 As shown, its structural composition is as follows: it is composed of silicon substrate 1 , cuprous oxide film 2 deposited on silicon substrate 1 and zinc oxide nanorods 3 grown in liquid phase on cuprous oxide film 2 .

[0035] The silicon substrate 1 is a single crystal silicon wafer of (111) plane.

[0036] The thickness of the cuprous oxide film 2 is 150nm.

[0037] The zinc oxide nanorods 3 have a length of 300nm and a diameter of 40nm.

[0038] (2) The preparation method of zinc oxide / cuprous oxide nano-heterojunction photocatalytic material of the present invention, the concrete steps of this method are as follows:

[0039] Step 1: Preparation of substrate

[0040] Cut the purchased Si wafer into a substrate suitable for the size of the instrument and equipment, boil the cut substrate in a mixed solution of concentrated sulfuric acid and hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com