Magnetic styrene alkali anion exchange microsphere resin and preparation method thereof

A styrene-based, anion technology, applied in anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of difficult and uniform distribution of magnetic particles, achieve simplified synthesis process, high alkali exchange capacity, avoid chloromethyl Effects of the basement process

Inactive Publication Date: 2010-05-19

江苏国创饮用水净化工程中心有限公司

View PDF0 Cites 33 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at problems such as high exchange capacity and strong magnetic resin products cannot be prepared, magnetic particles are difficult to exist stably in the synthesis process, and are difficult to distribute evenly, the magnetic styrene-based strong base anion exchange resin provided by the present invention and its The preparation method aims to prepare the magnetic styrene-based strong base anion exchange microsphere resin with strong magnetism and high exchange capacity, and uses a simple and easy process to uniformly disperse the magnetic particles in the monomer. The monomers containing chloromethyl groups are polymerized as monomers, avoiding the chloromethylation process, protecting the magnetic particles, and finally realizing the synthesis of magnetic strong base ion exchange resins

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

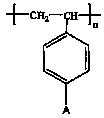

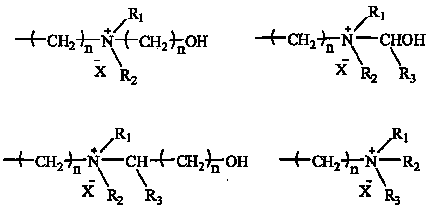

The invention discloses a magnetic styrene alkali anion exchange microsphere resin and a preparation method thereof. The resin comprises a basic framework and magnetic particles positioned inside the basic framework. The basic framework of the resin has the structure as follows: radical A is one or a plurality of the picture below, wherein n is 1, 2, 3 to 20, R1, R2 and R3 are alkyl, and X is C1 or OH. The method comprises the following steps of: adding a dispersant to a water phase; mixing reactants, a stabilizing agent and a pore-foaming agent to form an oil phase; adding an evocating agent to the oil phase for full dissolution; adding the magnetic particles to the oil phase, adding the oil phase to the water phase to obtain resin particles, filtering to remove water content, and washing or extracting the resin particles; and swelling the obtained resin particles, and adding an amine reagent. The invention simplifies traditional synthesis process, and prepared resin has magnetism and has higher alkali exchange capacity and can be used for separating or removing dissolved organic matters and a plurality of anions in various wastewater, drinking water or natural water.

Description

technical field The invention relates to a strong base anion exchange microsphere resin and a preparation method thereof, in particular to a styrene series strong base anion exchange microsphere resin containing magnetic particles inside and a preparation method thereof. Background technique Styrene resins are currently the most productive resins in the world, and are widely used in separation, purification and detection of bioengineering, drug synthesis, and food processing. In recent years, macroporous styrene-based anion exchange resins have played an important role in the treatment and recycling of wastewater. However, the adsorption and desorption performance of the resin is often controlled by kinetic factors. The resin with smaller particles has a higher external specific surface area, and the kinetic performance is also greatly improved, so its adsorption and desorption performance is obviously superior to that of the resin. Resin with larger particles. However, in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J41/14

Inventor 李爱民双陈冬薛玉志周友冬龙超刘福强周庆王津南张满成

Owner 江苏国创饮用水净化工程中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com