Ecological type BOPP/PP color printing food packaging film and preparation method thereof

A food packaging film and color printing technology, which is applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of poor environmental protection and hidden dangers of food safety, and achieve the effects of preventing oxidative deterioration, prolonging the effective shelf life, and enhancing environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

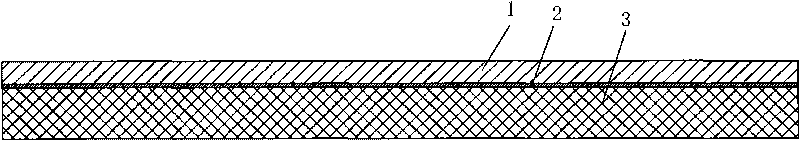

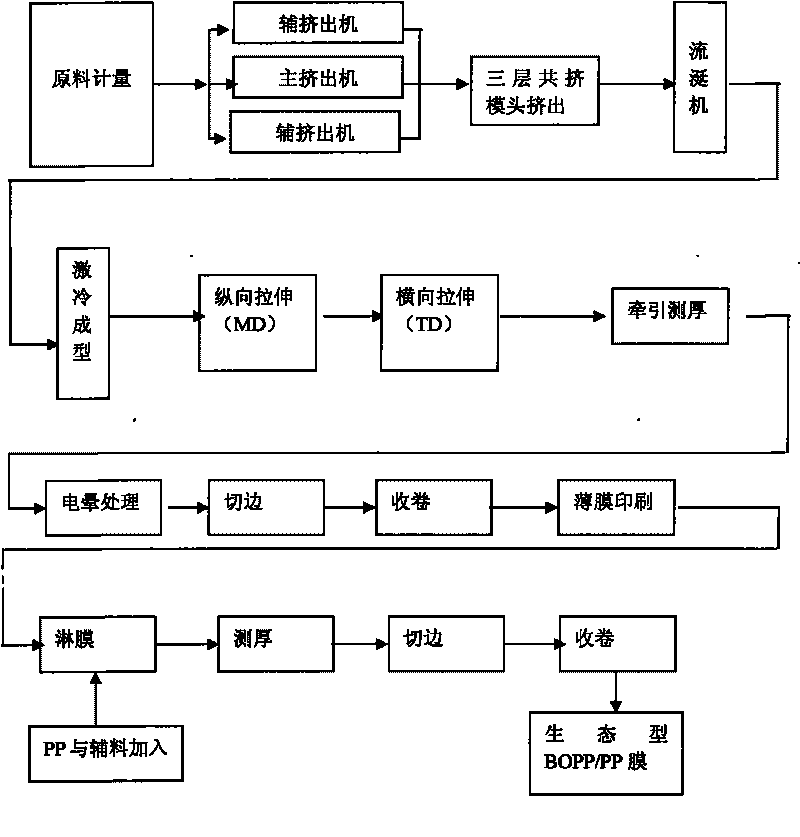

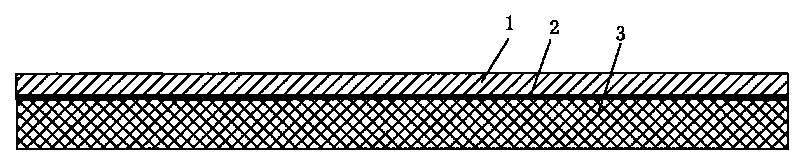

[0026] An ecological BOPP / PP color printing food packaging film, comprising an upper layer 1, a middle layer 2 and a lower layer 3, the middle layer 2 is covered on the lower layer 3, the upper layer 1 is covered on the middle layer 2, The upper layer 1 is a PP coating layer, the middle layer 2 is a color printing film layer, and the lower layer 3 is a BOPP layer.

[0027] In the eco-type BOPP / PP color printing food packaging film, the percentage of each layer in the total mass is: PP coating layer: 15-32%, color printing film layer: 1-3%, BOPP layer: 65-82%

[0028] In the PP coating layer, the raw materials are PP material and barrier material montmorillonite sodium salt, the auxiliary material is deoxidizer, and the deoxidizer is nano-reduced iron powder, and the mass percentage of each component is: PP material: 88-95% %, barrier material montmorillonite sodium salt: 2-7%, nano-reduced iron powder: 3-7%.

[0029] In this example, PP coating layer: 15%, color printing film...

Embodiment 2

[0039] In this example, PP coating layer: 18%, color printing film layer: 2%, BOPP layer: 80%

[0040] In the PP coating layer, the raw materials are PP material and barrier material montmorillonite sodium salt, the auxiliary material is a deoxidizer, and the deoxidizer is nano-reduced iron powder, and the mass percentage of each component is: PP material: 89%, Barrier material montmorillonite sodium salt: 6.5%, nano-reduced iron powder: 4.5%.

[0041] Other schemes of this embodiment are all the same as in Embodiment 1.

Embodiment 3

[0043] In this example, PP coating layer: 24%, color printing film layer: 1.5%, BOPP layer: 74.5%

[0044] In the PP coating layer, the raw materials are PP material and barrier material montmorillonite sodium salt, the auxiliary material is deoxidizer, and the deoxidizer is nano-reduced iron powder, and the mass percentage of each component is: PP material: 90%, Barrier material montmorillonite sodium salt: 6%, nano-reduced iron powder: 4%.

[0045] Other schemes of this embodiment are all the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com