Method for reinforcing steel crane girders through carbon fiber sheets

A carbon fiber cloth and crane beam technology is applied in the field of reinforcing steel crane beams, which can solve the problems of structural internal force redistribution, long construction operation time, increased structural weight, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

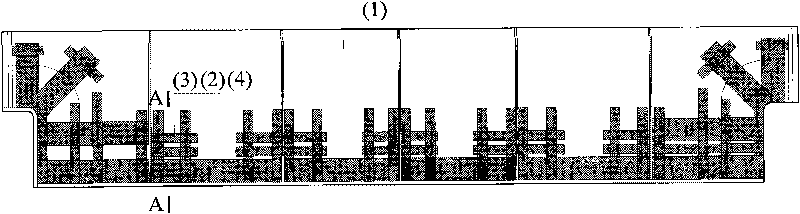

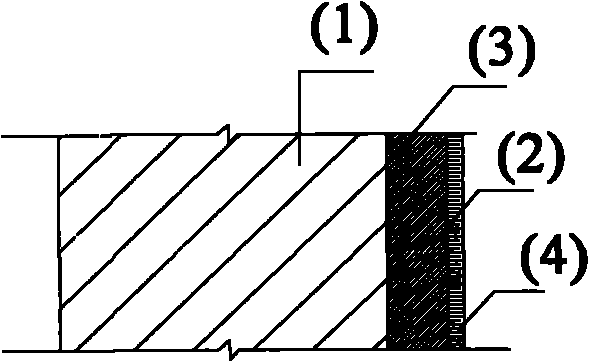

[0012] Embodiment one: see figure 1 and figure 2 , the carbon fiber cloth reinforced steel crane girder method, characterized in that: After applying structural glue 3 on the specified pasting part of the steel crane girder 1, paste carbon fiber cloth 2, and then brush fireproof mud 4 on the carbon fiber cloth 2.

Embodiment 2

[0013] Embodiment two: the present embodiment is basically the same as embodiment-, and the special feature is that the specific construction steps are as follows:

[0014] ① Prepare the matching structural glue 3. Grinding equipment, cutting carbon fiber cloth;

[0015] ② Derust and polish the surface of the steel crane beam 1, and clean it with acetone to make the surface to be pasted smooth;

[0016] ③ Prepare and paint the selected quick-setting structural glue 3 (this kind of glue can make the bonding effect of carbon fiber cloth and steel beam meet the design requirements in a short time);

[0017] ④Paste the cut carbon fiber cloth 2 to the reinforcement position, and use a scraper or roller brush to roll along the fiber direction several times to squeeze out the air bubbles, so that the structural adhesive 3 is fully saturated with the carbon fiber cloth 2;

[0018] ⑤ Brush a layer of structural glue 3 on the carbon fiber cloth 2, so that the carbon fiber cloth 2 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com