Compound fertilizer grain volume control system

A technology of size control and control system, which is applied in the direction of control/regulation system, multi-fluid ratio control, viscosity control, etc., can solve the problem that compound fertilizer particles cannot control the size of the particle volume well, and cannot achieve the purpose of fertilization, temperature or The pressure cannot be kept consistent all the time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

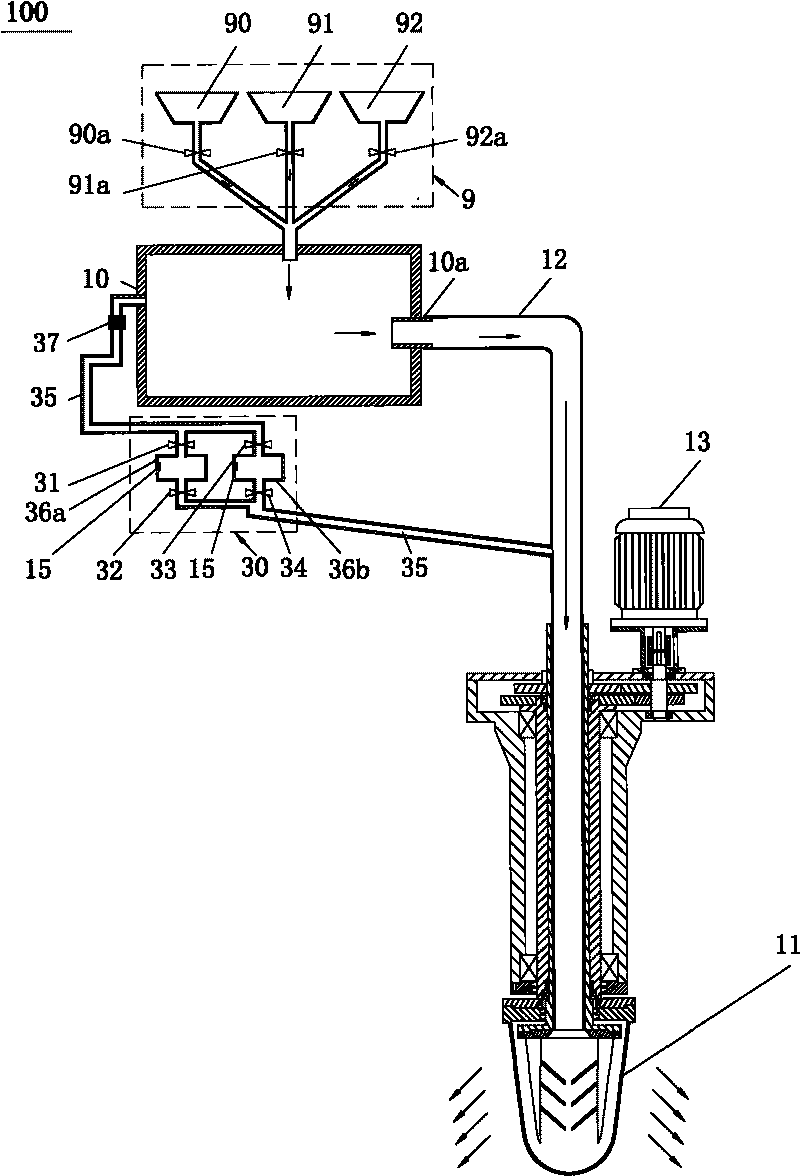

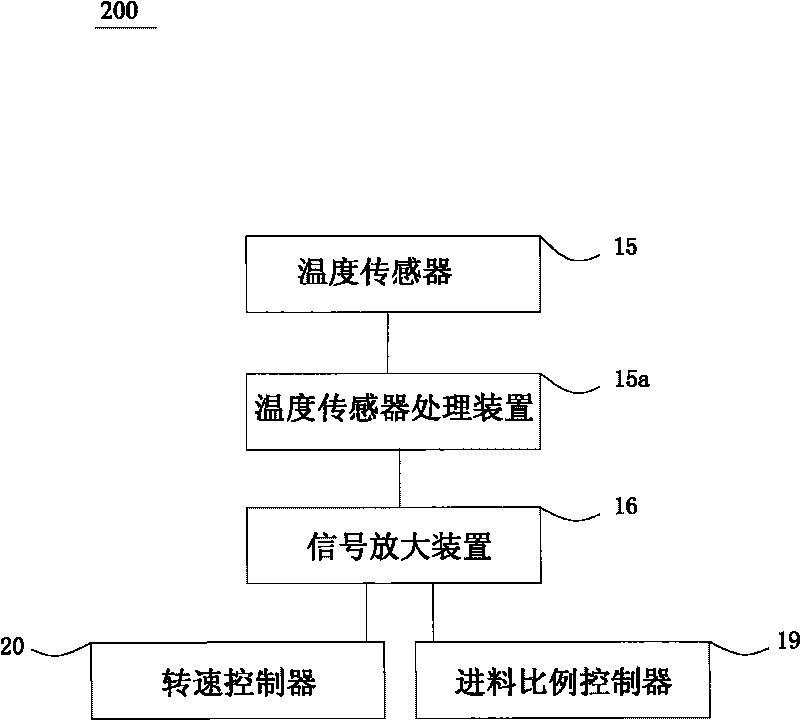

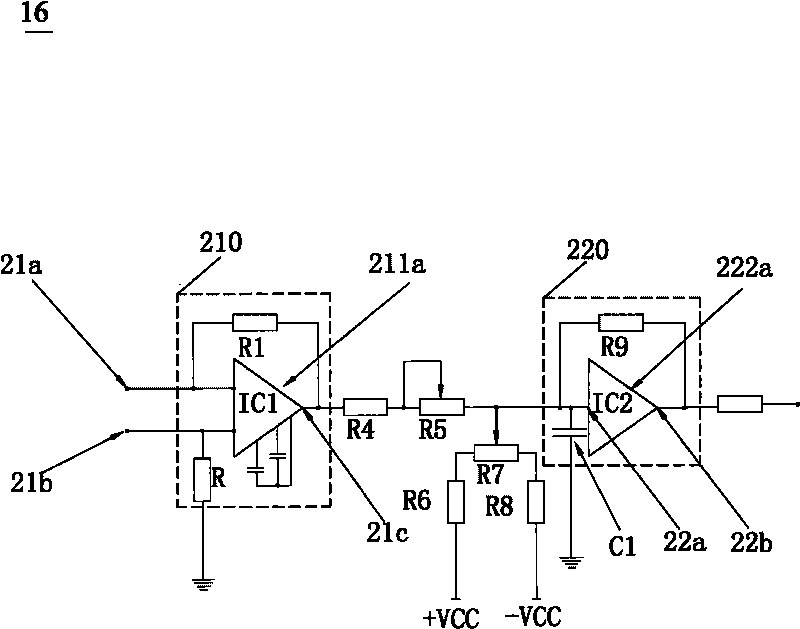

[0022] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as figure 1 , figure 2 and image 3As shown, the present invention provides a kind of compound fertilizer particle size control system 100, comprises feeding mechanism 9, material mixing tank 10, rotary nozzle 11, slurry conduit 12, control system 200 and rotary nozzle motor 13, described into The feed mechanism 9 feeds the material mixing tank 10, the mixing tank 10 has a discharge port 10a communicated with the slurry conduit 12, and one end of the slurry conduit 12 communicates with the discharge port 10a , the other end of the slurry conduit 12 communicates with the rotary nozzle 11, and the compound fertilizer slurry in the mixing tank 10 enters the rotary nozzle driven by the rotary nozzle motor 13 through the slurry conduit 12. 11 for granulation, the control system 100 is electrically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com