Method for preparing high-concentration fructose syrup

A fructose syrup, high-concentration technology, applied in the direction of fructose production, sugar production, glucose production, etc., can solve the problems of affecting the sweetness and taste of invert sugar, complicated process, etc., to ensure the appearance, simplify the process, and the method is simple and convenient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

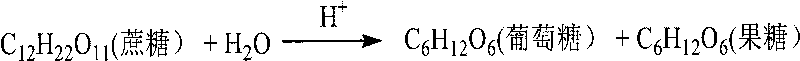

Method used

Image

Examples

Embodiment 1

[0034] Sucrose solution 500mL (sucrose concentration 48.73%, light transmittance measured at 420nm 45.4%), add 0.2% (m / v, 1.02g) concentrated sulfuric acid (pure) and 0.05% (m / v) powdered activated carbon of sucrose solution , the hydrolysis reaction was carried out at 75°C for 30 minutes, and the hydrolysis rate of sucrose was 99.32% (the light transmittance of the syrup was 76.9%, and the fructose content was 49.96%).

[0035] The syrup passes through the D315 anion exchange resin, the feed rate is 2BV / h, and the feed amount is 35BV, to remove acid radicals and a small amount of pigment, and to detect SO in the syrup 4 2- Concentration, SO 4 2- ≤100ppm; then pass through 732 cation exchange resin, the feed rate is 4BV / h, the feed amount is 80BV, adjust the pH value to 6.0~6.5, Ca 2+ , Mg 2+ The concentration is lower than 10ppm, and the fructose syrup with a concentration of 50.74% is obtained.

Embodiment 2

[0037] Sucrose solution 1000mL (sucrose concentration 59.32%, light transmittance measured at 420nm 44.7%), add 0.5% (5.1g) of concentrated sulfuric acid (pure) and 0.8% powdered activated carbon, hydrolyze at 50°C, hydrolyze 15 , 30, and 45 minutes, the hydrolysis rates of sucrose were 97.02%, 99.78%, and 99.84%, respectively.

[0038]The syrup passes through the D301 type anion exchange resin, the feed rate is 2BV / h, the feed amount is 40BV, the acid radical and a small amount of pigment are removed, and the SO in the syrup is detected 4 2- Concentration, SO 4 2- ≤100ppm; then pass through 734 cation exchange resin, the feed rate is 5BV / h, the feed amount is 80BV, adjust the pH value to 6.5~6.8, Ca 2+ , Mg 2+ The concentration is lower than 10ppm, and the fructose syrup with a concentration of 61.97% is obtained.

Embodiment 3

[0040] Sucrose solution 20L (sucrose concentration 51.26%, transmittance 43.5%, Ca 2+ , Mg 2+ Concentrations are 64ppm, 11ppm), add 0.5% (102g) concentrated sulfuric acid (pure) and 0.4% powdered activated carbon, hydrolyze at 60°C for 60min, the hydrolysis rate of sucrose is 99.47%.

[0041] The syrup passes through 900mL of D315 type anion exchange resin with a feed rate of 2BV / h and a feed volume of 38BV, and then passes through 200mL of 732 cation exchange resin with a feed rate of 5BV / h and a feed volume of 100BV to adjust the pH value To 6.7-7, fructose syrup is obtained.

[0042] Concentration of fructose syrup is 53.06%, pH is 6.8, SO 4 2- Concentration≤125ppm, Ca 2+ , Mg 2+ The concentration is lower than 5ppm, and the light transmittance is 91.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com