Fire-free method for repairing leakage of pipeline

A pipeline leakage and pipeline technology, applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of long production time, cooling, waste of gas, etc., and achieve good chemical corrosion resistance, oil resistance and cold resistance Good, strong and durable adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

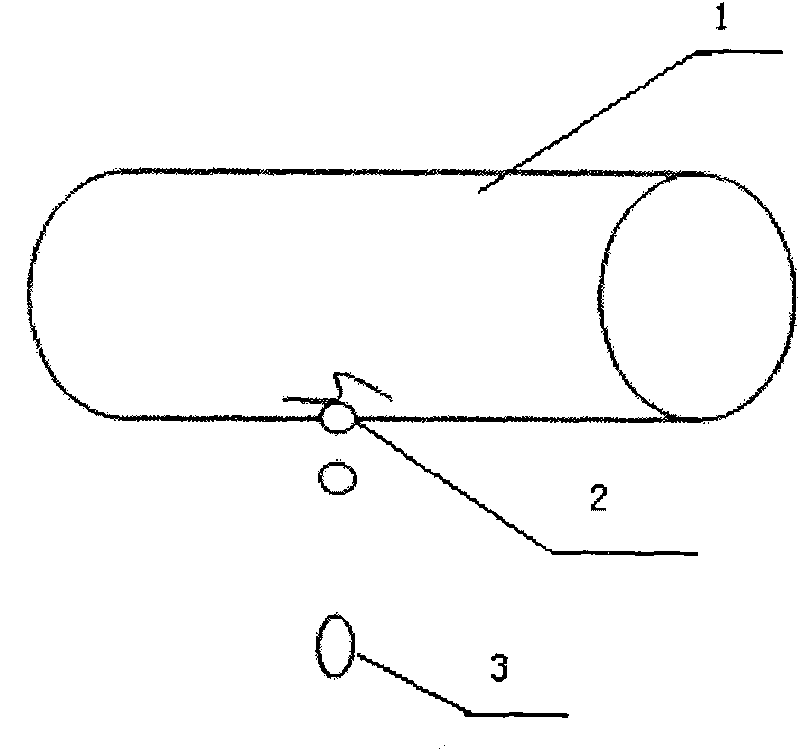

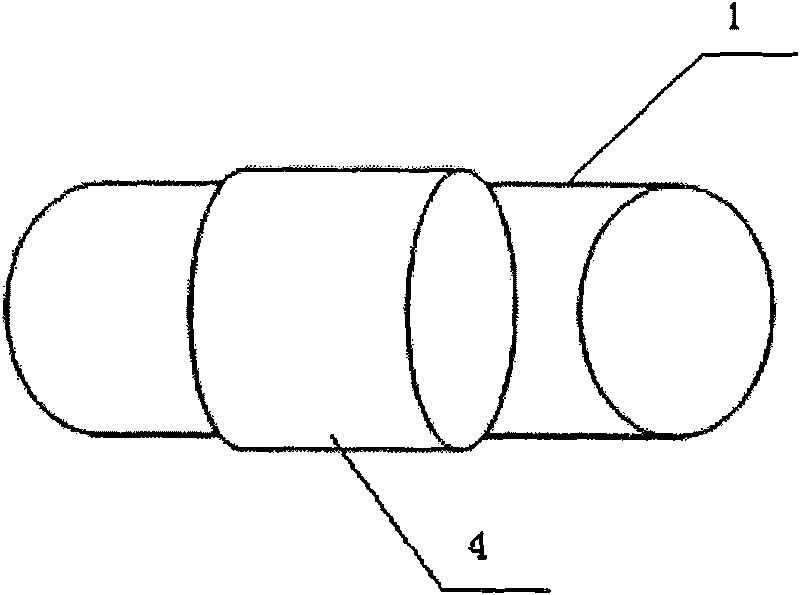

[0019] (1) Measure the size of the pipeline leak, cut a piece of glass steel plate (purchased in the market), the length is 2 meters longer than the length of the leak, and the width is 5cm longer than the circumference of the pipeline;

[0020] (2) Clean the surface of the leaking part of the pipeline, wrap the leaking part of the pipeline with the cut glass steel plate, and wrap the overlapped part on the upper part of the pipeline, tie the two ends and the middle of the glass steel plate firmly with iron wire, and use dry Resin powder seals both ends of the glass steel plate tightly;

[0021] (3) Weigh epoxy resin, curing agent and accelerator in a certain proportion, mix them and add appropriate amount of dry resin powder to mix evenly; the ratio of epoxy resin, curing agent and accelerator is 1:1:1 by weight After mixing, the mixture is mixed with dry resin powder in a weight ratio of 1:2;

[0022] (4) smear the mixture obtained in step (3) at both ends of the glass stee...

Embodiment 2

[0026] (1) Measure the size of the pipeline leak, cut a piece of glass steel plate, the length is 1.5 meters longer than the length of the leak, and the width is 2cm longer than the circumference of the pipeline;

[0027] (2) Clean the surface of the leaking part of the pipeline, and wrap the leaking part of the pipe with the cut glass steel plate. The iron wire is bound firmly, and the two ends of the glass steel plate are sealed tightly with dry resin powder;

[0028] (3) Weigh epoxy resin, curing agent and accelerator in a certain proportion, mix them and add appropriate amount of dry resin powder to mix evenly; the ratio of epoxy resin, curing agent and accelerator is 1:1:1 by weight After mixing, the mixture is mixed with dry resin powder in a weight ratio of 1:2;

[0029] (4) smear the mixture obtained in step (3) at both ends of the glass steel plate and the outer surface of the whole glass steel plate;

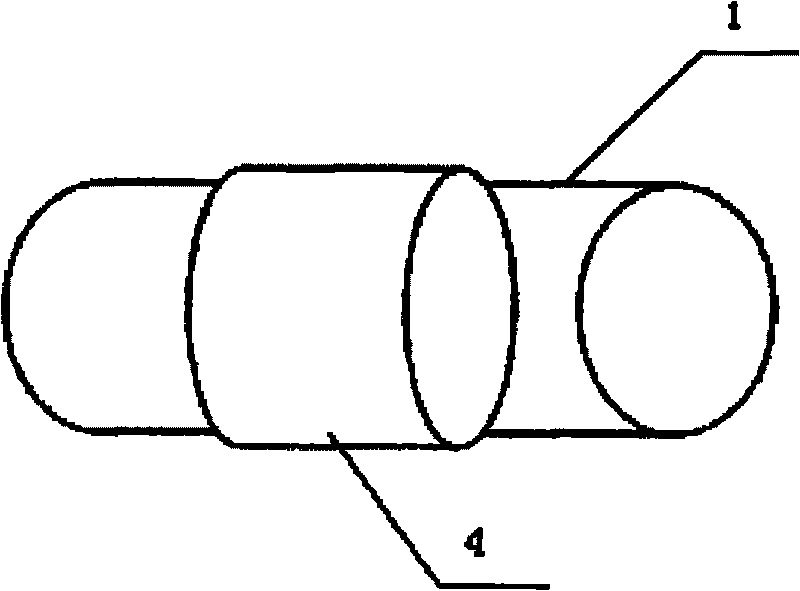

[0030] (5) Wrap the glass steel plate with glass cloth for one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com