Circulating gasifying and pyrolyzing incinerator system and incinerating method

An incinerator and dry distillation technology, applied in the field of incinerators, can solve the problems of insufficient pyrolysis of cooling tar and oil, inability to complete gasification in a short time, delaying the time of dry distillation and degasification, etc., so as to improve the comprehensive utilization rate and arrange Effect of burning time and reasonable burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

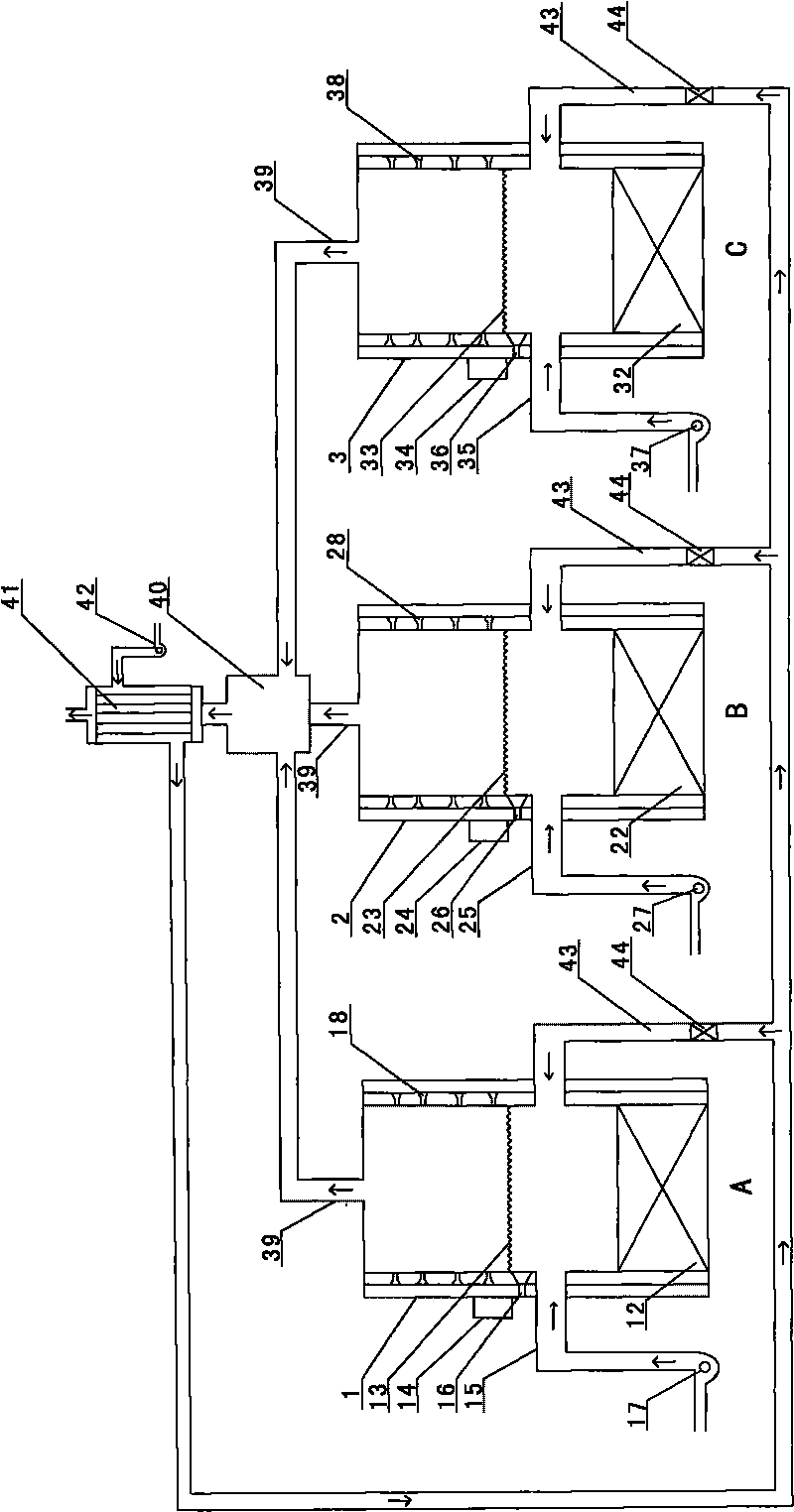

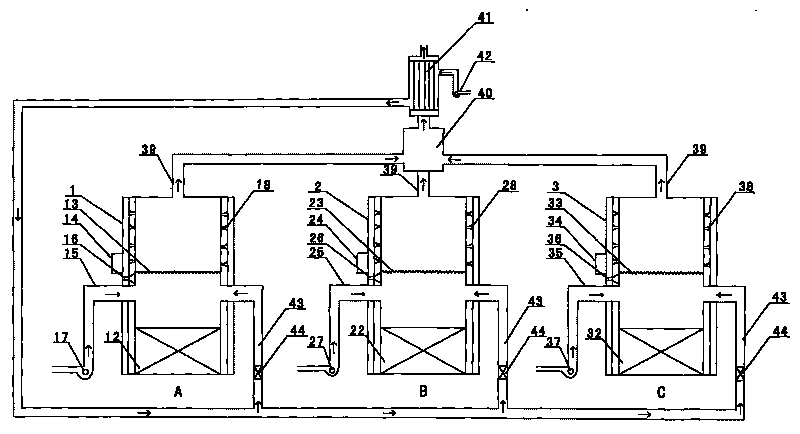

[0016] The circulating gasification dry distillation incinerator is composed of furnace A, furnace B and furnace C, wherein furnace A is equipped with a shell 1, ash removal port 12, fire grate 13, air control system 14, air duct 15, ignition burner 16, Composed of fan A17 and high-pressure air nozzle 18; furnace B is equipped with shell 2, ash outlet 22, grate 23, air control system 24, air duct 25, ignition and combustion aid 26, fan B27, high-pressure air nozzle 28 Composition; C furnace is equipped with shell 3, ash outlet 32, fire grate 33, air control system 34, air duct 35, ignition and combustion aid 36, fan C37, high-pressure air nozzle 38; A furnace, B furnace, C Furnace tops are equipped with tail gas outlet 39, tail gas outlet 39 communicates with secondary combustion chamber 40, secondary combustion chamber 40 communicates with heat exchanger 41, heat exchanger 41 is provided with fan D42, heat exchanger 41 communicates with A furnace, B furnace Furnace C and furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com