High efficiency piezoelectric ceramic material with low sintering temperature and preparation technology thereof

A technology of piezoelectric ceramics and sintering temperature, which is applied in the field of high-efficiency piezoelectric ceramic materials with low sintering temperature and its preparation technology, can solve the problem that it cannot be used to manufacture high-power piezoelectric ceramic speakers, cannot be used to prepare high-power multi-layer speakers, Low piezoelectric performance and other problems, to achieve the effect of low cost, improved piezoelectric performance and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

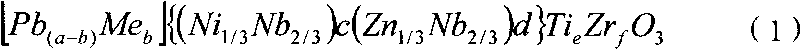

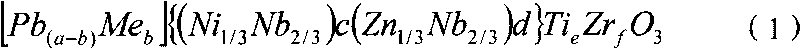

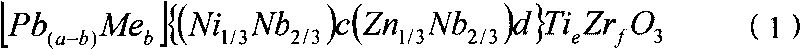

[0040] Pb 0.97-0.10 Sr 0.10 (Ni 1 / 3 Nb 2 / 3 ) 0.05 (Zn 1 / 3 Nb 2 / 3 ) 0.15 Zr 0.35 Ti 0.45 o 3 (1)

[0041] The main component is Pb 3 o 4 , ZrO 2 、TiO2 , SrCO 3 、NiCO 3 , ZnO, Nb 2 o 5 , weighed according to the formula of chemical formula (1), taking the above-mentioned main component gross weight as 100%, add the following additives: 0.008% H 3 BO 3 , 0.60% Sb 2 o 5 , 0.10% Bi 2 o 3 , 0.03% Li 2 CO 3 , 0.2% CuO;

[0042] Then, the above-mentioned ceramic raw materials are put into a planetary ball mill together with deionized water, mixed for 6-10 hours, and discharged, and dried, wherein during the planetary ball milling process, the mixture: ball: water = 1: 3.5: 0.7;

[0043] Pre-fire the mixed raw materials at 780°C-800°C for 2-3 hours, mix the obtained pre-fired powder with deionized water, and use a planetary ball mill for 6-10 hours until d 50 ≤0.40μm, d 90 ≤0.60μm, drying;

[0044] Add polyvinyl alcohol solution with a weight ratio of 5% t...

Embodiment 2

[0051] Pb 0.995-0.08 Sr 0.05 Ba 0.03 (Ni 1 / 3 Nb 2 / 3 ) 0.08 (Zn 1 / 3 Nb 2 / 3 ) 0.12 Ti 0.40 Zr 0.40 o 3 (2)

[0052] The main component is Pb 3 o 4 , ZrO 2 、TiO 2 , SrCO 3 、BaCO 3 、NiCO 3 , ZnO, Nb 2 o 5 , weighed according to the formula of chemical formula (2), taking the above-mentioned main component gross weight as 100%, add the following additives: 0.05% SiO 2 and 0.05% H 3 BO 3 mixture, 0.30% Sb 2 o 3 , 0.40% Bi 2 o 5 , 0.15% Li 2 CO 3 , 0.15% CuO;

[0053] Then, the above-mentioned ceramic raw materials are put into the planetary ball mill together with deionized water, mixed for 6-10 hours, then discharged, and dried, wherein during the planetary ball milling process, the mixture: ball: water = 1: 3.5: 0.9;

[0054] Pre-fire the mixed raw materials at 780°C-800°C for 2-3 hours, mix the obtained pre-fired powder with deionized water, and use a planetary ball mill for 6-10 hours until d 50 ≤0.40μm, d 90 ≤0.60μm, drying;

[0055] Add polyviny...

Embodiment 3

[0062] Pb 1.05-0.03 Ba 0.03 (Ni 1 / 3 Nb 2 / 3 ) 0.15 (Zn 1 / 3 Nb 2 / 3 ) 0.05 Ti 0.45 Zr 0.35 o 3 (3)

[0063] The main component is Pb 3 o 4 , ZrO 2 、TiO 2 、BaCO 3 、NiCO 3 , ZnO, Nb 2 o 5 , weighed according to the formula of chemical formula (3), taking the above-mentioned main component gross weight as 100%, add the following additives: 0.1% SiO 2 , 0.10% Sb 2 o 5 , 0.60% Bi 2 o 3 , 0.2% Na 2 CO 3 , 0.08% CuO;

[0064] Then, the above-mentioned ceramic raw materials are put into a planetary ball mill together with deionized water, mixed for 6-10 hours, then discharged, and dried, wherein during the planetary ball milling process, mixture: ball: water = 1: 3.5: 0.8;

[0065] Pre-fire the mixed raw materials at 780°C-800°C for 2-3 hours, mix the obtained pre-fired powder with deionized water, and use a planetary ball mill for 6-10 hours until d 50 ≤0.40μm, d 90 ≤0.60μm, drying;

[0066] Add polyvinyl alcohol solution with a weight ratio of 5% to 10% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com