Method for sealing foundation pit pressure reduction well

A technology for pressure-reducing wells and foundation pits, which is applied to wellbore/well components, earthwork drilling, sealing/isolation, etc., which can solve the problems of increasing the risk of water leakage and no grouting sealing measures, etc. Effects of simplicity, cost increase, and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

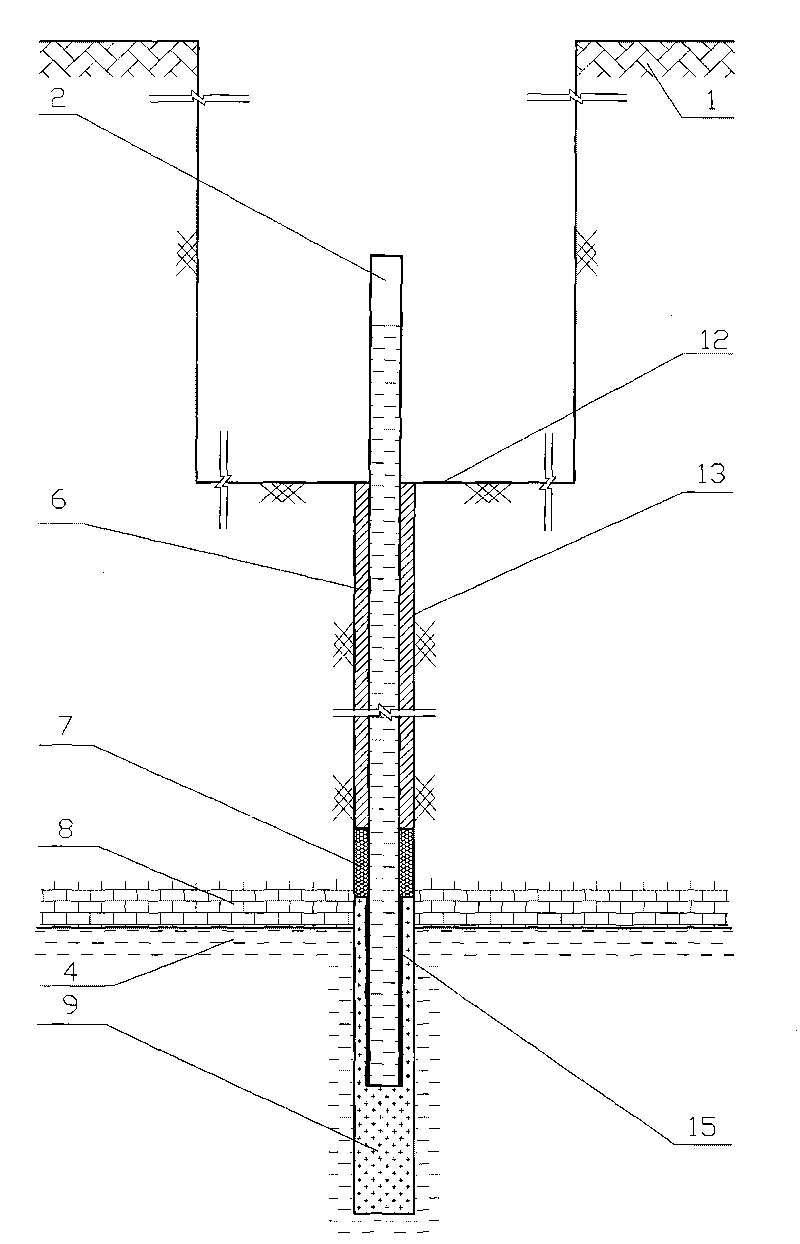

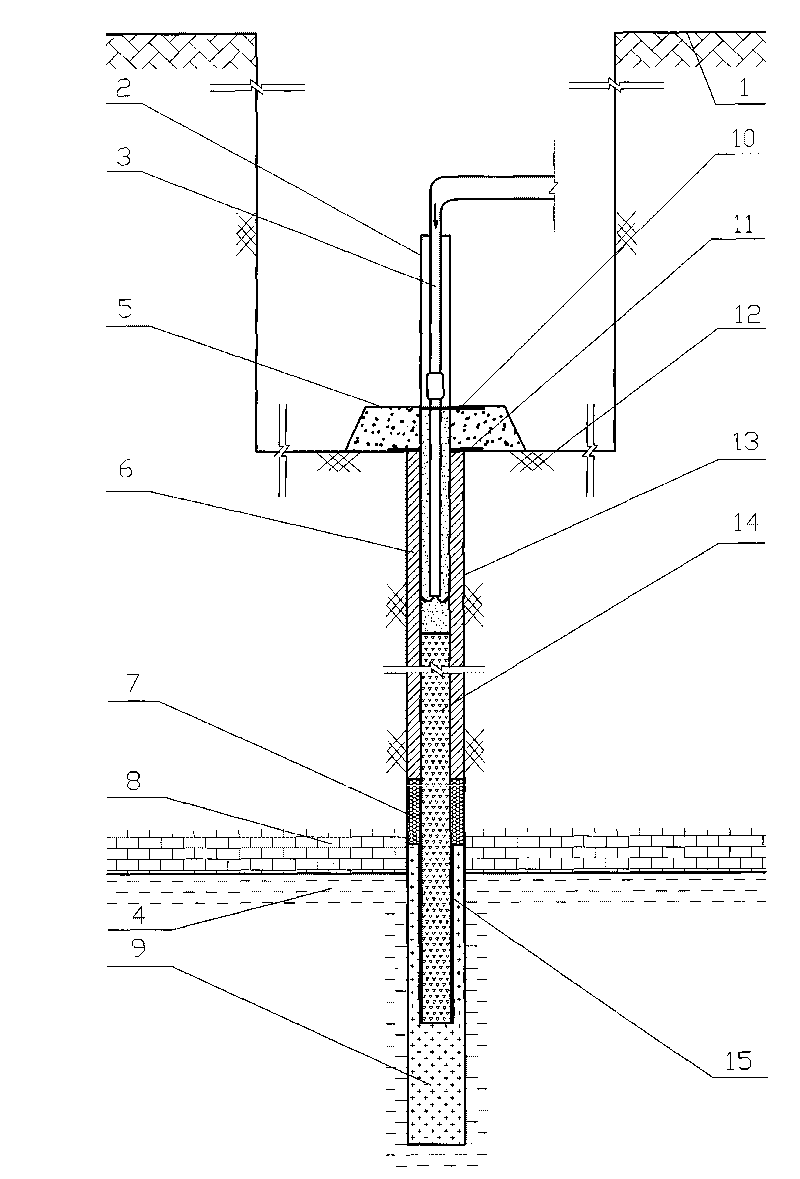

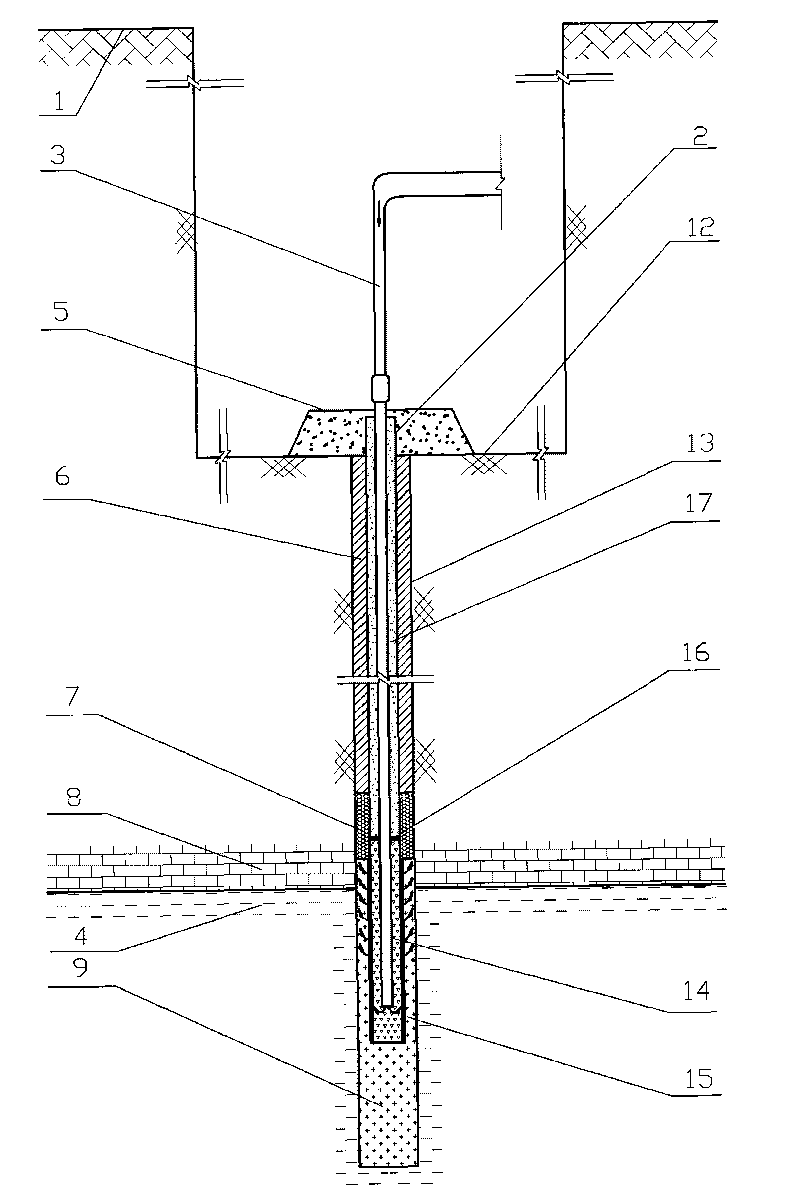

[0053] The present invention will be further described below in conjunction with accompanying drawing.

[0054] figure 1 Among them, the step-down well includes a well hole 13 opened downward from the foundation pit floor 12, and a well pipe 2 is arranged in the well hole 13. The diameter of the well hole 13 is generally 500-600mm, and the diameter of the well pipe 2 is generally 200-250mm. The top of the well pipe 2 extends out of the well hole 13, and the bottom end of the well pipe 2 is a closed end. The side wall of the well pipe 2 located in the confined aquifer I4 is evenly distributed with filter holes, and the well pipe 2 of the filter hole section is wound outside There is a filter screen 15, which is filled with sand filter layer 9, clay ball backfill layer 7 and clay backfill layer 6 sequentially from bottom to top, between the well pipe 2 and the well hole 13, wherein the top surface of the sand filter layer 9 is located at the stable water-proof Within the range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com