Method for reinforcing concrete structure by using prestressed fiber cloth

A fiber cloth and prestressing technology, which is applied in building maintenance, building construction, and building material processing, can solve the problems of uneven tensioning and anchoring of fiber cloth, complicated construction technology, and reduced work efficiency, so as to achieve force application Uniformity, simple and easy operation, shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

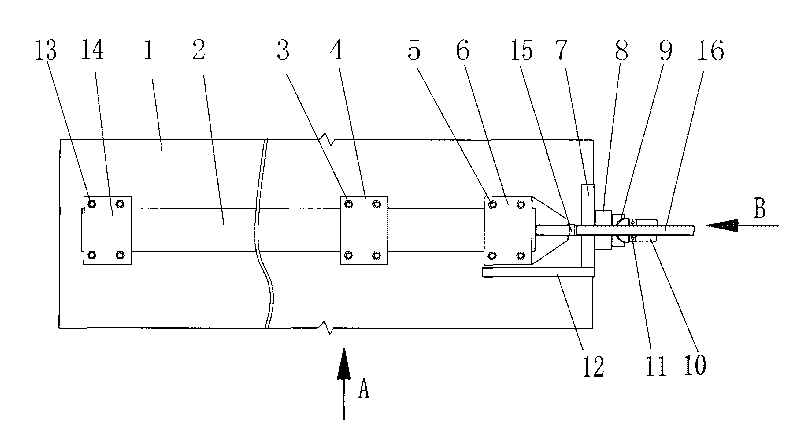

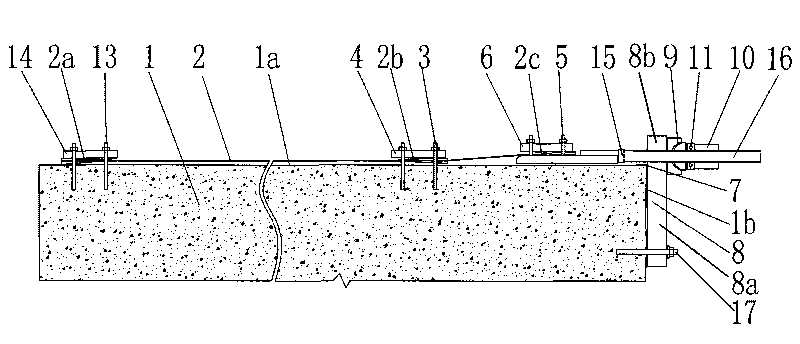

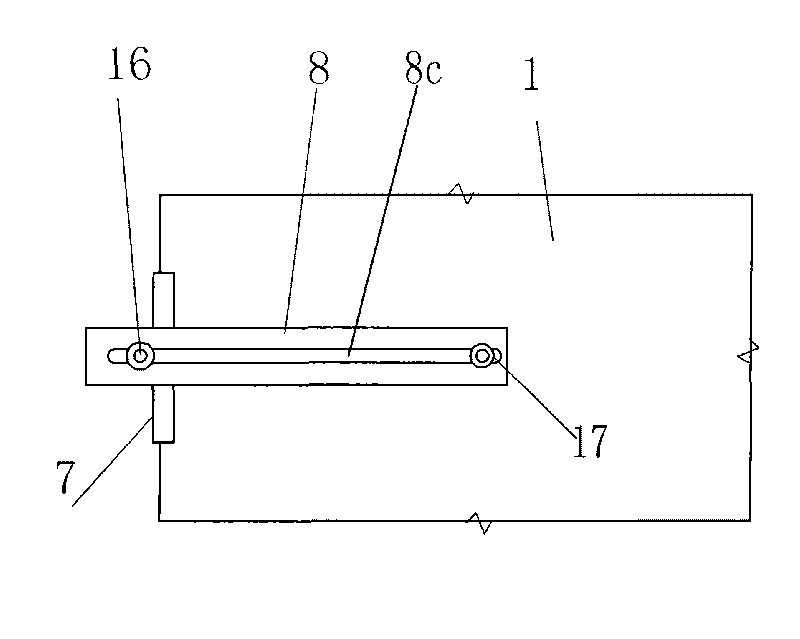

[0029] figure 1 It is a structural schematic diagram after the tensioning equipment is installed for the present invention, figure 2 for figure 1 A to the view, image 3 for figure 1 B direction view, as shown in the figure: the method for reinforcing the concrete structure with the prestressed fiber cloth of the present embodiment comprises the following steps:

[0030] a. Arranging tensioning equipment: the tensioning equipment includes a tensioning reaction beam 8, a tension rod 16 and a tensioning connecting plate 6, and the tensioning reaction beam 8 includes a fixed beam section 8a and a tensioning beam section 8b, The fixed beam section 8a is fixedly arranged on the surface 1b of the concrete column adjacent to the surface 1a of the concrete column 1 to be reinforced, the tension beam section 8b extends out of the surface 1b of the concrete column along the transverse direction, and the tension rod 16 is parallel to the concrete column to be reinforced One end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com