Microwave low-loss waveguide vacuum window

A vacuum window and low-loss technology, applied to waveguide devices, electrical components, circuits, etc., to reduce loss and improve overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

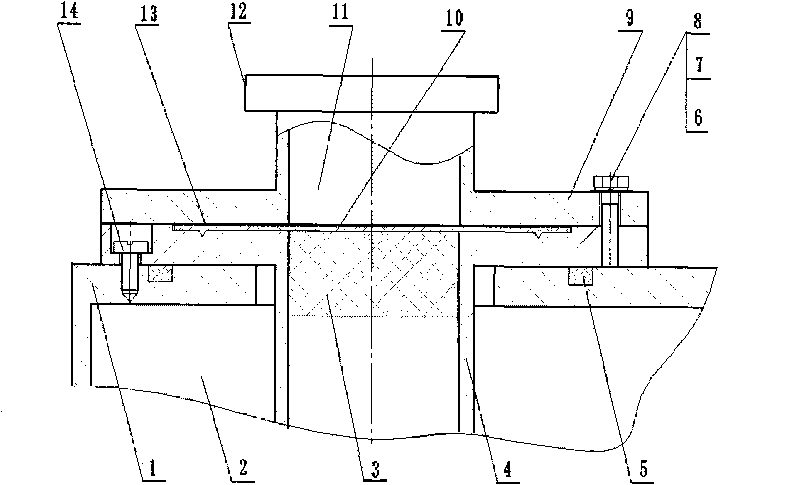

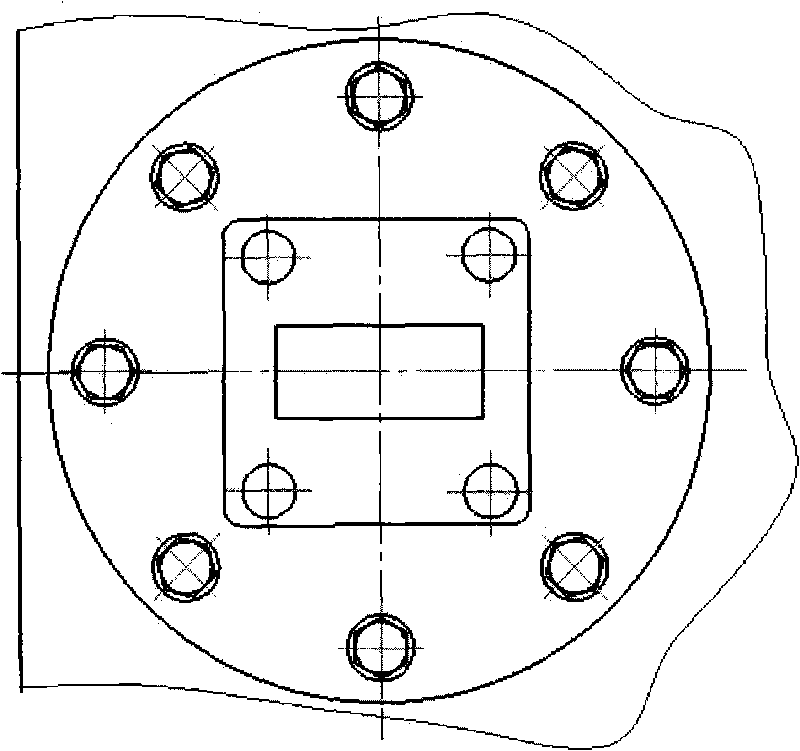

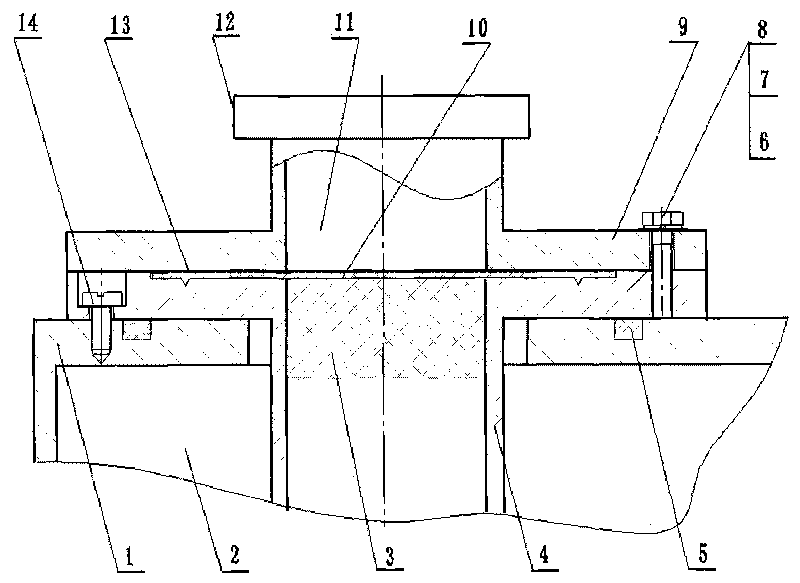

[0011] see figure 1 , 2 , the vacuum cover 1 is installed in the shell of the refrigeration system, the lower base of the waveguide cavity 4 is connected with the vacuum cavity through 8 screws 14 and the sealing ring 5, the hard foam 3 is bonded to the waveguide port of the lower base of the waveguide cavity 4 with 703 silica gel, Place the polytetrafluoroethylene pad 10 and the polyimide film 13 on the lower seat 4 of the waveguide cavity, install the upper seat 9 of the waveguide cavity, and fasten the upper and lower seats of the waveguide cavity with 8 hexagonal screws 6 plus spring washers 7 and flat washers 8, The installation of microwave low-loss waveguide vacuum window is completed. Microwave low-loss waveguide vacuum windows in various frequency bands can be designed according to the structure shown in the figure, and the highest window frequency can reach the millimeter wave frequency band.

[0012] Microwave low-loss waveguide vacuum window, the normal temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com