Boost type converter for realizing high-gain voltage multiplication by coupling inductors

A coupled inductance, high gain technology, applied in the field of high gain doubler boost converters, can solve the problems of inability to reduce the voltage stress of the power switch tube, not expanding the gain of the converter, complex coupled inductance structure, etc., and achieve reverse recovery Good characteristics, simple structure, small conduction voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

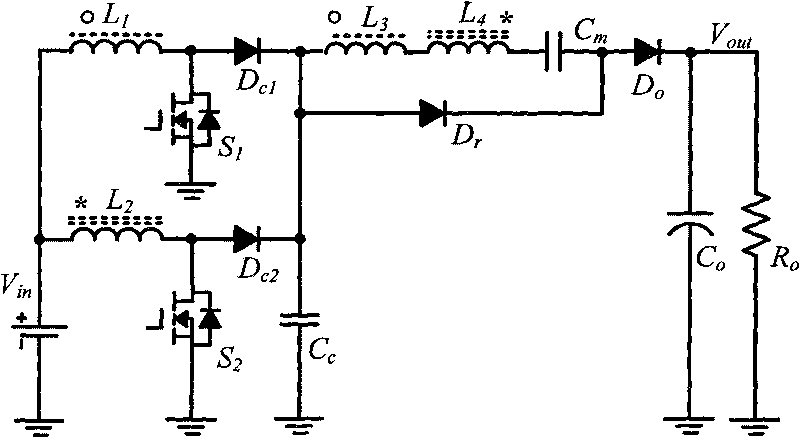

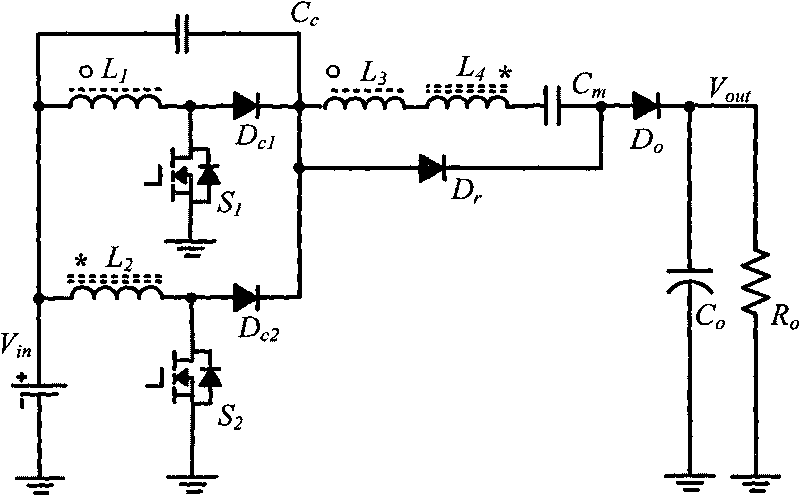

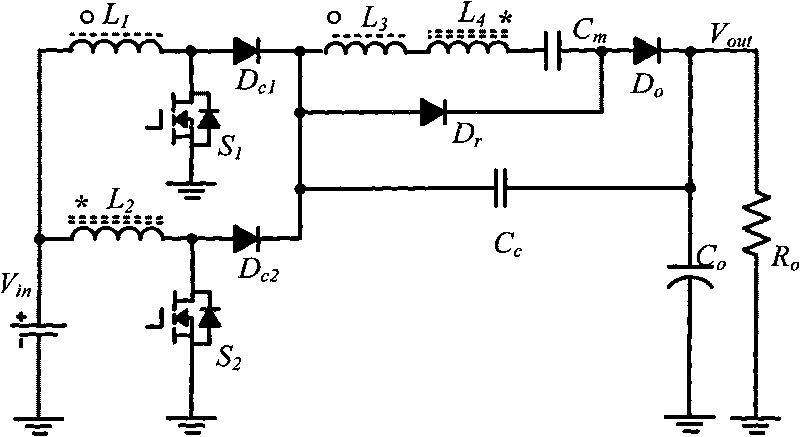

[0021] see figure 1 , the coupled inductor of the present invention implements a high-gain voltage doubler boost converter, including three parts: a Boost voltage booster circuit unit, a voltage doubler circuit unit and an output circuit unit.

[0022] In the Boost circuit unit in the converter, the first winding L 1 The first end and the second winding L 2 The first terminal of the power supply Vin is connected to the positive pole of the power supply Vin, and the first winding L 1 The second terminal of the first switch tube S 1 connected to the drain of the second winding L 2 The second terminal and the second switch tube S 2 connected to the drain of the first switching tube S 1 source and the second switch S 2 The source and the cathode of the power supply Vin are connected, the first clamping diode Dc 1 The anode of the first switching tube S 1 The drain is connected, the second clamping diode Dc 2 The anode of the second switching tube S 2 The drain is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com