Method and device for separating surfactant from dilute solution

A technology for surface active substances and separation methods, applied in the field of separation of surface active substances, can solve the problems of lowering the concentration of active substances, affecting the efficiency of foam separation, and decreasing the driving force of mass transfer, achieving high foam separation, improving the retention rate, eliminating the The effect of bubble backmixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

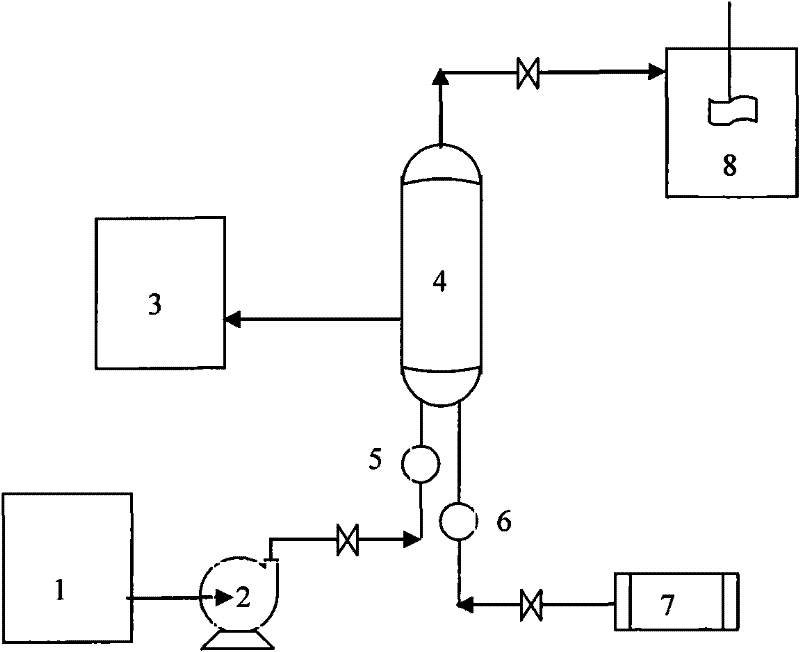

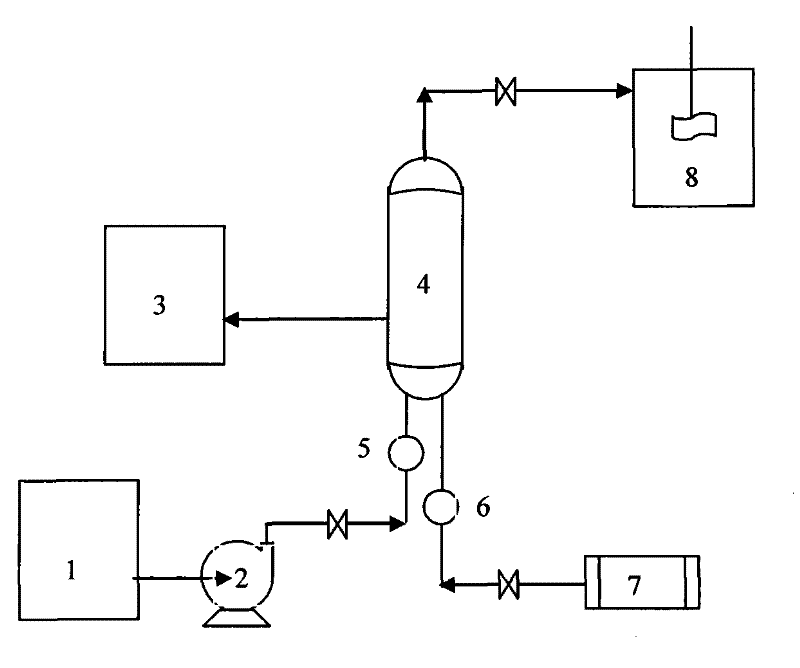

Image

Examples

Embodiment 1

[0020] The tubular membrane module adopts an ultrafiltration membrane. At a pressure of 0.05MPa and a volume ratio of gas to liquid of 0.4:1, the aqueous solution of sodium dodecylbenzenesulfonate with a concentration of 25ppm is treated with a rejection rate of 64.9%.

Embodiment 2

[0022] The tubular membrane module adopts a nanofiltration membrane. At a pressure of 0.6MPa and a volume ratio of gas to liquid of 0.35:1, the aqueous solution of ammonium perfluorooctanoate with a concentration of 1200ppm is treated with a rejection rate of 98.1%.

Embodiment 3

[0024] The tubular membrane module adopts reverse osmosis membrane, under the pressure of 1.2MPa, the volume ratio of gas and liquid is 0.3:1, and the aqueous solution containing divalent lead ion with a concentration of 80ppm is complexed with sodium lauryl sulfate surfactant , The rejection rate reaches 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com